Recent advances in functional utilisation of environmentally friendly and recyclable high-performance green biocomposites: A review

-

* Corresponding author.

E-mail address: geshengbo@njfu.edu.cn (S. Ge)

Citation:

Guiyang Zheng, Xuelian Kang, Haoran Ye, Wei Fan, Christian Sonne, Su Shiung Lam, Rock Keey Liew, Changlei Xia, Yang Shi, Shengbo Ge. Recent advances in functional utilisation of environmentally friendly and recyclable high-performance green biocomposites: A review[J]. Chinese Chemical Letters,

;2024, 35(4): 108817.

doi:

10.1016/j.cclet.2023.108817

Petroleum-based polymers and metal materials with high strength and flexibility have become the basic requirements of modern materials [1-3]. However, the production of metal materials and petroleum-based polymers is associated with the emission of solid atmospheric particles, dust pollution and global warming [4,5]. Consequently, there is a need for alternative environmentally friendly and sustainable materials to mitigate these environmental issues [6]. There are various alternatives, including the substitution of synthetic polymers with biomass materials, which has been the current research focus [7].

Efforts have been made to develop biomaterials that are completely biodegradable and environmentally friendly [8]. Biocomposites with ideal properties conforming to the definition of “green” are created using natural fibres as the basis material [9]. Considering the limited size of natural fibres, it is necessary to cross-link and bond the fibres artificially to prepare various biocomposites [10]. For this reason, filler polymers are needed between the fibres as an intermediate product that connects them and imparts bond strength in the material [11,12]. At present, petroleum-based resin adhesives are primarily used as filler polymers in biocomposites because they possess high bonding strengths and good water resistance [13]. Since the original intention was to develop green composite materials, the consumption of petroleum resources and the release of formaldehyde have undermined that goal [14]. Therefore, the ability of green biocomposites to completely degrade into the water and carbon dioxide in nature determines whether the material is “environmentally friendly” and “recyclable”. Then, optimal results could be achieved by selecting appropriate substrates and reinforcement materials [15,16].

The study of high-performance and functional biocomposite has always been the focus of material scholars [17,18]. Despite being a great alternative to high-pollution materials, green biocomposite materials still have to meet social demand. Plant biomass is readily available, less expensive, and more suitable as a composite material reinforcement than animal and bacterial biomass [19]. Plant species contain various materials that provide mechanical strength to their stems [20]. In addition to being lightweight and high-strength, plant fibres are also useful reinforcement materials for consideration [21]. However, plant biomass cannot be used on large scales due to its poor durability and mechanical properties [22,23]. The current simple and direct application cannot effectively exploit the advantages of plant biomass, hence these resources are usually modified to cater to modern materials requirements [24,25]. Biomass engineering materials have been demonstrated to solve the problems related to fibre water resistance and compatibility. For instance, water/aerogels generally use cellulose skeletons to add and modify functional groups on the skeletons, which enhances the adsorption capacity and water retention properties of biomass gels [26,27].

Currently, there are two types of methods for preparing biocomposites based on their structural characteristics. “Top-down” biocomposite preparation uses the structure and properties of biomass to synthesise composite materials adopting lightweight directional plant fibre as an excellent skeleton [28,29]. From a macro perspective, this production method is simple, effective, and cheaper, which allows for massive supply. As oppose to that, the “bottom-up” method has gradually gained acceptance as increasing awareness of biomass structures and the maturity of micro/nano structures. Biocomposites can be constructed layer-by-layer using natural fibres as scaffolds and templates. In addition, the large interfacial area and tunable properties of micro-nano interfaces make them ideal for potential functional applications as well as the replacement of traditional materials for the inlay of subsequent scaffolds [30]. In the preparation of biocomposites, the “bottom-up” preparation method can effectively control the inherent structural defects of natural biomass itself, thus obtaining better performance. In addition, it has more functional possibilities due to the structure being built from the ground up [31,32].

