Recent advances in heterogeneous hydrosilylation of unsaturated carbon-carbon bonds

-

* Corresponding authors.

E-mail addresses: ctang@hust.edu.cn (C. Tang), feng.chen@yzu.edu.cn (F. Chen).

Citation:

Heng Yang, Zhijie Zhou, Conghui Tang, Feng Chen. Recent advances in heterogeneous hydrosilylation of unsaturated carbon-carbon bonds[J]. Chinese Chemical Letters,

;2024, 35(6): 109257.

doi:

10.1016/j.cclet.2023.109257

Organosilicon compounds are an important class of compounds, which are widely used in materials science, medicinal chemistry, and organic synthesis [1–8]. At present, many research methods have been developed for the synthesis of silicon-containing compounds [9]. Among them, hydrosilylation reactions of unsaturated bonds, such as alkene and alkyne, are studied intensively due to the high atomic economy and wide range of starting materials. In 1947, Sommer reported the peroxide catalyzed the addition reaction of trichlorosilane to 1-octene [10]. In the 1950s, Speier's catalyst was developed as a very effective homogeneous catalyst, which was a big breakthrough in hydrosilylation reactions [11]. The Karstedt's catalyst, which showed high activity with wide substrate scope was reported in 1973 and broadly used in silicone industrial production [12]. Later, transition metals based homogeneous catalysts, such as rhodium, platinum, palladium, ruthenium, and even non-noble metal cobalt, nickel and iron [13], have been widely studied to improve the catalytic performance and reduce the cost. Besides, homogeneous rare-earth metals complexes such as samarium, scandium, yttrium and lanthanum are also developed for the unsaturated bonds hydrosilylations [14–22]. Ligand is very important for homogeneous catalysis while it can influence the activity. Most ligands for the hydrosilylations are expensive and sensitive. On the other hand, the catalysts in homogeneous catalysis are difficult to separate from the reaction mixture and reuse. Therefore, it is still a challenge to find a more excellent catalytic system to achieve high-efficiency and low-cost hydrosilylation reactions.

Heterogeneous catalysis is important because it enables large scale in industrial production. Generally, the heterogeneous catalysts can be recovered easily and reused with long lifetimes. This will reduce the cost of catalysts, especially noble metals, and simplify the separation process effectively. The existence of this driving force has led to a great deal of research in the field of exploring heterogeneous hydrosilylations. Supports are crucial for the activity and selectivity of the reactions. The most popular supports for the catalyst preparation are silica, carbon, metal oxide, organic polymer and metal-organic-frameworks (MOFs).

In this review, we summarized the recent development of heterogeneous catalysts for alkene, alkyne, and allene hydrosilylations. We focus on the following support-based catalysts: silicon, molecular sieve, carbon material, metal oxide, organic polymer, and MOFs materials.

In 2003, Fang et al. prepared a silica-supported Karstedt (Pt)-type catalyst with high catalytic activity for hydrosilylation Me2Ph SiH with styrene at room temperature [23]. Vinylsiloxane groups could bond to the surface of fume silica after the treatment vinyltriethoxysilane. Then treatment with an aqueous solution of H2PtCl6 gives the corresponding heterogeneous Karstedt-like catalyst. The recyclability of this catalyst is also good, and no significant loss of catalytic activity after five runs.

In 2008, Marciniec et al. reported cyclooctadiene ligand-containing rhodium siloxide complex immobilized with silanol groups on silica surface Aerosil 200 [24,25]. This single-site complex showed good activity in hydrosilylation of heptamethyltrisiloxane with 1-heptene, vinylheptamethyltrisiloxane and methyleugenol. It offered 20 recycling runs without loss of activity and selectivity in hydrosilylation of vinylheptamethyltrisiloxane with heptamethyltrisiloxane. The detailed mechanism studies disclosed that the pathway of hydrosilylation catalyzed by silica-supported rhodium siloxide complexes is different from homogeneous complexes system (Fig. 1). In 2009, the mononuclear rhodium-silica-phosphine precursor was also used to fix on the surface of silica Aerosil 200 [26]. The catalytic activity in the hydrosilylation of 1-hexadecene with heptamethyltrisiloxane was higher than that of the catalyst without phosphorus ligand, and the catalytic activity did not decrease after 10 cycles (Fig. 2).

In 2017, Motokura et al. modified the catalyst of cyclooctadiene rhodium complex loaded on the surface of silicon dioxide, introducing tertiary amine ligand on its surface, which can provide electrons to rhodium complex and promote oxidation addition and insertion steps [27]. The catalyst can catalyze the hydrosilylation reaction of long-chain alkenes with various silanes. Within 24 h, the TON is close to 1900000, showing higher activity than the catalyst without tertiary amine ligand. And it can still maintain high activity after five cycles. In order to explain the effect of the introduction of tertiary amine on the structure and reactivity of the rhodium complex on the surface, several spectroscopic techniques, such as Rh K-edge XAFS measurements, dynamic nuclear polarization enhanced solid-state 15N NMR spectroscopy, and in situ FTIR analyses were performed [28]. It is found that the immobilization of amine can significantly improve the dissociation of ligand COD, and the change of COD microstructure can greatly affect the dissociation of rhodium, which can promote the process of ligand exchange, including the insertion of hydrogen-silicon bond, so as to improve the activity of catalyst. In 2019, they synthesized a dual-functional catalyst by loading rhodium complex and iodized quaternary ammonium salt on silicon dioxide [29]. The catalyst can realize one-pot hydrosilylation and cycloaddition reaction of carbon dioxide. Mechanism studies indicate that the increase in the rate of hydrosilylation reaction may be due to the dissociation of COD ligand and rhodium precursor and the provision of electrons by iodide to rhodium center (Fig. 3) [30].

A fumed silica-supported nitrogenous platinum complex was prepared from cheap γ-aminopropyltriethoxysilane immobilization, followed by treatment with hexachloroplatinic acid (Fig. 4) [31]. The characterization disclosed an interaction of NH2 groups combining with Pt metal in 'SiO2'-NH2-Pt, indicating a coordination bond between N and Pt. It is an efficient catalyst for the hydrosilylation of olefins with triethoxysilane, and it can be reused several times via simple filtration without any noticeable activity loss.

Li et al. also developed a silica supported ethylenediaminetetraacetic acid (EDTA) platinum complex catalyst SiO2-EDTA-Pt to realize solvent-free hydrosilylation of 1-hexene and methyldichlorosilane with high catalytic activity (Fig. 5a) [32]. This catalyst could be recycled 12 times without noticeable loss of catalytic activity. They reported other similar catalysts by loading Pt onto silica particles modified with polycarboxylic acid groups such as diethylenetriaminepentaacetic acid (DTPA) and nitrolotriacetic acid (NTA) (Figs. 5b and c) [33]. The hydrosilylation activity of linear olefins (1-heptene, 1-octene, 1-decene) or cyclic olefins (cyclohexene, norbornene) with methyldichlorosilane is better than homogeneous platinum catalyst. The Pt catalyst can activate the double bond of olefin to generate the alkene-Pt complex. Then olefin is inserted into the Pt–H bond easily in the presence of methyldichlorosilane (Fig. 6) [34].

Pagliaro et al. reported the preparation of 0.5–1.0 mol% Pt(0) nanoparticles (4–6 nm) encapsulated within a sol–gel porous methyl-modified ORMOSIL [35]. This solid catalyst can selectively mediate the hydrosilylation of olefins with triethoxysilane at room temperature or 65 ℃. However, the catalyst failed in solvent-free alkene hydrosilylation. In 2019, they reported a silica catalyst with platinum nanoparticles to realize solvent-free alkene hydrosilylation. The substrate scope under this catalytic system is broad (Scheme 1). This catalyst can be recycled several times. By comparing the prepared Pt catalyst with several commercially supported platinum catalysts, it is found that the performance of the catalyst prepared by this method is higher than that of commercial catalysts [36].

A Pd-Cu bimetallic catalyst in an alloy form was synthesized and applied for alkynes hydrosilylation with Et3SiH without additional ligand [37]. Various vinylsilanes were obtained with excellent yield and selectivity under mild conditions. The arylacetylenes with electron-withdrawing groups show better selectivity than substrates with electron-donating groups (Scheme 2). The extraordinary catalytic performance is attributed to the ultra-small size and homogeneous distribution of the bimetallic nanoparticles. More Pd centers were exposed at the catalyst surface, leading to a low catalyst loading for the hydrosilylation reaction. Furthermore, alloying palladium with cheap copper also can reduce the cost of catalysts, providing better access to green and sustainable chemistry.

In 2010, Cai et al. reported a new type of catalyst that immobilized γ-mercaptopropyltriethoxysilane on mesoporous material MCM-41 followed by treatment with potassium chloroplatinate (MCM-41-SH-Pt) (Fig. 7a). The catalyst is effective for the hydrosilylation reaction between olefin and triethoxysilane [38]. Later, they reported another heterogeneous catalyst with bidentate phosphine rhodium complexes immobilized on γ-aminopropyltriethoxysilane modified MCM-41 (MCM-41-2P-RhCl3) (Fig. 7b) [39]. The catalyst effectively catalyzes the hydrosilylation reaction of olefin and triethoxysilane. The catalyst can be recovered by simple filtration. Compared with MCM-41-supported mercapto or thioether rhodium complexes, MCM-41-2P-RhCl3 catalyst showed higher activity and better reusability.

Matsuoka et al. immobilized cyclopentadienyl ruthenium(Ⅱ) complex on the surface of aminopropyl-modified MCM-41 (MCM-41-NHCOCpRu+Bz) (Fig. 8) [40]. The catalyst catalyzed the hydrosilylation of 1-hexyne with triethylsilane to vinylsilanes in acetonitrile under UV-light irradiation with high α-selectivity. After recycling, the catalytic activity of the catalyst did not lose significantly. The reaction proceeds through in situ generations of the corresponding acetonitrile complex as catalytically active species via ligand exchange reaction. Recently, they reported another catalyst with organoruthenium complex supported on MCM-41. Compared with the same kind of catalyst without carbonization treatment on the surface for hydrosilylation reaction of 1-hexyne and triethylsilane, the catalyst can improve the ratio of α-vinylsilane produced [41].

SBA-15 is another common and highly stable mesoporous silica sieve. Tu et al. reported a new type of heterogeneous catalyst by immobilization of platinum-bearing naphthalenolimine and 1,5-cyclooctadiene on the surface of SBA-15 (SBA-15-Naphth-Pt(COD)) (Fig. 9) [42]. The binary ligands also enabled the platinum atoms to form nanoclusters (ca. 1 nm), leading to high platinum loading of 8.69 wt%, which is higher than most immobilization platinum catalysts. The catalyst showed excellent catalytic activity and regioselectivity for the hydrosilylation of terminal olefins with trimethoxysilane. However, the recyclability of this catalyst is poor.