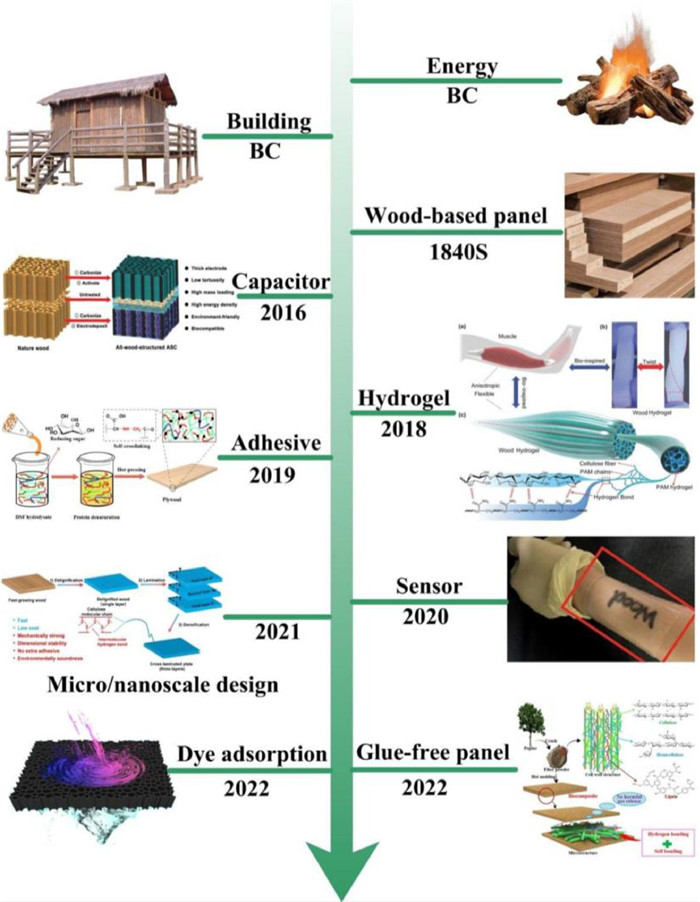

With the above two methods, many reports have been published on the preparation of new engineering, adsorption, and conductive materials from biomass, suggesting the broad application prospects of biocomposite materials. However, the biocomposites reviewed in the existing reviews usually focus on obtaining better performance, while ignoring the advantages of biomass recycling. There have been recent reports on high-performance multifunctional green biomass composites that are fully recyclable and pollution-free [33,34]. Hence, this article reviews the aspects of recyclable high-performance functional composite materials prepared from biomass and the existing green biocomposites, discusses the potential future of green biocomposites, retrieves the recent development overview of green biocomposites from the aspects of preparation technology and applications, expounds the requirements and development trends of green biocomposites, and provides development prospects for green biocomposites (Fig. 1) [35-41].

"Green biocomposites" refers to composite materials that are environmentally friendly, biodegradable and derived from renewable resources [42,43]. Currently, biomass is primarily employed as a reinforcement material, and its high specific strength and ordered three-dimensional structure make it effective as the raw materials for composites [44,45]. However, most composite materials are from non-renewable petroleum-based polymers or problematic inorganic substances [46]. Accordingly, green biocomposites can be prepared using degradable biomass or natural polymers extracted as a matrix with natural fibre as reinforcement [47,48]. Nevertheless, it should be noted that biomass has structural defects and a low industrial scale, resulting in inferior performance and preparation costs compared to highly polluting materials, such as metals and petroleum-based materials [49,50]. In view of this, the modification of mechanical strength and optimisation of the preparation process to adapt to large-scale production represents the exciting research focus in biocomposites [51,52].

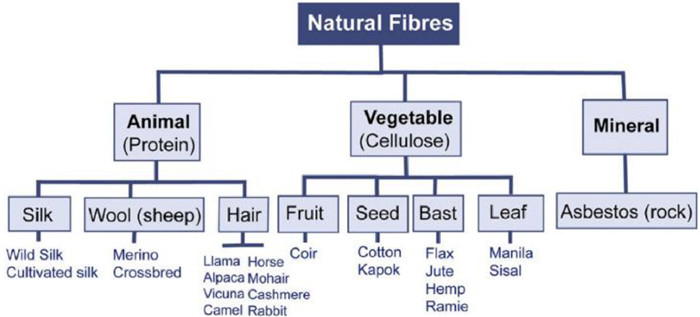

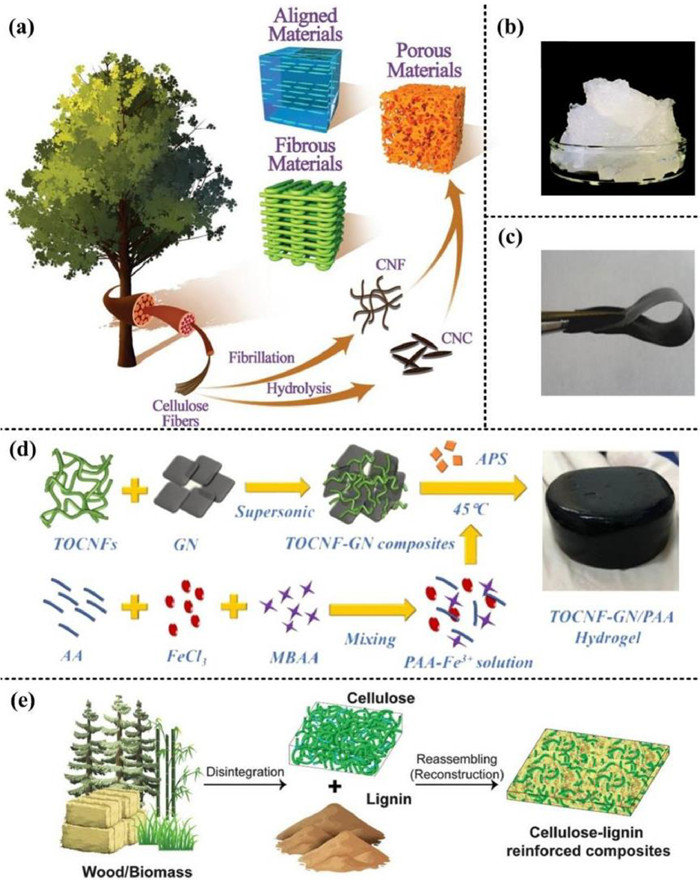

The majority of biocomposites are made by extracting natural fibres from plant biomass or directly using the fibre framework found within the biomass itself (Fig. 2 and Table 1) [53-56]. Lignocellulosic components could be a suitable substrate for reinforcing green biocomposites [57]. Additionally, fibres from mammals and insects including silk, possess relevant chemical components to fabricate green biocomposite materials. Unfortunately, its usage is restricted due to its expensive price, limited availability, and limited sources, mass production encountered difficulties [58-60].

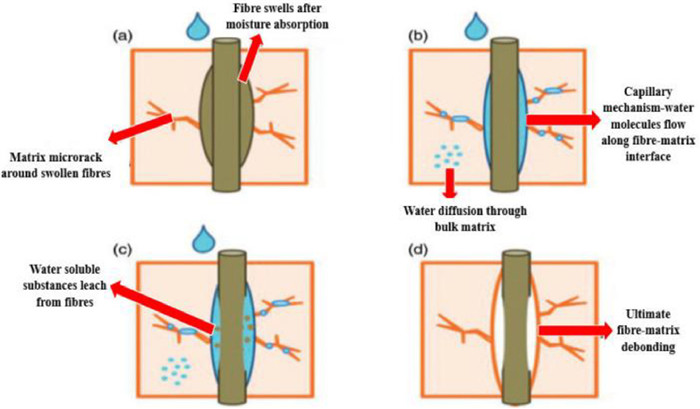

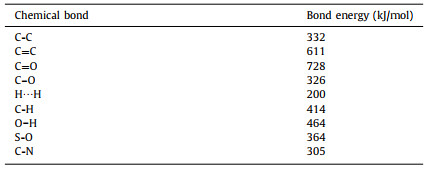

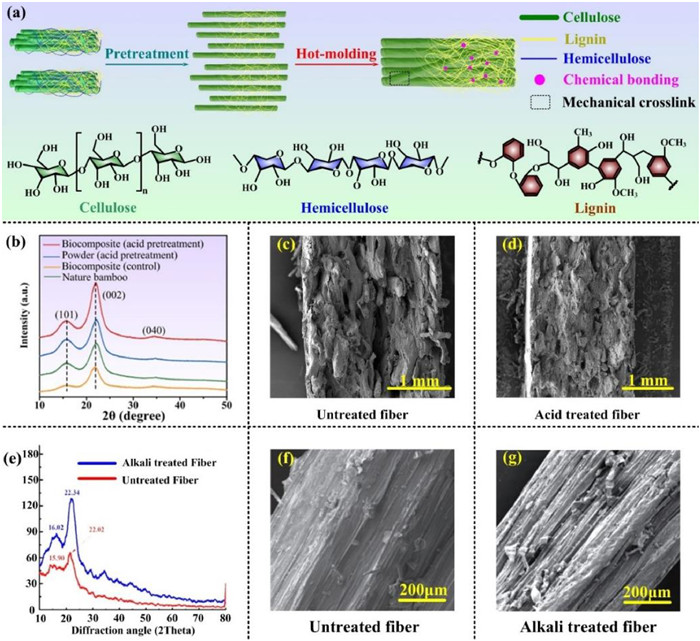

In light of their straight structure and rich functional groups, plant fibres are ideal for targeted modification [61]. Despite this, the substantial amounts of hydroxyl groups found in natural fibres is caused by hemicellulose and amorphous cellulose; this makes the fibre structure easy to degrade (Figs. 3a-d) [62,63]. Since the matrix and fibre are usually combined through hydrogen bonds that possess low bond energy (Table 2) [64], hydrogen bonds can be easily broken under various conditions [65]. Thus, the combination of fibres and matrix becomes loose and subsequently resulting in poor mechanical properties. As such, adequate modifications should be performed to enhance the bonding strength and mechanical characteristics. amongst the commonly used modification methods such as treatment of silane, acetylation, toluoylation and permanganate, acid/alkali treatment represent the greener and simpler method to pretreat the product [66]. It was found that when the appropriate temperature and acid/alkali concentrations were applied, the main contributor to hydroxyl groups (i.e., hemicellulose and Amorphous region of cellulose) in plant fibres was removed, which improved the water resistance of the fibres. Upon acid/alkali treatment, the surface becomes rougher and the increased surface area provides an avenue for subsequent functionalisation [67,68].