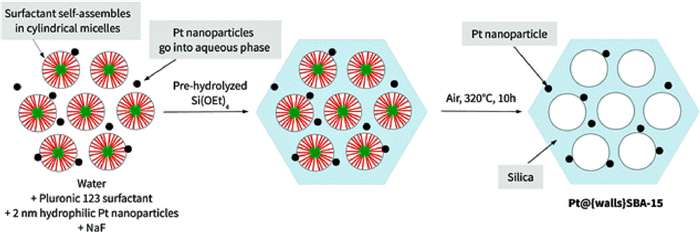

In 2017, Meille et al. reported a catalyst Pt@{walls}SBA-15 with Pt nanoparticles in the walls of mesostructured silica (Fig. 10) [43]. This catalyst showed high activity for the hydrosilylation of polymethylhydrosiloxane with 1-octene reaching TONs of ca. 105 without Pt leaching in the reaction. The absence of leaching was attributed to the physical trapping of the Pt NPs in the silica matrix. At the same time, the reactants are close to the active center via the microporosity of the support. The good performance indicates that this catalyst could be used in the pharmaceutical industry.

Kónya et al. reported platinum catalysts supported by SBA-15 with a size between 1.6 mm and 7.0 nm. The catalyst with 7.0 nm platinum nanoparticles was about 10 times higher than that with 1.6 nm for hydrosilylation reaction of phenylacetylene and triethylsilane. The increase in the size of the nanoparticles increases the yield of vinyl silane products and reduces the by-products [44].

Recently, Shu et al. reported a bifunctional heterogeneous catalyst Ptδ+/SBA-APTE-SA via post-synthesis modification of (3-aminopropyl)triethoxysilane (APTE), succinic anhydride (SA) and platinum precursors (Fig. 11) [45]. This Ptδ+/SBA-APTE-SA catalyst has a partial valence electron structure and a high degree of dispersion of the Pt species as a catalytic active site for alkenes hydrosilylation. This catalyst is highly stable and shows excellent reusability, maintaining 82% activity after five cycles.

The immobilization of homogeneous catalysts on magnetically recoverable solid supports is a powerful tool for collecting catalyst from the reaction mixture. This process will eliminate conventional separation techniques for catalyst recoveries, such as filtration or centrifugation.

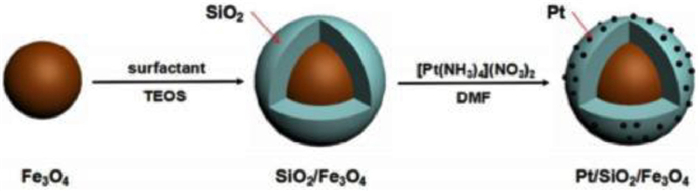

Li et al. took Fe3O4 nanoparticles as the core and coated the silica shell by the inverse microemulsion method to form superparamagnetic SiO2/Fe3O4 nanoparticles (Fig. 12). Ultrasmall Pt NPs were prepared through the induced nucleation, possibly by hydrophilic hydroxyl groups on the surface of the silica shell, to form Pt/SiO2/Fe3O4 NPs [46]. The synthesized catalyst has high catalytic activity for the hydrosilylation reaction of allyl polyether with low-hydrogen silicone oil. The catalyst dispersed in the reaction solution exhibits a superparamagnetic response under the action of a magnetic field and can be recycled seven times without significant loss of catalytic activity.

Fang et al. immobilized 3-aminopropyltriethoxysilane on the surface of Fe3O4@SiO2 followed by a reaction with chloroplatinic acid, giving a solid-supported Pt catalyst [47]. This catalyst exhibits excellent catalytic performance in the hydrosilylation of olefins with triethoxysilane. The magnet could recover the catalyst quickly and reuse it for several runs without significant catalytic activity and selectivity loss.

Li et al. synthesized another superparamagnetic Fe3O4-SiO2 core-shell nanoparticles supported heterogeneous platinum catalyst [48]. The SiO2 shell layer is modified by a vinyl-containing silane to fix platinum on the surface. This catalyst exhibited high activity in the hydrosilylation reaction of allyl-terminated polyether with polymethylhydrogensiloxane.

In 2019, heterogeneous platinum nanocatalysts through platinum immobilized on magnetic silica gel through boric acid, nitric acid, carboxylic acid, or sulfuric acid ligands were reported by Bao and co-workers [49]. Fe3O4@SiO2-BA@Pt shows the best catalytic activity and selectivity for hydrosilylation of various alkenes and alkynes with methyldichlorosilane or triethoxysilane. The activity is even better than Speier's catalyst. Fe3O4@SiO2-BA@Pt showed outstanding stability under reaction conditions. They also prepared platinum catalysts immobilized on superparamagnetic silica through a multi-carboxyl linker for hydrosilylation of alkenes with methyldichlorosilane [50]. These platinum nanoparticle catalysts exhibit unusual activity and selectivity.

Recently, Feng et al. used Fe3O4/SiO2 solid support which was modified with aminopropyltriethoxysilane and bis(imidazole)aldehyde to react with PtCl2 through coordination reaction, leading a magnetically separable heterogeneous catalyst Fe3O4@SiO2-biIMI-PtCl2 [51]. This catalyst can catalyze the hydrosilylation reaction between alkenes and silanes with mainly β-addition products.

Maciejewski et al. prepared a new type of ion-loaded liquid phase material using magnesium oxide-silica and magnesium oxide-silica/lignin as carriers. The homogeneous rhodium and platinum complexes were immobilized in these new supports to generate active hydrosilylation catalysts [52]. These catalysts showed good activity for 1-octene hydrosilylation with 1,1,1,3,5,5,5-heptamethyltrisiloxane, and it can be reused for several runs.

In 2019, Nakajima et al. used [PtMe2(μ-SMe2)]2 as Pt precursor and loaded on BPy PMO carrier to synthesize [PtMe2 (bpy PMO)] (Fig. 13) [53]. This catalyst is used for the hydrosilylation of phenylacetylene and trimethoxysilane. The reaction has the same catalytic activity as the homogeneous catalyst. The main products are β-vinyl silane in trans configuration. After 5 cycles of catalyst, the yield slightly decreased, but the selectivity remained unchanged. The catalyst after 5 cycles was characterized, and the mesoporous structure of the catalyst remained and no aggregation of Pt complex was found.

Graphite oxide (GO) is an inexpensive and stable material [54]. The carbons or at the edges of the layer always have various oxygen-containing functional groups, indicating that they can be modified with compounds containing active groups. Therefore, graphite oxide is an ideal supporting material for homogenous catalyst immobilization.

In 2013, Zhang et al. immobilized vinyltriethoxysilane on graphite oxide and reacted with chloroplatinic acid to synthesize a graphite oxide-supported heterogeneous Karstedt catalyst (Fig. 14). The catalyst has a good activity for the hydrosilylation of olefins and triethoxysilane with good recyclability. No noticeable loss of activity and selectivity was found after being reused seven times [55].

Gupton et al. combined the strong electrostatic adsorption technology and microwave radiography to prepare graphene-supported platinum catalyst, which shows excellent catalytic activity and stability for hydrosilylation reactions of olefins (TOF 4.8 × 106 h−1, TON = 9.4 × 106) [56]. The catalyst also exhibited good functional group tolerance with a broad range of substrate scope with minimal metal leaching (Scheme 3). Moreover, The packed bed platform for continuous hydrosilylation reactions is also successfully performed.

Li et al. developed an ammonium carbonate-assisted one-pot pyrolysis of EDTA-Pt complex to afford high-density isolated platinum single-atom sites, which are restricted to nitrogen-doped graphene with a platinum content of 5.3% by weight (Pt-ISA/NG) [57]. Characterization shows that Pt species are atomically dispersed on graphene support and stabilized by nitrogen in Pt–N4 structure. The catalyst shows high selectivity, reactivity, and recyclability for the anti-Markovnikov hydrosilylation of various terminal olefins with industrially relevant tertiary silanes under mild conditions (Scheme 4). The catalytic efficiency of the catalyst is four times higher than that of a 5 wt% commercial Pt/C catalyst. Pt-ISA/NG catalyst is stable under air, and the substrate scope is broad. Therefore, this Pt-ISA/NG is a promising catalyst for the synthesis of commercially relevant silicone.

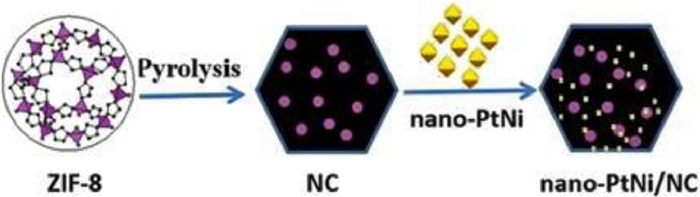

Later, they successfully prepared nano-PtNi particles on nitrogen-doped carbon (NC) through carbonization of ZIF-8 at different temperatures (Fig. 15) [58]. For the hydrosilylation of 1-octene with (EtO)3SiH, the catalyst prepared at 1000 ℃ (nano-PtNi/NC-1000) exhibited higher anti-Markovnikov selectivity (> 99%) than the catalyst obtained with lower temperatures. Notably, this nano-PtNi/NC-1000 catalyst showed good reusability for the hydrosilylation reaction. The morphology and distribution of PtNi particles in nano-PtNi/NC-1000 catalyst almost remained after use.

In 2020, Mata et al. immobilized platinum complexes with heterocyclic carbene ligands onto the surface of reduced graphene oxide (rGO) (Fig. 16) [59]. This hybrid material composed of a platinum complex and a graphene derivative was prepared in a single-step process under mild reaction conditions. The platinum sites were homogeneously distributed at the edges of defects. The alkyne hydrosilylation activity of the immobilized platinum catalyst is maintained, and the reaction rate is even greater than platinum complexes. The support plays an important role and may bring the close of substrates with the platinum sites at the graphene surface.