|

According to Zheng et al. [69], bamboo fibres can be successfully treated by a simple acid treatment followed by mechanical ball milling. The combined action of the ball mill and acidic conditions resulted in decreased hemicellulose content in the fibres and increased relative cellulose content (Fig. 4a). As can be seen from the SEM picture and XRD pattern, bamboo fibres are more compatible with composite materials prepared after acid treatment (Figs. 4b-d). Thus, the increase in the proportion of fibre crystallisation area greatly enhances the water-resistance of the fibre. In a study by Vijay et al. [70], the alkali treatment of natural fibres obtained from three-edged moss resulted in smaller diameters as well as a rougher surface. The results indicate that the alkali treatment removes the amorphous region and hemicellulose of the fibre. The XRD peaks showed that the damage is concentrated in the amorphous regions of cellulose, hemicellulose, and lignin, which is evident from the increased intensity of peaks after alkali treatment (Fig. 4e). Through the destruction of amorphous cellulose and hemicellulose, free hydroxyl groups are reduced and fibre compatibility is increased (Figs. 4f and g). Table 3 [71-79] shows the treatment processes.

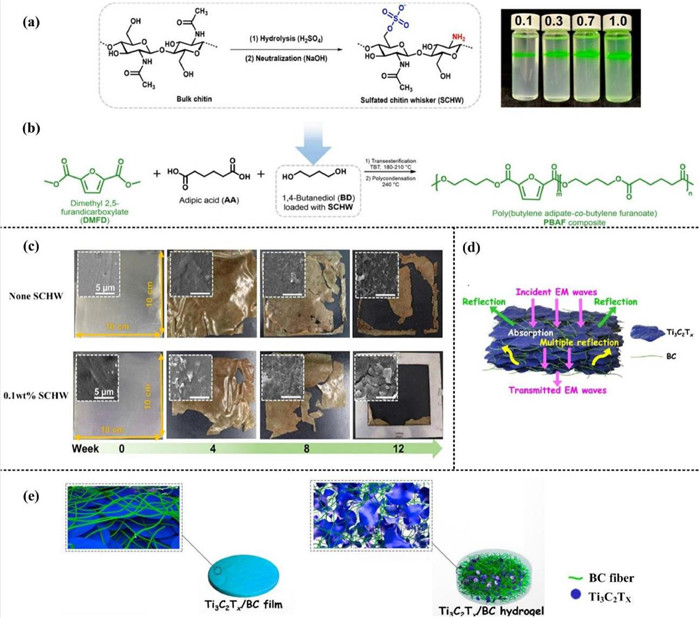

The study of biomass is not limited to plant fibres, but also includes studies on animals and bacteria [80,81]. A degradable biomass-derived poly(polybutadiene adipate-co-furanoate) (PBAF) has been developed from sulfated chitin nanowhiskers (SCHWs) under alkaline conditions (Fig. 5a) [82]. The polymerised film produced by SCHW is easier to degrade (Figs. 5b and c), and the degradation products produced are harmless, which highlights its great potential beyond the laboratory. Recent research also focuses on existing bacterial cellulose preparation technologies [83]. A functionalised bacterial cellulose solution was proposed by Gilbert et al. [84] to maximise the use of bacterial cellulose with high fineness and crystallinity as biomass. Through an in situ synthesis technique, Wan et al. [85] developed a composite film of Ti3C2Tx MXene and bacterial cellular (BC) that is ultrathin, strong, and highly flexible. This ultrathin film has both electrical conductivity and mechanical strength suitable for electromagnetic interference (EMI) shielding applications (Fig. 5d). As a result of this approach, Ti3C2Tx MXene nanosheets are uniformly dispersed through the 3D BC network to provide the film with excellent mechanical strength and flexibility (Fig. 5e).

Biocomposite materials require a matrix that integrates reinforcement efficiently to maximise material performance through internal interactions. The matrix serves the purposes of bonding, balancing and dispersing loads as well as protecting the fibres. In this regard, the choice of matrix and reinforcement for green biomass composite materials is different. The natural adhesive properties of lignin, chitin, and proteins make them suitable for use as biomass substrates.

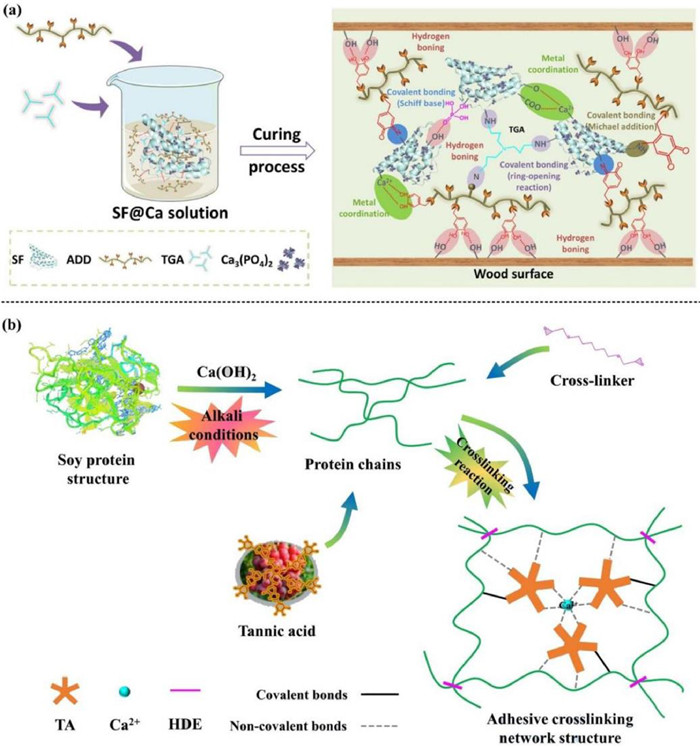

There are several types of proteins with wide sources plus easy modification options. Proteins are usually incorporated into adhesive substrates as substrates. However, proteins have hydrophilic groups on their surfaces, and green biocomposites prepared with protein-based adhesives would have poor water resistance. Hence, modifications are necessary to the protein matrix to improve water resistance and binding strength for green biocomposites [86]. Zhang et al. prepared a strong viscous actuation by gecko toe brush-like structure through bionic gecko toe and oyster bio-mineralised structure. A bio-mineralised structure is formed when Ca3(PO4)2 binds to soybean protein (SP) through this polymer (Fig. 6a) [87]. Mildew resistance and flame-retardant properties are improved as a result of this inorganic-organic composite structure. In addition, Bai et al. forms a stable and tough cross-linked network inside the protein through strong metal coordination and increased covalent bonds, endowing the adhesive with better performance (Fig. 6b) [88]. Notably, these biomass adhesives serve as a good matrix and are considerably greener than resin or petroleum macromolecular polymers.

It is still premature to consider protein adhesives to be the preferred alternative to petroleum-based materials in composite matrices given the current state of development. Moreover, if the disadvantages of non-reusable adhesives are considered, the recyclability of green biocomposites is compromised. Therefore, reinforcements should be bonded and protected by other substances instead of adhesives when producing green biocomposites [89]. In the last century, plastics have been used as a matrix to produce glue-free biocomposites [90]. The thermoplasticity of plastics allows the reinforcing materials to be connected through plastic melting and resolidification when preparing biocomposites [91]. Moreover, the wear resistance and water resistance of the plastic surface can effectively protect the reinforcement inside [92]. Recycling plastic could be used as the base material to reduce petroleum resource consumption during the pretreatment and manufacturing process of wood-plastic composite materials [93]. While industrial polymers such as plastics originate from petroleum, they are still environmentally harmful when discharged and disposed of [94]. A plastic-free binder and even a petroleum-free strategy is therefore essential for sustainable and recyclable green biocomposites.

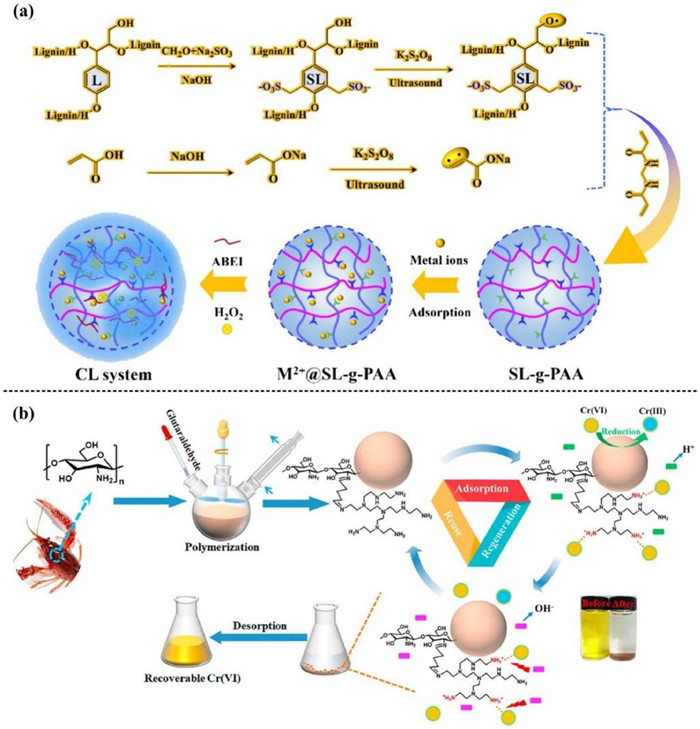

Plastic-free binder strategies enable materials to be prepared without adverse environmental effects, as well as increase product recovery rates. While biomass fillers such as lignin and chitosan can be used to link reinforcements, these connections lack strength and diversity. By manipulating the connection method and selectively modifying functional groups, the biomass substrate can improve strength and functionality (Figs. 7a and b) [95,96]. It has been proposed by Jiao et al. [96] that lignin may be used as a hydrogel substrate instead of a petroleum base and sulfomethylated to increase water solubility (Fig. 7a). Ultrasonic-assisted free radical polymerisation has also been proposed as another strategy for the synthesis of lignin-based hydrogels, which can be achieved in aqueous systems with milder reaction conditions and shorter reaction times [97]. According to Moreno et al. [98], the viability of lignin-based smart materials for novel high-performance applications may be shown, while the difficulties and possibilities for their development can be found.