A PtFe3 intermetallic catalyst anchored on N-doped carbon spheres (PtFe3/CN) via an in-situ location-restricted migration (LRM) strategy was developed by Huang and co-workers recently [60]. The electron-rich nature of Pt sites could be attributed to the low electronegativity of iron atoms' coordination. This PtFe3/CN catalyst gave better activity for the alkene hydrosilylation with high selectivity for anti-Markovnikov addition than traditional single-atom Pt catalyst loading on N-doped graphene carbon and Pt nanoparticles supported on N-doped carbon spheres (Scheme 5). The turnover number (TON) of alkene hydrosilylation can reach 740,000, and no platinum leaching occurs. Lvarez et al. synthesized graphene−NHC−rhodium hybrid catalysts from thermally reduced graphene oxides [61]. The 3-methyl-4-phenyl-1,2,3-triazole salt was used to modify the reduced graphene oxides leading to hydroxyl-triazolium-functionalized materials. The final obtained rhodium hybrid materials contain either alkoxo or triazolylidene molecular rhodium(Ⅰ) complexes depending on the protection of the hydroxyl groups. Catalyst characterization disclosed the coordination sphere of the supported rhodium(Ⅰ) complexes in rhodium hybrid materials (Fig. 17). This graphene oxide-supported rhodium catalyst exhibits excellent activity for the hydrosilylation of terminal and internal alkynes. Moreover, these supported rhodium catalysts showed good selectivity to β-(Z) vinylsilane isomers (terminal substrates) or syn-additions (internal substrates).

Carbon nanotubes (CNTs) are carbon materials that could be used as support for heterogeneous catalysis preparation. Doris and co-workers reported a heterogeneous platinum-based catalyst based on a carbon nanotube platform [62]. The obtained catalyst (0.04 mol% catalyst loading) showed excellent activity for the solvent-free hydrosilylation of alkenes and alkynes at room temperature. The substrate scope is broad, including complex molecules bearing sensitive groups, and its recycling ability is good (Fig. 18).

Atomically dispersed Au anchored on g-C3N4 nanosheets is developed by Chen et al. [63]. The atomic Au species are in the +1 oxidative state, coordinating with three nitrogen atoms via X-ray absorption fine structure (XAFS) characterization. Gold sites' unique structural and electronic characteristics are crucial for the activation of Si–H bonds. Aromatic alkynes and aliphatic alkynes can effectively produce corresponding β-(E)-vinylsilane products with high yields and functional group tolerance (Scheme 6). This Au catalyst could be reused at least five times without obvious loss in activity and selectivity.

Metal oxides are ideal supports for the preparation of the catalyst and have been widely applied in industrial production. The commonly used metal oxide carriers mainly include alumina oxide, magnesium oxide, cerium oxide, titanium oxide, etc. Most of the metal oxide supported catalysts for alkene and alkyne hydrosilylation are based on palladium, rhodium, and platinum.

Catalysts prepared through the sol-gel method have been well developed, and these catalysts generally show good catalytic activity for various organic reactions. In 2000, Cervantes and co-workers reported catalysts based on Pt and Ru supported on inorganic matrices MgO through the sol-gel process. These Ru–MgO and Pt–MgO catalysts are able to catalyze hydrosilylation of phenylacetylene with Ph3SiH, Ph2MeSiH, and PhMe2SiH, leading to a specific activity and good selectivity (Fig. 19) [64].

In 2005, Caporusso et al. developed supported gold nanoparticles using the metal vapour synthesis (MVS) technique [65]. The catalysts were prepared by depositing acetone solvated Au atoms on different supports, such as γ-Al2O3 and carbon. These catalysts are very efficient for the hydrosilylation of 1-hexyne with different silanes. Almost 100% selectivity towards the β-(E) isomer was obtained (Scheme 7). These merits make these gold-based catalysts a good alternative to more expensive Pt-based catalysts for the alkyne hydrosilylations through this heterogeneous synthetic process.

Corma et al. reported that CeO2 nanoparticles could stabilize cationic forms of gold (AuⅠ and AuⅢ) [66] in 2002. Later, they found that this gold supported on CeO2 catalyst can catalyze the hydrosilylation of aldehydes, ketones, olefins, imines, and alkynes with excellent selectivity [67]. This catalyst can be recycled successfully without any loss of activity. Mechanism studies disclosed that the presence of stabilized AuⅢ on the surface Au/CeO2 is crucial for these hydrosilylation reactions.

In 2012, a catalyst of gold nanoparticles supported on titanium oxide (0.8-1.4 mol%) catalyst was reported by Stratakis et al. This catalyst can catalyze the β-(E) regioselective hydrosilylation of various functionalized terminal alkynes with alkylhydrosilanes with excellent yields (Scheme 8) [68]. The less hindered triethylsilane and dimethylphenylsilane react faster (2-4 h) than the bulky triphenylsilane. Internal alkynes are less reactive or even unreactive under this catalytic system. Mechanism studies disclosed that the TiO2 stabilized cationic AuⅠ species are the reactive sites, including a AuⅠ-AuⅢ redox catalytic cycle (Fig. 20).

PtO2 is a highly active and regioselective hydrosilylation catalyst for hydrosilylation [69]. Initially, Pt(Ⅳ) is reduced to Pt(Ⅱ) or Pt(0) to generate the active sites, which are soluble in the reaction mixture and could be removed from the product after the reaction. However, only a small amount of Pt sites (≪ 10 ppm) are needed [70].

The development of low Pt loading and stable catalyst is desired considering the price of the Pt. In 2010, Yus et al. demonstrated a Pt/TiO2 catalyst that can catalyze the hydrosilylation of terminal and internal alkynes, bearing different functional groups with three hydrosilanes to give the corresponding alkenylsilanes in high yields under solventless conditions [71]. This catalytic system proceeded with exclusive syn addition of hydrosilanes to the C≡C bond, and the β/α regioselectivity can reach up to 94:6. In contrast to known heterogeneous platinum catalysts, the present Pt/TiO2 catalyst could catalyze the reaction under air and mild conditions (Scheme 9). Moreover, this catalyst can be easily recovered from the reaction mixture and reused in several cycles without activity loss.

In 2017, Beller and co-workers reported the first heterogeneous single-atom Pt catalyst by decorating alumina nanorods with platinum atoms. This single-atom based heterogeneous platinum catalyst was a selective catalyst for alkene hydrosilylation with high TON (~105) [72]. Compared to the known heterogenized catalysts, this Pt/NR-Al2O3-IP catalyst gives high activity and excellent chemoselectivity (Scheme 10). The substrates with sensitive reducible and functional groups are also compatible. Moreover, industrially relevant polysilane PL6020 was tested with 1-octene or vinyl-trimethylsilane (Scheme 11). These reactions proceeded smoothly catalyzed by this single-atom Pt catalyst.

In 2018, Miura et al. synthesized 1Pd5Au/Al2O3 by doping Pd atoms into Au NP and loading on alumina support [73]. The synthesized catalyst is used for the hydrosilylation of diene with silane, and the main product is internal alkenylsilane with E configuration (Scheme 12). The catalyst can still maintain high activity after three cycles. Kinetic experiments showed that the incorporation of Pd atoms into Au NP promoted the coupling of C-H, the rate-limiting step of the reaction, and increased the reaction rate.

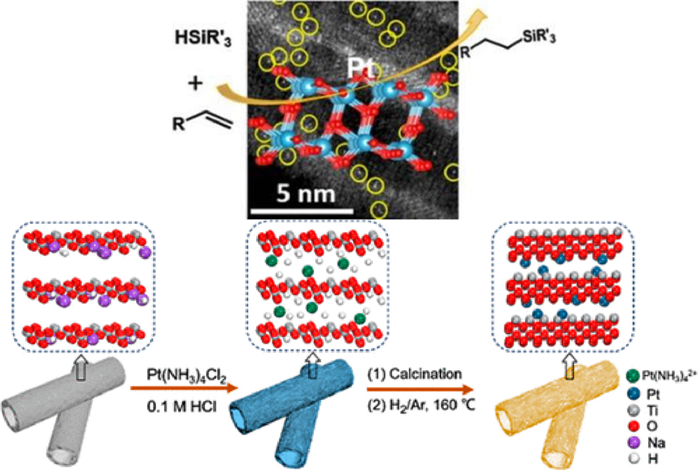

Li et al. developed a new catalyst with single atomic partially charged Pt sites on anatase TiO2 (Pt1δ+/TiO2) via electrostatic-induction ion exchange and two-dimensional confinement strategy (Fig. 21) [74]. This catalyst can realize the anti-Markovnikov alkene hydrosilylation with high activity, selectivity, and excellent reusability. The good performance of this catalyst is attributed to the partially positive valence electronic structure and atomic dispersion of Pt sites. The strategy can reduce the consumption of precious platinum in the form of single-atom Pt and has the potential application in the hydrosilylation industry.

In 2019, Tait et al. reported a metal-ligand self-assembly process to create Pt single-sites on high surface area supports MgO, Al2O3, and CeO2 [75]. One-step impregnating Pt and 3,6-di-2-pyridyl-1,2,4,5-tetrazine (DPTZ) simultaneously can generate Pt-DPTZ single-sites on supports. A highly uniform structure, with 90% Pt as single-sites, was obtained on MgO. Pt(Ⅱ) centers could be stabilized in the DPTZ binding pockets. Strong, non-competitive support-ligand interaction favors the formation of Pt single-sites. However, the catalysts prepared via two-step impregnation of Pt and DPTZ are less effective because Pt atoms have low mobility and accessibility on supports. The single-sites Pt-DPTZ/MgO catalyst was effective for 1-octene hydrosilylation with dimethoxymethylsilane in 96% yield (Scheme 13). Compared with commercial homogeneous catalysts, Pt-DPTZ/MgO catalyst has better activity and selectivity without the formation of colloidal platinum.

To improve catalyst's recyclability of previous Pt-DPTZ SACs, they reported a series of bidentate N-based ligand-coordinated supported Pt hydrosilylation catalysts [76]. First, they prepared catalyst Pt-PDO/CeO2 (PDO = 1,10-phenanthroline-5,6-dione) by replacing DPTZ with a ligand PDO containing additional functional groups. This catalyst can proceed for four reaction cycles, and much less Pt leaching occurs. A Pt(2+δ)+ species converted from Pt2+ is likely the active site. Second, mixing DPTZ with BPhen leads to a highly reusable catalyst Pt-BPhen+DPTZ/CeO2 which shows only 10% activity decrease after three cycles. The ligand mixing provides additional van der Waals interaction with the support.

They also studied the impact of the defect density of the TiO2 on Pt SACs with ligand DPTZ for hydrosilylation reactions [77]. These Pt species are stabilized by bonding with DPTZ, surface oxygen, and residual chloride from the metal precursor. The activity of catalysts is positively correlated with the defect density of the TiO2 (Fig. 22). The turnover number is 12530 for Pt SACs on a defective surface, which is significantly higher than Pt SACs on a pristine TiO2 surface under the same reaction conditions. The coordination of Pt with more chloride than on pristine titania surfaces will shorten the induction period of the reaction. Besides, the high dispersion of Pt–DPTZ units on defective regions of titania surfaces allows facile contact between Pt sites and reactants. These Pt–DPTZ SACs show high stability through multiple cycles of reactions. Therefore, optimizing the metal–support interaction through the oxide support defect engineering approach can also be applied to other oxide surfaces.