Unlike fibers used as engineering materials, water-retaining fibers have been reported in the preparation of biomass hydrogels. Contrary to the method of water-repellent treatment of fibers, the hydrophobic components in the fibers, such as lignin, need to be removed during the preparation of water-retaining fibers. Exposing the free hydroxyl groups in cellulose to the external environment can effectively retain water. Kong et al. prepared water-retaining wood-based fibers from wood and combined them with polyacrylamide (PAM) polymers to create strong, anisotropic, flexible, and ionically conductive wood-based hydrogels [37].

Biocomposites can be prepared in two ways. As seen from the macroscopic perspective, the “top-down” method of directly utilising the biomass structure is a mature and low-cost technology suitable for large-scale production and utilisation. However, biomass presents structural defects that are difficult to modify with limited structure expansion, the result being that it cannot be fully qualified for applications requiring greater performance and diversification. As people become more aware of the microstructure of biomass and nanotechnology matures, “bottom-up” preparation methods are becoming increasingly popular. It is more convenient to achieve homogeneous and excellent performance using biomass materials as the base layer of composite materials.

The top-down material preparation method is to prepare composite materials by various techniques such as etching or heat treatment through substances of larger size (from micrometre to centimetre). The structure and properties of the material largely depend on the properties of the biomass used as raw materials [78,99]. This preparation method has the advantages of high precision, controllable structure, and adjustable properties and has seen widespread use in industries like electronic and optical materials [100]. Biomass can be used as a scaffold for creating composite materials by retaining their original skeleton, and this method maximises the porosity, lightweight, and specific strength of natural fibre raw materials.

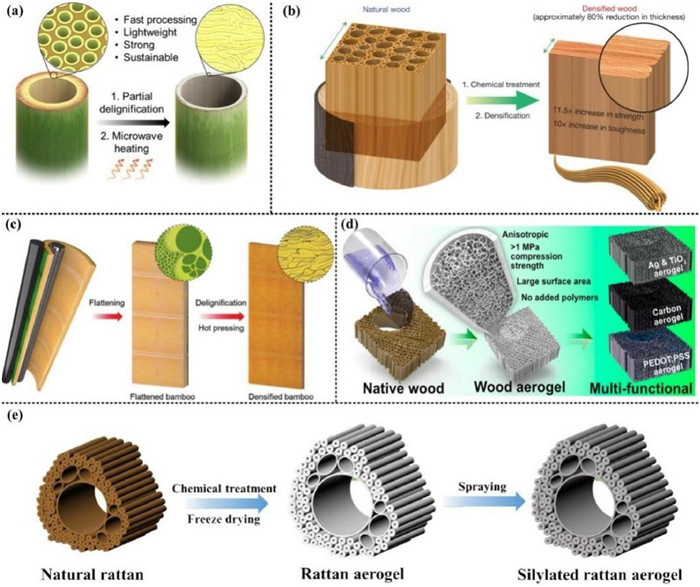

The skeletons of natural plant fibres, such as wood and bamboo, contain a great deal of amorphous cellulose and abundant hydroxyl groups, which need to be partially or completely removed in order to facilitate the modification of cellulose [101-104]. Following air drying or hot pressing, the binding inside the fibre is strengthened, thereby replacing pores and defects within natural fibres with dense clusters of fibres, covering up some defects such as hydroxyl group exposure caused by porosity as well as increasing hydrophilicity and destroying mechanical structure (Figs. 8a-c) [79,101,105]. As a result, fibres exhibit excellent mechanical properties, specific strength, and anisotropy due to an increase in their distribution of unit area [106]. Overall, this method can provide suitable materials for hydrogel or aerogel preparation owing to the extensive surface area of the preserved original fibre structure (Figs. 8d and e) [107,108].

Xia et al. proposed a method for preparing lignocellulosic bioplastics through in-situ lignin regeneration, which produced a uniform and highly viscous cellulose-lignin pulp [109]. A highly dense structure is created due to the lignin filling the micro/nano fibre space in the fibre cellulose network. Since the raw material is entirely biomass, the finished product is safely biodegradable in nature or readily recyclable [110]. Additionally, lignin with micro/nano cellulose original fibres is entangled on a nanoscale and hydrogen bonds are formed between them. The bioplastics resulted from lignocellulosic exhibit excellent water stability, high mechanical strength, improved thermal stability and UV resistance [111].

The bottom-up preparation approach produces biomass composite materials based on the microstructure of materials such as atoms, molecules, and crystalline grains, providing macroscopic structures through layer-by-layer assembly and self-assembly [112]. By contrast to traditional top-down processing methods, the bottom-up approach alters the underlying logic of the biomass in order to control the properties of the biomass and to improve its performance and scalability [113,114]. Additionally, the reconstituted biomass exhibits a higher strength and stability than biomass, making it a suitable material for various engineering purposes and functional applications [115].

The biomass scaffold constructed at the microscale has excellent performance and multifunctionality due to component alignment [116,117]. Therefore, when developing biomimetic materials, controlling the orientation of nanoparticles is crucial [118]. The mechanical, optical, and swelling properties of a material may be enhanced after the nanoparticles have been aligned successfully. Several scaffold frameworks were made from nanocellulose, and new arrangements, including porous and fibrous materials, could be obtained by altering the underlying structure of the scaffold and its layered arrangement (Fig. 9a) [30]. Since nanocellulose is anisotropic, various external forces can be used to position it, such as rotational coatings, immersion coatings, extrusion/rotation, stretching/stretching, and casting. Complex networks can be achieved by actively aligning nanofibres in a uniaxial manner using shear forces. Therefore, the “bottom-up” approach generally produces hydrogels and aerogels that have a complex structural composition, or layered fibres or films (Figs. 9b-d) [119-122]. Nanocellulose and lignin have been proposed as materials for reconstructing reinforced materials and enhancing biomaterials from the bottom up (Fig. 9e) [123]. This pure natural, biodegradable material has high water stability, low cost and excellent mechanical properties, it is therefore a promising contender for replacing plastic products.

The construction of functional composite materials can be achieved using a variety of biomass substrates as part of an ordered framework of nanofibres with various functionalities depending on the functional groups on the fibre surface, as well as the characteristics of the substrate [17,124]. An environmentally friendly, low-cost piezoelectric film was developed by Hänninen by combining chitosan with a nanofibre framework to produce a piezoelectric substrate that can be used as a sensor and energy harvester [125].

Biocomposites that are environmentally friendly and sustainable are not limited to the use of existing biomass. It is necessary to use high-performance and functional materials to obtain higher performance and broader application value as a means of replacing some high-polluting production materials. Preparation methods should be selected according to the application scenario and required performance, as well as changing their physical and chemical structures in order to cater to several uses including packaging, construction, and medicine. The functional utilization and superior performance of biomass composites is anticipated to become a significant research area as technology advances.

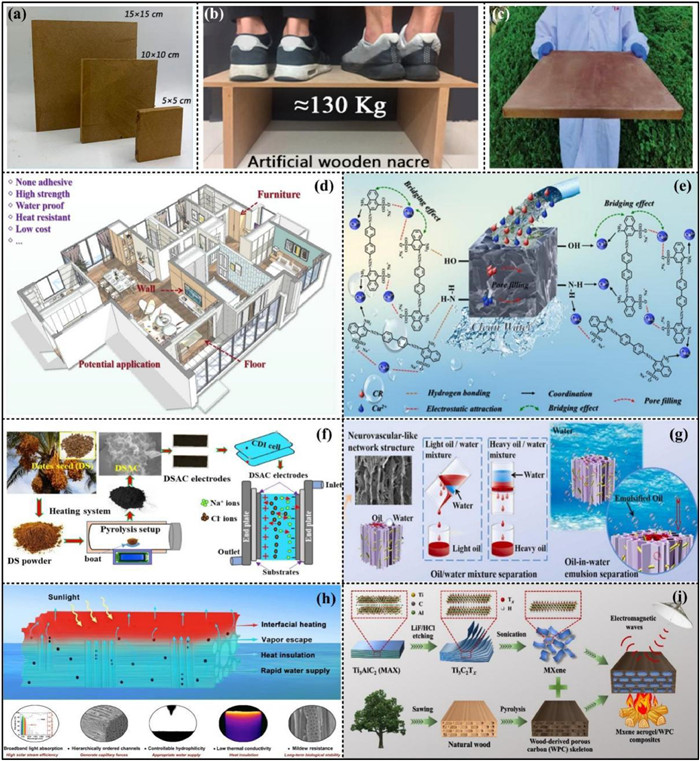

Biocomposites, such as resin-based wood-based panels like particleboard, medium-density fibreboard, and plywood, are commonly used in engineering materials [126]. However, their mechanical properties are limited and rely on petrochemical adhesives, resulting in significant pollution and non-recyclable products that do not meet the sustainability requirements of green biocomposites [127,128]. Therefore, it is imperative to introduce advanced strategies to design and manufacture new sustainable structural materials (Figs. 10a-i) [129-135]. Mechanical properties and water resistance are the primary criteria for engineering materials, while low costs are needed to meet large-scale production demands [136]. As a result, the top-down approach should be used more extensively in the preparation of engineering materials in order to reduce costs and increase output [137]. Moreover, it is pertinent not to undervalue the potential applications of bottom-up recombinant biocomposites. High-performance supports and outdoor applications are more popular due to their higher performance and greater controllability.