Besides the Pt single-site catalyst, Prieto et al. developed a catalyst through a one-pot combination of single-atom Rh and Ru on CeO2 [78]. Individually, Ru/CeO2 and Rh/CeO2 catalysts show specificity for olefin double-bond migration and anti-Markovnikov α-olefin hydrosilylation, respectively (Fig. 23). The combination of two single-atom metal catalysts can realize a selective olefin isomerization-hydrosilylation tandem process with high regio-selectivity (> 95%), including terminal and internal olefins. The catalyst recycling and reuse ability are also good, while no noticeable decrease in either activity or selectivity after five consecutive tandem reaction cycles. DFT calculations ascribe the selectivity to the differences in the binding strength of the olefin substrate to the metal centers. This strategy provides a new method of single-atom metal catalysts in tandem catalysis, which can be a bridge between homogeneous and heterogeneous catalysis.

Very recently, Su and co-workers reported a 0.5Ruδ+/ZrO2 catalyst with partially charged single-atom Ru supported on ZrO2 by the simple impregnation method followed by reduction [79]. This 0.5Ruδ+/ZrO2 catalyst showed excellent catalytic performance for ethylene hydrosilylation with triethoxysilane to ethyltriethoxysilane. Notably, poor catalytic performance was obtained using other metal oxides as support, including 0.5Ru/CeO2, 0.5Ru/Al2O3, and 0.5Ru/SiO2. Structural characterizations and density functional theory calculations reveal that the atomic dispersion of the active Ru species and their unique electronic properties are crucial to realize the high activity for hydrosilylation.

Except for the precious metal, non-noble metal based heterogeneous catalyst was also developed for alkene hydrosilylation. In 2012, Kaneda et al. reported an air-stable cobalt ion-doped titanium oxide catalyst by hydrogen treatment method for alkene hydrosilylation under solvent-free conditions [80]. The reported Co/TiO2 catalyst was a highly efficient catalyst for the anti-Markovnikov hydrosilylation of alkenes with broad functional group tolerance (Scheme 14). This catalyst showed high reusability without activity loss after five runs. The detailed investigation of the relationship between the active site and catalytic performance disclosed that the high stability and durability of Co/TiO2 originated from the strong interaction between Co and TiO2 through the formation of CoTiO3 solid solution species.

Obora and co-workers prepared DMF-protected monodisperse α-Fe2O3 NPs (2–5 nm) from Iron(Ⅲ) acethylacetonate [81]. Characterization disclosed that DMF molecules existed as a tightly protective layer around the Fe2O3 NPs. The synthesized Fe2O3 NPs showed good catalytic activity for hydrosilylation of alkenes under additives-free conditions (Scheme 15). No significant deactivation of this DMF-protected Fe2O3 NPs was observed after the 5th run, while the separation and recovery of the Fe2O3 NPs from the reaction mixture was simple.

Cross-linked polymers are always used as scaffolds for catalyst preparation. For example, polystyrene is one of the most popular polymers supports because of its facile functionalization and chemical inertness. In 2002, Kan et al. prepared a cross-linked polystyrene-platinum complex that can catalyze the hydrosilylation of olefins with dichloromethylsilane and diethoxymethylsilane. This catalyst has no catalytic activity for olefins containing two substituents on the double bond [82]. Kowalewska reported a new polymeric support based on tris(dimethylvinyl)methyl substituted polystyrene, which has coordination-active sites (–CH=CH2 moieties) (Fig. 24). This polymer-bound platinum complex shows good activity in hydrosilylation of vinylsilanes, which is comparable to the Karstedt's catalyst [83].

Lai et al. developed a copolymer of styrene, 2-vinylpyridine, and allyl polyethylene glycol as a cross-linking agent. The copolymer-immobilized platinum showed good activity for hydrosilylation of 3,3,3-trifluoropropene with triethoxysilane [84]. The presence of 2-vinylpyridine and allyl polyethylene glycol in the polymer was crucial to improve the activity (Fig. 25).

They also reported another platinum nanoparticle catalyst stabilized by 4-aminobenzoic acid with functionalized polyethylene glycol (Scheme 16) [85]. These functionalized PEG-stabilized Pt nanoparticles form a very efficient catalyst for alkenes hydrosilylation. The Pt nanoparticles can be fully immobilized in the PEG-AMB and recycled at least nine times without any obvious loss of catalytic activity.

In 2014, a catalyst of palladium nanoparticles stabilized with tris-imidazolium tetrafluoroborates was reported by Pleixats and co-workers [86]. This catalyst can catalyze the stereoselective hydrosilylation of internal alkynes to give (E)-vinylsilanes in excellent yields. Then they developed other rhodium nanoparticles with controllable morphology and size, which were stabilized by nitrogen-rich polyoxyethylene derivatives [87]. These nanomaterials were prepared via the reduction of rhodium(Ⅲ) chloride trihydrate with NaBH4 in water at room temperature (Fig. 26). The flower-like Rh NPs were effective for the stereoselective hydrosilylation of internal alkynes to form (E)-vinylsilanes in excellent yields under solvent-free conditions. Specifically, the presence of water leads to the transfer hydrogenation products when using the Pd catalyst. This rhodium nanoparticle catalyst has good recyclability and is insensitive to the presence of water.

Porous organic polymers (POPs) have the character of high surface areas, good stabilities, and tunable pore size distribution. These insoluble porous polymers with catalytic sites adopted onto their framework can enhance the performance in catalysis. A Co(acac)2/POL-PPh3 catalyst was developed by Zhan and co-workers to catalyze (E)-selective hydrosilylation of alkynes with PhSiH3 for the synthesis of (E)-β-vinylsilanes with high regio- and stereoselectivity [88]. This polymer-based cobalt catalyst could be recycled several times in a continuous flow system without loss of activity and selectivity. The heterogeneous earth-abundant cobalt catalyst for hydrosilylation shows potential industrial application.

In 2020, they developed another conjugated microporous polymer with pyridine units containing adjacent C≡C bonds. The resulting parts-per-million (ppm) levels catalyst (Pd–CMP-1) was a highly efficient catalyst for regioselective allene hydrosilylation to produce branched allylsilanes (Scheme 17) [89]. The catalyst was compatible with aliphatic allenes bearing various functional and reactive groups. The confinement effect of the porous structure of the polymer was beneficial for regioselectivity control.

Using trace amounts (< 1 ppm) of metal catalysts in organic synthesis is rare and shows potential for industry application. Very recently, Zhan and co-workers designed and synthesized a single-atom Pd-based porous organic ligand polymer Pd1@POL [90]. This catalyst can realize the hydrosilylation of allenes with 0.98 ppm Pd loading with regioselectivity > 100:1 (Scheme 18). This low Pd loading catalyst showed super catalytic efficiency for hydrosilylation of allene with turnover number up to 772,358, which was 200 times higher than previously reported. This catalyst could be recycled numerous times in a continuous flow system without any loss in activity and selectivity.

Metal-organic frameworks (MOFs) are prepared from organic ligands and metal nodes. They exhibit unique properties in many areas, including application in heterogeneous catalysis [91], such as degradation of organic pollutants [92], CO2 utilization [93], hydrogenation reactions [94], oxidations [95].

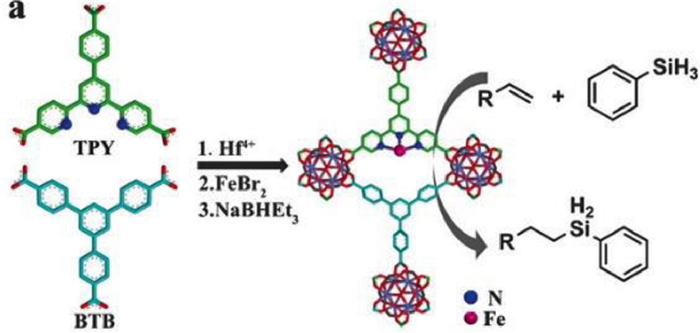

MOFs based materials were also developed for the silylations of unsaturated bonds. In 2016, Lin et al. synthesized a new two-dimensional material MOLs using [Hf6(μ3-O)4(μ3-OH)4(carboxylate)12] and benzene-1,3,5-tribenzoate (BTB). Uniform MOLs with monolayer thickness can be obtained using a reactant molar ratio of HfCl4/BTB/HCO2H/H2O/DMF = 1.5:1:830:290:2280 by heating the mixture at 120 ℃ for 48 h. Then the doping with 4′-(4-benzoate)-(2,2′,2′-terpyridine)-5,5′′-dicarboxylate (TPY) to coordinate with the iron center can lead to the MOL catalyst Fe-TPY-MOL (Fig. 27) [96]. Pure anti-Markovnikov product in 100% yield was obtained with 0.02% Fe-TPY-MOL for the hydrosilylation of styrene with PhSiH3 (TON > 5000) (Scheme 19). Notably, no product was observed for the MOF with an interlocked 3D structure. The MOL-immobilized Fe-TPY species are true molecular catalysts by preventing bimolecular disproportionation.

Later, they report another example of a porous Zr-MOF based on a triarylphosphine-derived tricarboxylate linker. Single-site mono(phosphine)-Rh or Ir catalysts were obtained after metalation [97]. These catalysts show superior activity for the hydrosilylation of alkenes than a corresponding homogeneous catalyst (Scheme 20). For example, hydrosilylation of 1-octene with triethylsilane catalyzed by 0.0001 mol% catalyst at room temperature for 72 h can give the product in 82% yield (TON = 820,000). The MOF catalysts can also be reused multiple times without any loss of catalytic activity.

In 2019, Hu et al. developed a new nickel carboxylate MOFs, which can be easily prepared by mixing a nickel salt with dicarboxylic acid or polycarboxylic acid ligands [98]. These Ni MOF catalysts show excellent activity for anti-Markovnikov hydrosilylation of alkenes with turnover numbers up to 9500. The best catalyst can be reused for ten recycling runs without obvious activity loss. The substrate scope under this catalytic system is broad, with an excellent functional group tolerance (Scheme 21). Very recently, Peng and co-workers reported a Co-MOF for hydrosilylation of styrene or its derivatives with Ph2SiH2 in the presence of NaBHEt3 [99]. A variety of linear alkenes and aromatic olefins can be converted to linear alkylsilanes with excellent activity and selectivity.

The hydrosilylation of multiple-functional alkenes with silanes can lead to a product with one or more functional groups for further transformation, especially substrates with two double bonds. However, the most popular Karstedt's catalyst usually leads to unisolable mixtures without good selectivity. Therefore, high site selectivity for hydrosilylation with a broad scope of substrates is still desired in industry production. Liu and co-workers reported a cage-trapped Pt catalyst (COP1-T-Pt) that exhibited very high activity and interesting size-selectivity for important alkoxysilanes synthesis from alkene hydrosilylations (Scheme 22) [100]. Due to the confined environment of cage-trapped Pt catalyst, it exhibited remarkable size selectivity and high site selectivity for alkenes with multiple functional groups. For example, only the allyl addition product was obtained for substrate allyl methacrylate due to the less steric hindrance, and no methacrylate addition product was detected.

We summarized the recent development of heterogeneous catalysts for unsaturated C-C bond hydrosilylations, including alkene, alkyne, and allene (Table 1). The progress in this area is of great interest for both academic and industrial investigations in that the silicone industry always desires new improvements in catalysis and technology. The present review discusses the heterogeneous hydrosilylation catalysts based on the following support: silicon, molecular sieve, carbon material, metal oxide, organic polymer, and MOFs material. The metal immobilization on these supports can form supported metal complexes, nanoparticles, or single-atom catalysts. Most of these catalysts show high hydrosilylation activities and selectivities with good recycling properties. For most case, terminal alkene and alkyne show high activity under the heterogeneous catalytic systems.

However, the comprehensive understanding of the original relationship between structural and the regio- and stereoselectivity is still urgent because this is important for the catalysts' rational design for further development.

Nevertheless, most of the reported heterogeneous catalysts are based on noble metals (Pt, Rh, Pd, Ru), although inexpensive non-noble metal based homogeneous catalysis has been well developed. The use of non-noble metals such as Fe, Ni, and Co for heterogeneous catalyst exploration, especially for industrial production, is still desired but challenging.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

We are grateful for the financial support from the National Natural Science Foundation of China (No. 22001227), the Natural Science Foundation of Jiangsu Province (No. BK20200919), the "Jiangsu Specially-Appointed Professor Plan", and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Supplementary material associated with this article can be found, in the online version, at doi:

B. Marciniec, Hydrosilylation: A Comprehensive Review on Recent Advances, Springer Science, 2009.

E. Rémond, C. Martin, J. Martinez, F. Cavelier, Chem. Rev. 116 (2016) 11654–11684.

doi: 10.1021/acs.chemrev.6b00122

R. Ramesh, D.S. Reddy, J. Med. Chem. 61 (2018) 3779–3798.

doi: 10.1021/acs.jmedchem.7b00718

L. Li, Y.L. Wei, L.W. Xu, Synlett 31 (2020) 21–34.

doi: 10.1055/s-0039-1691496

F. Ye, Z. Xu, L.W. Xu, Acc. Chem. Res. 54 (2021) 452–470.

doi: 10.1021/acs.accounts.0c00740

F. Ye, L.W. Xu, Synlett 32 (2021) 1281–1288.

doi: 10.1055/a-1408-6795

L.X.W. Huang, Chin. J. Org. Chem. 41 (2021) 4515–4516.

doi: 10.6023/cjoc202100080

H. Wang, X. Zhang, Y. Li, L.W. Xu, Angew. Chem. Int. Ed. 61 (2022) e202210851.

doi: 10.1002/anie.202210851

X. Zhang, J. Fang, C. Cai, G. Lu, Chin. Chem. Lett. 32 (2021) 1280–1292.

doi: 10.1016/j.cclet.2020.09.058

L.H. Sommer, E.W. Pietrusza, F.C. Whitmore, J. Am. Chem. Soc. 69 (1947) 188-188.

J.L. Speier, J.A. Webster, G.H. Barnes, J. Am. Chem. Soc. 79 (1957) 974–979.

doi: 10.1021/ja01561a054

B. Karstedt, Patent: US3775452A, 1973.

L.D. de Almeida, H. Wang, K. Junge, X. Cui, M. Beller, Angew. Chem. Int. Ed. 60 (2021) 550–565.

doi: 10.1002/anie.202008729

P.F. Fu, L. Brard, Y. Li, T.J. Marks, J. Am. Chem. Soc. 117 (1995) 7157–7168.

doi: 10.1021/ja00132a015

K. Takaki, K. Sonoda, T. Kousaka, et al., Tetrahedron Lett. 42 (2001) 9211–9214.

doi: 10.1016/S0040-4039(01)02027-5

J. Li, C. Zhao, J. Liu, et al., Inorg. Chem. 55 (2016) 9105–9111.

doi: 10.1021/acs.inorgchem.6b01670

D.S. Levine, T.D. Tilley, R.A. Andersen, Chem. Commun. 53 (2017) 11881–11884.

doi: 10.1039/C7CC06417A

J. Liu, W. Chen, J. Li, C. Cui, ACS Catal. 8 (2018) 2230–2235.

doi: 10.1021/acscatal.8b00010

X. Liu, Q. Wen, L. Xiang, X. Leng, Y. Chen, Chem. Eur. J. 26 (2020) 5494–5499.

doi: 10.1002/chem.202000342

W. Chen, H. Song, J. Li, C. Cui, Angew. Chem. Int. Ed. 59 (2020) 2365–2369.

doi: 10.1002/anie.201913773

W. Chen, C. Jiang, J. Zhang, et al., J. Am. Chem. Soc. 143 (2021) 12913–12918.

doi: 10.1021/jacs.1c04689

S. Zhu, W. Xu, D. Hong, et al., Inorg. Chem. 62 (2023) 381–391.

doi: 10.1021/acs.inorgchem.2c03488

Q.J. Miao, Z.P. Fang, G.P. Cai, Catal. Commun. 4 (2003) 637–639.

doi: 10.1016/j.catcom.2003.10.006

B. Marciniec, K. Szubert, M.J. Potrzebowski, I. Kownacki, K. Łȩszczak, Angew. Chem. Int. Ed. 47 (2008) 541–544.

doi: 10.1002/anie.200704362

B. Marciniec, K. Szubert, R. Fiedorow, et al., J. Mol. Catal. A: Chem. 310 (2009) 9–16.

doi: 10.1016/j.molcata.2009.05.013

B. Marciniec, K. Szubert, M.J. Potrzebowski, I. Kownacki, H. Maciejewski, ChemCatChem 1 (2009) 304–310.

doi: 10.1002/cctc.200900111

K. Motokura, K. Maeda, W.J. Chun, ACS Catal. 7 (2017) 4637–4641.

doi: 10.1021/acscatal.7b01523

K. Maeda, Y. Uemura, M. Kim, et al., J. Phy. Chem. C 123 (2019) 14556–14563.

doi: 10.1021/acs.jpcc.9b03280

K. Usui, K. Miyashita, K. Maeda, et al., Org. Lett. 21 (2019) 9372–9376.

doi: 10.1021/acs.orglett.9b03602

K. Usui, Y. Manaka, W.J. Chun, K. Motokura, Chem. Eur. J. 28 (2022) e202104001.

doi: 10.1002/chem.202104001

J. Li, C. Yang, L. Zhang, T. Ma, J. Organomet. Chem. 696 (2011) 1845–1849.

doi: 10.1016/j.jorganchem.2011.02.021

F. Li, Y. Li, J. Mol. Catal. A: Chem. 420 (2016) 254–263.

doi: 10.1016/j.molcata.2016.04.019

D. Shao, Y. Li, RSC Adv. 8 (2018) 20379–20393.

doi: 10.1039/C8RA01828F

A.J. Chalk, J.F. Harrod, J. Am. Chem. Soc. 87 (1965) 16–21.

doi: 10.1021/ja01079a004

R. Ciriminna, V. Pandarus, G. Gingras, F. Béland, M. Pagliaro, ACS Sustain. Chem. Eng. 1 (2013) 249–253.

doi: 10.1021/sc3001096

V. Pandarus, R. Ciriminna, G. Gingras, et al., Green Chem. 21 (2019) 129–140.

doi: 10.1039/C8GC02569J

J.W. Zhang, G.P. Lu, C. Cai, Green Chem. 19 (2017) 2535–2540.

doi: 10.1039/C7GC00818J

R. Hu, L. Zha, M. Cai, Catal. Commun. 11 (2010) 563–566.

doi: 10.1016/j.catcom.2009.12.020

R. Hu, W. Hao, M. Cai, Chin. J. Chem. 29 (2011) 1629–1634.

doi: 10.1002/cjoc.201180292

D. Do Van, T. Hosokawa, M. Saito, Y. Horiuchi, M. Matsuoka, Appl. Catal. A: Gen. 503 (2015) 203–208.

doi: 10.1016/j.apcata.2015.05.039

D. Van Do, T. Hosokawa, Y. Horiuchi, M. Matsuoka, Res. Chem. Interm. 46 (2020) 5297–5306.

doi: 10.1007/s11164-020-04263-z

Y. Huo, J. Hu, S. Lin, et al., Appl. Organomet. Chem. 33 (2019) e4874.

doi: 10.1002/aoc.4874

T. Galeandro-Diamant, R. Sayah, M.L. Zanota, et al., Chem. Commun. 53 (2017) 2962–2965.

doi: 10.1039/C6CC10154B

D.G. Dobó, D. Sipos, A. Sápi, et al., Catalysts 8 (2018) 22.

doi: 10.3390/catal8010022

W. Chen, Z. Xie, H. Liang, et al., RSC Adv. 10 (2020) 3175–3183.

doi: 10.1039/C9RA09082G

H. Zai, Y. Zhao, S. Chen, et al., RSC Adv. 6 (2016) 98520–98527.

doi: 10.1039/C6RA16944A

J. Zhao, Y. Gui, Y. Liu, et al., Catal. Lett. 147 (2017) 1127–1132.

doi: 10.1007/s10562-017-1984-x

H. Zai, Y. Zhao, S. Chen, et al., Nano Res. 11 (2018) 2544–2552.

doi: 10.1007/s12274-017-1879-6

L. Li, Y. Li, A. Assefa, J.J. Bao, Transit. Metal Chem. 44 (2019) 779–787.

doi: 10.1007/s11243-019-00348-w

L. Li, Y. Li, J. Yan, et al., RSC Adv. 9 (2019) 12696–12709.

doi: 10.1039/C9RA00375D

Y. Huo, J. Hu, Y. Tu, et al., J. Organomet. Chem. 936 (2021) 121714.

doi: 10.1016/j.jorganchem.2021.121714

O. Bartlewicz, M. Zieliński, M. Kaczmarek, H. Maciejewski, Mol. Catal. 509 (2021) 111615.

doi: 10.1016/j.mcat.2021.111615

Y. Naganawa, Y. Maegawa, H. Guo, et al., Dalton Trans. 48 (2019) 5534–5540.

doi: 10.1039/C9DT00078J

Y. Zhu, S. Murali, W. Cai, et al., Adv. Mater. 22 (2010) 3906–3924.

doi: 10.1002/adma.201001068

F. Rao, S. Deng, C. Chen, N. Zhang, Catal. Commun. 46 (2014) 1–5.

doi: 10.1016/j.catcom.2013.10.043

C.J. Kong, S.E. Gilliland, B.R. Clark, B.F. Gupton, Chem. Commun. 54 (2018) 13343–13346.

doi: 10.1039/C8CC07641C

Y. Zhu, T. Cao, C. Cao, et al., ACS Catal. 8 (2018) 10004–10011.

doi: 10.1021/acscatal.8b02624

J. Wen, Y. Chen, S. Ji, et al., Nano Res. 12 (2019) 2584–2588.

doi: 10.1007/s12274-019-2490-9

A. Mollar-Cuni, P. Borja, S. Martin, G. Guisado-Barrios, J.A. Mata, Eur. J. Inorg. Chem. 2020 (2020) 4254–4262.

doi: 10.1002/ejic.202000356

Y. Han, Y. Xiong, C. Liu, et al., J. Catal. 396 (2021) 351–359.

doi: 10.1016/j.jcat.2021.03.004

B. Sánchez-Page, M.V. Jiménez, J.J. Pérez-Torrente, et al., ACS Appl. Nano Mater. 3 (2020) 1640–1655.

doi: 10.1021/acsanm.9b02398

D.V. Jawale, V. Geertsen, F. Miserque, et al., Green Chem. 23 (2021) 815–820.

doi: 10.1039/D0GC03943H

X. Feng, J. Guo, S. Wang, Q. Wu, Z. Chen, J. Mater. Chem. A 9 (2021) 17885–17892.

doi: 10.1039/D1TA05528C

R. Jiménez, J.M. López, J. Cervantes, Can. J. Chem. 78 (2000) 1491–1495.

doi: 10.1139/v00-086

A.M. Caporusso, L.A. Aronica, E. Schiavi, et al., J. Organomet. Chem. 690 (2005) 1063–1066.

doi: 10.1016/j.jorganchem.2004.10.051

S. Carrettin, P. Concepción, A. Corma, J.M. López Nieto, V.F. Puntes, Angew. Chem. Int. Ed. 43 (2004) 2538–2540.

doi: 10.1002/anie.200353570

A. Corma, C. Gonzalez-Arellano, M. Iglesias, F. Sanchez, Angew. Chem. Int. Ed. 46 (2007) 7820–7822.

doi: 10.1002/anie.200702032

A. Psyllaki, I.N. Lykakis, M. Stratakis, Tetrahedron 68 (2012) 8724–8731.

doi: 10.1016/j.tet.2012.08.021

N. Sabourault, G. Mignani, A. Wagner, C. Mioskowski, Org. Lett. 4 (2002) 2117–2119.

doi: 10.1021/ol025658r

S. Putzien, E. Louis, O. Nuyken, F.E. Kühn, Catal. Sci. Technol. 2 (2012) 725–729.

doi: 10.1039/C2CY00367H

F. Alonso, R. Buitrago, Y. Moglie, et al., J. Organomet. Chem. 696 (2011) 368–372.

doi: 10.1016/j.jorganchem.2010.09.068

X. Cui, K. Junge, X. Dai, et al., ACS Cent. Sci. 3 (2017) 580–585.

doi: 10.1021/acscentsci.7b00105

H. Miura, S. Sasaki, R. Ogawa, T. Shishido, Eur. J. Org. Chem. 2018 (2018) 1858–1862.

doi: 10.1002/ejoc.201800224

Y. Chen, S. Ji, W. Sun, et al., J. Am. Chem. Soc. 140 (2018) 7407–7410.

doi: 10.1021/jacs.8b03121

L. Chen, G.E. Sterbinsky, S.L. Tait, J. Catal. 365 (2018) 303–312.

doi: 10.1016/j.jcat.2018.07.004

L. Chen, I.S. Ali, S.L. Tait, ChemCatChem 12 (2020) 3576–3584.

doi: 10.1002/cctc.202000085

X. Zhou, L. Chen, G.E. Sterbinsky, et al., Catal. Sci. Technol. 10 (2020) 3353–3365.

doi: 10.1039/C9CY02594D

B.B. Sarma, J. Kim, J. Amsler, et al., Angew. Chem. Int. Ed. 59 (2020) 5806–5815.

doi: 10.1002/anie.201915255

M. Li, S. Zhao, J. Li, et al., Nano Res. 15 (2022) 5857–5864.

doi: 10.1007/s12274-022-4227-4

T. Mitsudome, S. Fujita, M. Sheng, et al., Green Chem. 21 (2019) 4566–4570.

doi: 10.1039/C9GC01981B

R. Azuma, S. Nakamichi, J. Kimura, et al., ChemCatChem 10 (2018) 2378–2382.

doi: 10.1002/cctc.201800161

C. Kan, X. Kong, C. Du, D. Liu, Polym. J. 34 (2002) 97–102.

doi: 10.1295/polymj.34.97

A. Kowalewska, J. Organomet. Chem. 693 (2008) 2193–2199.

doi: 10.1016/j.jorganchem.2008.03.021

Y. Bai, J. Peng, Y. Hu, J. Li, G. Lai, J. Fluorine Chem. 132 (2011) 123–127.

doi: 10.1016/j.jfluchem.2010.12.007

Y. Bai, S. Zhang, Y. Deng, et al., J. Colloid Interface Sci. 394 (2013) 428–433.

doi: 10.1016/j.jcis.2012.11.048

M. Planellas, W. Guo, F. Alonso, et al., Adv. Syn. Catal. 356 (2014) 179–188.

doi: 10.1002/adsc.201300641

W. Guo, R. Pleixats, A. Shafir, T. Parella, Adv. Syn. Catal. 357 (2015) 89–99.

doi: 10.1002/adsc.201400740

R.H. Li, X.M. An, Y. Yang, et al., Org. Lett. 20 (2018) 5023–5026.

doi: 10.1021/acs.orglett.8b02176

Y.N. Jiang, J.H. Zeng, Y. Yang, et al., Chem. Commun. 56 (2020) 1597–1600.

doi: 10.1039/C9CC09387G

L. Pang, X. Li, S.C. Ren, et al., Nano Res. 15 (2022) 7091–7098.

doi: 10.1007/s12274-022-4395-2

A. Bavykina, N. Kolobov, I.S. Khan, et al., Chem. Rev. 120 (2020) 8468–8535.

doi: 10.1021/acs.chemrev.9b00685

T. Xia, Y. Lin, W. Li, M. Ju, Chin. Chem. Lett. 32 (2021) 2975–2984.

doi: 10.1016/j.cclet.2021.02.058

C.A. Trickett, A. Helal, B.A. Al-Maythalony, et al., Nat. Rev. Mater. 2 (2017) 17045.

doi: 10.1038/natrevmats.2017.45

Q. Shen, X. Li, R. Li, Y. Wu, ACS Sustain. Chem. Eng. 8 (2020) 17608–17621.

doi: 10.1021/acssuschemeng.0c06849

A. Dhakshinamoorthy, A.M. Asiri, H. Garcia, Chem. Eur. J. 22 (2016) 8012–8024.

doi: 10.1002/chem.201505141

L. Cao, Z. Lin, F. Peng, et al., Angew. Chem. Int. Ed. 55 (2016) 4962–4966.

doi: 10.1002/anie.201512054

T. Sawano, Z. Lin, D. Boures, et al., J. Am. Chem. Soc. 138 (2016) 9783–9786.

doi: 10.1021/jacs.6b06239

Z. Zhang, L. Bai, X. Hu, Chem. Sci. 10 (2019) 3791–3795.

doi: 10.1039/C9SC00126C

Z. Yu, Z. Song, C. Lu, et al., Appl. Organomet. Chem. 36 (2022) e6648.

doi: 10.1002/aoc.6648

G. Pan, C. Hu, S. Hong, et al., Nat. Commun. 12 (2021) 64.

doi: 10.1038/s41467-020-20233-w

B. Marciniec, Hydrosilylation: A Comprehensive Review on Recent Advances, Springer Science, 2009.

E. Rémond, C. Martin, J. Martinez, F. Cavelier, Chem. Rev. 116 (2016) 11654–11684.

doi: 10.1021/acs.chemrev.6b00122

R. Ramesh, D.S. Reddy, J. Med. Chem. 61 (2018) 3779–3798.

doi: 10.1021/acs.jmedchem.7b00718

L. Li, Y.L. Wei, L.W. Xu, Synlett 31 (2020) 21–34.

doi: 10.1055/s-0039-1691496

F. Ye, Z. Xu, L.W. Xu, Acc. Chem. Res. 54 (2021) 452–470.

doi: 10.1021/acs.accounts.0c00740

F. Ye, L.W. Xu, Synlett 32 (2021) 1281–1288.

doi: 10.1055/a-1408-6795

L.X.W. Huang, Chin. J. Org. Chem. 41 (2021) 4515–4516.

doi: 10.6023/cjoc202100080

H. Wang, X. Zhang, Y. Li, L.W. Xu, Angew. Chem. Int. Ed. 61 (2022) e202210851.

doi: 10.1002/anie.202210851

X. Zhang, J. Fang, C. Cai, G. Lu, Chin. Chem. Lett. 32 (2021) 1280–1292.

doi: 10.1016/j.cclet.2020.09.058

L.H. Sommer, E.W. Pietrusza, F.C. Whitmore, J. Am. Chem. Soc. 69 (1947) 188-188.

J.L. Speier, J.A. Webster, G.H. Barnes, J. Am. Chem. Soc. 79 (1957) 974–979.

doi: 10.1021/ja01561a054

B. Karstedt, Patent: US3775452A, 1973.

L.D. de Almeida, H. Wang, K. Junge, X. Cui, M. Beller, Angew. Chem. Int. Ed. 60 (2021) 550–565.

doi: 10.1002/anie.202008729

P.F. Fu, L. Brard, Y. Li, T.J. Marks, J. Am. Chem. Soc. 117 (1995) 7157–7168.

doi: 10.1021/ja00132a015

K. Takaki, K. Sonoda, T. Kousaka, et al., Tetrahedron Lett. 42 (2001) 9211–9214.

doi: 10.1016/S0040-4039(01)02027-5

J. Li, C. Zhao, J. Liu, et al., Inorg. Chem. 55 (2016) 9105–9111.

doi: 10.1021/acs.inorgchem.6b01670

D.S. Levine, T.D. Tilley, R.A. Andersen, Chem. Commun. 53 (2017) 11881–11884.

doi: 10.1039/C7CC06417A

J. Liu, W. Chen, J. Li, C. Cui, ACS Catal. 8 (2018) 2230–2235.

doi: 10.1021/acscatal.8b00010

X. Liu, Q. Wen, L. Xiang, X. Leng, Y. Chen, Chem. Eur. J. 26 (2020) 5494–5499.

doi: 10.1002/chem.202000342

W. Chen, H. Song, J. Li, C. Cui, Angew. Chem. Int. Ed. 59 (2020) 2365–2369.

doi: 10.1002/anie.201913773

W. Chen, C. Jiang, J. Zhang, et al., J. Am. Chem. Soc. 143 (2021) 12913–12918.

doi: 10.1021/jacs.1c04689

S. Zhu, W. Xu, D. Hong, et al., Inorg. Chem. 62 (2023) 381–391.

doi: 10.1021/acs.inorgchem.2c03488

Q.J. Miao, Z.P. Fang, G.P. Cai, Catal. Commun. 4 (2003) 637–639.

doi: 10.1016/j.catcom.2003.10.006

B. Marciniec, K. Szubert, M.J. Potrzebowski, I. Kownacki, K. Łȩszczak, Angew. Chem. Int. Ed. 47 (2008) 541–544.

doi: 10.1002/anie.200704362

B. Marciniec, K. Szubert, R. Fiedorow, et al., J. Mol. Catal. A: Chem. 310 (2009) 9–16.

doi: 10.1016/j.molcata.2009.05.013

B. Marciniec, K. Szubert, M.J. Potrzebowski, I. Kownacki, H. Maciejewski, ChemCatChem 1 (2009) 304–310.

doi: 10.1002/cctc.200900111

K. Motokura, K. Maeda, W.J. Chun, ACS Catal. 7 (2017) 4637–4641.

doi: 10.1021/acscatal.7b01523

K. Maeda, Y. Uemura, M. Kim, et al., J. Phy. Chem. C 123 (2019) 14556–14563.

doi: 10.1021/acs.jpcc.9b03280

K. Usui, K. Miyashita, K. Maeda, et al., Org. Lett. 21 (2019) 9372–9376.

doi: 10.1021/acs.orglett.9b03602

K. Usui, Y. Manaka, W.J. Chun, K. Motokura, Chem. Eur. J. 28 (2022) e202104001.

doi: 10.1002/chem.202104001

J. Li, C. Yang, L. Zhang, T. Ma, J. Organomet. Chem. 696 (2011) 1845–1849.

doi: 10.1016/j.jorganchem.2011.02.021

F. Li, Y. Li, J. Mol. Catal. A: Chem. 420 (2016) 254–263.

doi: 10.1016/j.molcata.2016.04.019

D. Shao, Y. Li, RSC Adv. 8 (2018) 20379–20393.

doi: 10.1039/C8RA01828F

A.J. Chalk, J.F. Harrod, J. Am. Chem. Soc. 87 (1965) 16–21.

doi: 10.1021/ja01079a004

R. Ciriminna, V. Pandarus, G. Gingras, F. Béland, M. Pagliaro, ACS Sustain. Chem. Eng. 1 (2013) 249–253.

doi: 10.1021/sc3001096

V. Pandarus, R. Ciriminna, G. Gingras, et al., Green Chem. 21 (2019) 129–140.

doi: 10.1039/C8GC02569J

J.W. Zhang, G.P. Lu, C. Cai, Green Chem. 19 (2017) 2535–2540.

doi: 10.1039/C7GC00818J

R. Hu, L. Zha, M. Cai, Catal. Commun. 11 (2010) 563–566.

doi: 10.1016/j.catcom.2009.12.020

R. Hu, W. Hao, M. Cai, Chin. J. Chem. 29 (2011) 1629–1634.

doi: 10.1002/cjoc.201180292

D. Do Van, T. Hosokawa, M. Saito, Y. Horiuchi, M. Matsuoka, Appl. Catal. A: Gen. 503 (2015) 203–208.

doi: 10.1016/j.apcata.2015.05.039

D. Van Do, T. Hosokawa, Y. Horiuchi, M. Matsuoka, Res. Chem. Interm. 46 (2020) 5297–5306.

doi: 10.1007/s11164-020-04263-z

Y. Huo, J. Hu, S. Lin, et al., Appl. Organomet. Chem. 33 (2019) e4874.

doi: 10.1002/aoc.4874

T. Galeandro-Diamant, R. Sayah, M.L. Zanota, et al., Chem. Commun. 53 (2017) 2962–2965.

doi: 10.1039/C6CC10154B

D.G. Dobó, D. Sipos, A. Sápi, et al., Catalysts 8 (2018) 22.

doi: 10.3390/catal8010022

W. Chen, Z. Xie, H. Liang, et al., RSC Adv. 10 (2020) 3175–3183.

doi: 10.1039/C9RA09082G

H. Zai, Y. Zhao, S. Chen, et al., RSC Adv. 6 (2016) 98520–98527.

doi: 10.1039/C6RA16944A

J. Zhao, Y. Gui, Y. Liu, et al., Catal. Lett. 147 (2017) 1127–1132.

doi: 10.1007/s10562-017-1984-x

H. Zai, Y. Zhao, S. Chen, et al., Nano Res. 11 (2018) 2544–2552.

doi: 10.1007/s12274-017-1879-6

L. Li, Y. Li, A. Assefa, J.J. Bao, Transit. Metal Chem. 44 (2019) 779–787.

doi: 10.1007/s11243-019-00348-w

L. Li, Y. Li, J. Yan, et al., RSC Adv. 9 (2019) 12696–12709.

doi: 10.1039/C9RA00375D

Y. Huo, J. Hu, Y. Tu, et al., J. Organomet. Chem. 936 (2021) 121714.

doi: 10.1016/j.jorganchem.2021.121714

O. Bartlewicz, M. Zieliński, M. Kaczmarek, H. Maciejewski, Mol. Catal. 509 (2021) 111615.

doi: 10.1016/j.mcat.2021.111615

Y. Naganawa, Y. Maegawa, H. Guo, et al., Dalton Trans. 48 (2019) 5534–5540.

doi: 10.1039/C9DT00078J

Y. Zhu, S. Murali, W. Cai, et al., Adv. Mater. 22 (2010) 3906–3924.

doi: 10.1002/adma.201001068

F. Rao, S. Deng, C. Chen, N. Zhang, Catal. Commun. 46 (2014) 1–5.

doi: 10.1016/j.catcom.2013.10.043

C.J. Kong, S.E. Gilliland, B.R. Clark, B.F. Gupton, Chem. Commun. 54 (2018) 13343–13346.

doi: 10.1039/C8CC07641C

Y. Zhu, T. Cao, C. Cao, et al., ACS Catal. 8 (2018) 10004–10011.

doi: 10.1021/acscatal.8b02624

J. Wen, Y. Chen, S. Ji, et al., Nano Res. 12 (2019) 2584–2588.

doi: 10.1007/s12274-019-2490-9

A. Mollar-Cuni, P. Borja, S. Martin, G. Guisado-Barrios, J.A. Mata, Eur. J. Inorg. Chem. 2020 (2020) 4254–4262.

doi: 10.1002/ejic.202000356

Y. Han, Y. Xiong, C. Liu, et al., J. Catal. 396 (2021) 351–359.

doi: 10.1016/j.jcat.2021.03.004

B. Sánchez-Page, M.V. Jiménez, J.J. Pérez-Torrente, et al., ACS Appl. Nano Mater. 3 (2020) 1640–1655.

doi: 10.1021/acsanm.9b02398

D.V. Jawale, V. Geertsen, F. Miserque, et al., Green Chem. 23 (2021) 815–820.

doi: 10.1039/D0GC03943H

X. Feng, J. Guo, S. Wang, Q. Wu, Z. Chen, J. Mater. Chem. A 9 (2021) 17885–17892.

doi: 10.1039/D1TA05528C

R. Jiménez, J.M. López, J. Cervantes, Can. J. Chem. 78 (2000) 1491–1495.

doi: 10.1139/v00-086

A.M. Caporusso, L.A. Aronica, E. Schiavi, et al., J. Organomet. Chem. 690 (2005) 1063–1066.

doi: 10.1016/j.jorganchem.2004.10.051

S. Carrettin, P. Concepción, A. Corma, J.M. López Nieto, V.F. Puntes, Angew. Chem. Int. Ed. 43 (2004) 2538–2540.

doi: 10.1002/anie.200353570

A. Corma, C. Gonzalez-Arellano, M. Iglesias, F. Sanchez, Angew. Chem. Int. Ed. 46 (2007) 7820–7822.

doi: 10.1002/anie.200702032

A. Psyllaki, I.N. Lykakis, M. Stratakis, Tetrahedron 68 (2012) 8724–8731.

doi: 10.1016/j.tet.2012.08.021

N. Sabourault, G. Mignani, A. Wagner, C. Mioskowski, Org. Lett. 4 (2002) 2117–2119.

doi: 10.1021/ol025658r

S. Putzien, E. Louis, O. Nuyken, F.E. Kühn, Catal. Sci. Technol. 2 (2012) 725–729.

doi: 10.1039/C2CY00367H

F. Alonso, R. Buitrago, Y. Moglie, et al., J. Organomet. Chem. 696 (2011) 368–372.

doi: 10.1016/j.jorganchem.2010.09.068

X. Cui, K. Junge, X. Dai, et al., ACS Cent. Sci. 3 (2017) 580–585.

doi: 10.1021/acscentsci.7b00105

H. Miura, S. Sasaki, R. Ogawa, T. Shishido, Eur. J. Org. Chem. 2018 (2018) 1858–1862.

doi: 10.1002/ejoc.201800224

Y. Chen, S. Ji, W. Sun, et al., J. Am. Chem. Soc. 140 (2018) 7407–7410.

doi: 10.1021/jacs.8b03121

L. Chen, G.E. Sterbinsky, S.L. Tait, J. Catal. 365 (2018) 303–312.

doi: 10.1016/j.jcat.2018.07.004

L. Chen, I.S. Ali, S.L. Tait, ChemCatChem 12 (2020) 3576–3584.

doi: 10.1002/cctc.202000085

X. Zhou, L. Chen, G.E. Sterbinsky, et al., Catal. Sci. Technol. 10 (2020) 3353–3365.

doi: 10.1039/C9CY02594D

B.B. Sarma, J. Kim, J. Amsler, et al., Angew. Chem. Int. Ed. 59 (2020) 5806–5815.

doi: 10.1002/anie.201915255

M. Li, S. Zhao, J. Li, et al., Nano Res. 15 (2022) 5857–5864.

doi: 10.1007/s12274-022-4227-4

T. Mitsudome, S. Fujita, M. Sheng, et al., Green Chem. 21 (2019) 4566–4570.

doi: 10.1039/C9GC01981B

R. Azuma, S. Nakamichi, J. Kimura, et al., ChemCatChem 10 (2018) 2378–2382.

doi: 10.1002/cctc.201800161

C. Kan, X. Kong, C. Du, D. Liu, Polym. J. 34 (2002) 97–102.

doi: 10.1295/polymj.34.97

A. Kowalewska, J. Organomet. Chem. 693 (2008) 2193–2199.

doi: 10.1016/j.jorganchem.2008.03.021

Y. Bai, J. Peng, Y. Hu, J. Li, G. Lai, J. Fluorine Chem. 132 (2011) 123–127.

doi: 10.1016/j.jfluchem.2010.12.007

Y. Bai, S. Zhang, Y. Deng, et al., J. Colloid Interface Sci. 394 (2013) 428–433.

doi: 10.1016/j.jcis.2012.11.048

M. Planellas, W. Guo, F. Alonso, et al., Adv. Syn. Catal. 356 (2014) 179–188.

doi: 10.1002/adsc.201300641

W. Guo, R. Pleixats, A. Shafir, T. Parella, Adv. Syn. Catal. 357 (2015) 89–99.

doi: 10.1002/adsc.201400740

R.H. Li, X.M. An, Y. Yang, et al., Org. Lett. 20 (2018) 5023–5026.

doi: 10.1021/acs.orglett.8b02176

Y.N. Jiang, J.H. Zeng, Y. Yang, et al., Chem. Commun. 56 (2020) 1597–1600.

doi: 10.1039/C9CC09387G

L. Pang, X. Li, S.C. Ren, et al., Nano Res. 15 (2022) 7091–7098.

doi: 10.1007/s12274-022-4395-2

A. Bavykina, N. Kolobov, I.S. Khan, et al., Chem. Rev. 120 (2020) 8468–8535.

doi: 10.1021/acs.chemrev.9b00685

T. Xia, Y. Lin, W. Li, M. Ju, Chin. Chem. Lett. 32 (2021) 2975–2984.

doi: 10.1016/j.cclet.2021.02.058

C.A. Trickett, A. Helal, B.A. Al-Maythalony, et al., Nat. Rev. Mater. 2 (2017) 17045.

doi: 10.1038/natrevmats.2017.45

Q. Shen, X. Li, R. Li, Y. Wu, ACS Sustain. Chem. Eng. 8 (2020) 17608–17621.

doi: 10.1021/acssuschemeng.0c06849

A. Dhakshinamoorthy, A.M. Asiri, H. Garcia, Chem. Eur. J. 22 (2016) 8012–8024.

doi: 10.1002/chem.201505141

L. Cao, Z. Lin, F. Peng, et al., Angew. Chem. Int. Ed. 55 (2016) 4962–4966.

doi: 10.1002/anie.201512054

T. Sawano, Z. Lin, D. Boures, et al., J. Am. Chem. Soc. 138 (2016) 9783–9786.

doi: 10.1021/jacs.6b06239

Z. Zhang, L. Bai, X. Hu, Chem. Sci. 10 (2019) 3791–3795.

doi: 10.1039/C9SC00126C

Z. Yu, Z. Song, C. Lu, et al., Appl. Organomet. Chem. 36 (2022) e6648.

doi: 10.1002/aoc.6648

G. Pan, C. Hu, S. Hong, et al., Nat. Commun. 12 (2021) 64.

doi: 10.1038/s41467-020-20233-w

Ruiying Liu , Li Zhao , Baishan Liu , Jiayuan Yu , Yujie Wang , Wanqiang Yu , Di Xin , Chaoqiong Fang , Xuchuan Jiang , Riming Hu , Hong Liu , Weijia Zhou . Modulating pollutant adsorption and peroxymonosulfate activation sites on Co3O4@N,O doped-carbon shell for boosting catalytic degradation activity. Chinese Journal of Structural Chemistry, 2024, 43(8): 100332-100332. doi: 10.1016/j.cjsc.2024.100332

Haoran Shi , Jiaxin Wang , Yuqin Zhu , Hongyang Li , Guodong Ju , Lanlan Zhang , Chao Wang . Highly selective α-C(sp3)-H arylation of alkenyl amides via nickel chain-walking catalysis. Chinese Chemical Letters, 2024, 35(7): 109333-. doi: 10.1016/j.cclet.2023.109333

Zhenkang Ai , Hui Chen , Xuebin Liao . Nickel-catalyzed decarboxylative difluoromethylation and alkylation of alkenes. Chinese Chemical Letters, 2025, 36(3): 109954-. doi: 10.1016/j.cclet.2024.109954

Er-Meng Wang , Ziyi Wang , Xu Ban , Xiaowei Zhao , Yanli Yin , Zhiyong Jiang . Chemoselective photocatalytic sulfenylamination of alkenes with sulfenamides via energy transfer. Chinese Chemical Letters, 2024, 35(12): 109843-. doi: 10.1016/j.cclet.2024.109843

Fan Chen , Xiaoyu Zhao , Weihang Miao , Yingying Li , Ye Yuan , Lingling Chu . Regio- and enantioselective hydrofluorination of internal alkenes via nickel-catalyzed hydrogen atom transfer. Chinese Chemical Letters, 2025, 36(5): 110239-. doi: 10.1016/j.cclet.2024.110239

Shuai Tang , Zian Wang , Mengyi Zhu , Xinyun Zhao , Xiaoyun Hu , Hua Zhang . Synthesis of organoboron compounds via heterogeneous C–H and C–X borylation. Chinese Chemical Letters, 2025, 36(5): 110503-. doi: 10.1016/j.cclet.2024.110503

Wen-Jing Li , Jun-Bo Wang , Yu-Heng Liu , Mo Zhang , Zhan-Hui Zhang . Molybdenum-doped carbon nitride as an efficient heterogeneous catalyst for direct amination of nitroarenes with arylboronic acids. Chinese Chemical Letters, 2025, 36(3): 110001-. doi: 10.1016/j.cclet.2024.110001

Chong-Yang Shi , Jian-Xing Gong , Zhen Li , Chao Shu , Long-Wu Ye , Qing Sun , Bo Zhou , Xin-Qi Zhu . Gold-catalyzed intermolecular amination of allyl azides with ynamides: Efficient construction of 3-azabicyclo[3.1.0] scaffold. Chinese Chemical Letters, 2025, 36(2): 109895-. doi: 10.1016/j.cclet.2024.109895

Baokang Geng , Xiang Chu , Li Liu , Lingling Zhang , Shuaishuai Zhang , Xiao Wang , Shuyan Song , Hongjie Zhang . High-efficiency PdNi single-atom alloy catalyst toward cross-coupling reaction. Chinese Chemical Letters, 2024, 35(7): 108924-. doi: 10.1016/j.cclet.2023.108924

Hua Liu , Jian Zhao , Qi Li , Xiang-Yu Zhang , Zhi-Wei Zheng , Kun Huang , Da-Bin Qin , Bin Zhao . Indium-captured zirconium-porphyrin frameworks displaying rare multi-selectivity for catalytic transfer hydrogenation of aldehydes and ketones. Chinese Chemical Letters, 2025, 36(6): 110593-. doi: 10.1016/j.cclet.2024.110593

Chengyao Zhao , Jingyuan Liao , Yuxiang Zhu , Yiying Zhang , Lianjie Zhai , Junrong Huang , Hengzhi You . Polystyrene-supported phosphoric-acid catalyzed atroposelective construction of axially chiral N-aryl benzimidazoles. Chinese Chemical Letters, 2025, 36(6): 110337-. doi: 10.1016/j.cclet.2024.110337

Danqing Wu , Jiajun Liu , Tianyu Li , Dazhen Xu , Zhiwei Miao . Research Progress on the Simultaneous Construction of C—O and C—X Bonds via 1,2-Difunctionalization of Olefins through Radical Pathways. University Chemistry, 2024, 39(11): 146-157. doi: 10.12461/PKU.DXHX202403087

Hao-Cong Li , Ming Zhang , Qiyan Lv , Kai Sun , Xiao-Lan Chen , Lingbo Qu , Bing Yu . Homogeneous catalysis and heterogeneous separation: Ionic liquids as recyclable photocatalysts for hydroacylation of olefins. Chinese Chemical Letters, 2025, 36(2): 110579-. doi: 10.1016/j.cclet.2024.110579

Honghong Zhang , Zhen Wei , Derek Hao , Lin Jing , Yuxi Liu , Hongxing Dai , Weiqin Wei , Jiguang Deng . Recent advances in synergistic catalytic valorization of CO2 and hydrocarbons by heterogeneous catalysis. Acta Physico-Chimica Sinica, 2025, 41(7): 100073-0. doi: 10.1016/j.actphy.2025.100073

Yi-Fan Wang , Hao-Yun Yu , Hao Xu , Ya-Jie Wang , Xiaodi Yang , Yu-Hui Wang , Ping Tian , Guo-Qiang Lin . Rhodium(Ⅲ)-catalyzed diastereo- and enantioselective hydrosilylation/cyclization reaction of cyclohexadienone-tethered α, β-unsaturated aldehydes. Chinese Chemical Letters, 2024, 35(9): 109520-. doi: 10.1016/j.cclet.2024.109520

Kun Tang , Fen Su , Shijie Pan , Fengfei Lu , Zhongfu Luo , Fengrui Che , Xingxing Wu , Yonggui Robin Chi . Enones from aldehydes and alkenes by carbene-catalyzed dehydrogenative couplings. Chinese Chemical Letters, 2024, 35(9): 109495-. doi: 10.1016/j.cclet.2024.109495

Boqiang Wang , Yongzhuo Xu , Jiajia Wang , Muyang Yang , Guo-Jun Deng , Wen Shao . Transition-metal free trifluoromethylimination of alkenes enabled by direct activation of N-unprotected ketimines. Chinese Chemical Letters, 2024, 35(9): 109502-. doi: 10.1016/j.cclet.2024.109502

Yunqiang Li , Yongxian Huang , Sinuo Li , He Huang , Zhiwei Jiao . Elaborating azaaryl alkanes enabled by photoredox/palladium dual catalyzed dialkylation of azaaryl alkenes. Chinese Chemical Letters, 2025, 36(4): 110051-. doi: 10.1016/j.cclet.2024.110051

Chonglong He , Yulong Wang , Quan-Xin Li , Zichen Yan , Keyuan Zhang , Shao-Fei Ni , Xin-Hua Duan , Le Liu . Alkylarylation of alkenes with arylsulfonylacetate as bifunctional reagent via photoredox radical addition/Smiles rearrangement cascade. Chinese Chemical Letters, 2025, 36(5): 110253-. doi: 10.1016/j.cclet.2024.110253

Xiao-Ming Chen , Lianhui Song , Jun Pan , Fei Zeng , Yi Xie , Wei Wei , Dong Yi . Visible-light-induced four-component difunctionalization of alkenes to construct phosphorodithioate-containing quinoxalin-2(1H)-ones. Chinese Chemical Letters, 2024, 35(11): 110112-. doi: 10.1016/j.cclet.2024.110112