Despite the inherent strength of natural fibres, the density of biomass is significantly lower than its actual density due to structural defects and sparse fibre distribution. This material does not meet the usage standards of engineering materials, and its poor water resistance renders it unsuitable for wet environments [138]. To address this problem, two solutions have been proposed. One involves promoting fibre bonding through fibre improvement [139]. By blocking the interaction between surface hydroxyl groups and moisture, dense binding produces more hydrogen bonds between fibres, thus enhancing the mechanical performance of fibres per unit area [104,140]. Guan [141] embeds metal ions into wood flours by nano-etching and surface activation. The addition of metal ions strengthens the binding between fibres, making the green biocomposite material have better mechanical properties. Also, the addition of metal ions greatly increases the specific surface area, which provides a strategy for the preparation of functional engineering materials in the future.

The second method involves modifying the matrix of biocomposite materials to improve the compatibility and water resistance amongst the matrix and fibres, thereby enhancing the overall performance of the biocomposite material [142]. By filling the matrix between fibres, the modified matrix prevents water, air, and bacteria from damaging the structure of the material and connects the fibres to enhance its hardness and impact resistance. amongst the excellent biomass-based materials are chitosan, lignin, and various biomass adhesives [143]. Rath strengthened the material using chitosan and flax fibre, creating a biocomposite material with lower density but stronger performance [144]. Zhu has developed biocomposites far superior to conventional plastics by adding lignin to nanocellulose [145].

Dense biomass is not the only development direction for biocomposite materials, the naturally porous structure makes it ideal for adsorption materials [146,147]. Moreover, biomass is very suitable for functional modification due to its diverse functional groups [148]. The porous nature of biomass is also well suited to serve as attachment sites for highly adsorbent materials [149]. Ma et al. prepared magnetic WC—Co composites by carbonising ZIF-67@wood obtained by in situ growth of ZIF-67 on wood, which can effectively adsorb organic dyes in water and can be reused, which has broad application prospects in practical wastewater treatment [41]. It is possible to obtain porous cellulose gel networks by performing a top-down chemical process. It has been demonstrated that biomass hydrogels can be manufactured at a low cost due to the natural water-retaining ability of fibres [150]. In natural plant fibres, hydrophobic substances such as lignin and dense-hard cellulose crystals require proper treatment to reveal the porous and water-absorbing cellulose network [151]. Compared with the direct use of natural wood, Chao et al. selectively removed lignin and hemicellulose to prepare a highly compressible wood sponge, this improved adhesion characteristics and produced a greater specific surface area, thereby making it possible for graphene oxide to be adhered to crude oil to adsorb it [152]. The product has an essential significance in the prevention of crude oil pollution in the ocean.

It is also feasible to construct bio-based hydrogels with microstructures for adsorption. Building 3D scaffolds artificially using nanocellulose can result in higher specific surface areas and greater ease of adding other polymers for modification [153-155]. The use of green biocomposites has been extensively explored and applied as they have several advantages in recyclability and environmental friendliness compared with existing adsorbent materials prepared from petroleum-based materials [156]. Reduced graphene oxide and nano-chitosan were introduced into cellulose network aerogels to prepare hydrophobic and lipophilic adsorption aerogels [157]. Zhao et al. prepared a highly efficient adsorbent using sodium alginate and cellulose nanofibers using simple crosslinking, which is capable of efficiently adsorbing Pb(Ⅱ) in water. Since biomass fibres have a wide range of functional groups, chimaeric polymers can be easily fabricated with high stability [158].

Not only absorbing organic solvents and heavy metal ions, but also using the natural hydrophilicity of fibers to effectively prepare a new type of biomass sponge, And completely use solar thermal technology to realize interface evaporation and water resource extraction, which provides a new strategy for water resource utilization in inland areas [159]. Meng et al. extracted hydrophobic lignin from the cell wall of natural wood and combined it with MOF materials to prepare a solar-driven evaporator with a high light absorption capacity and super hydrophilicity of 5.69 kg/m2 [160,161]. Compared with other semiconductor types of solar evaporators, this natural biomass as a substrate is lower in cost and completely more environmentally friendly, without any environmental pressure, and provides help for environmental governance [162].

Electronic products from biomass materials are more environmentally friendly than traditional electronic products from plastics and glass [163,164]. Biomass contains many reactive and polar groups that can be used to prepare conductive biomaterials [163,165]. The porosity of biomass and the presence of a large number of functional groups enable polymers or conductive ions to be carried over the surface to make it conductive [166]. Conductive biomass can resist electromagnetic interference, thereby protecting high-precision electronic equipment from failure and degradation and minimising the risk of health problems. An alkaline pretreatment of bamboo cellulose fibres followed by an in situ reduction of silver nanofibers was used by Lin et al. to manufacture conductive bamboo cellulose fibers [167]. An alkaline pretreatment method can be adopted to a broad range of biomass materials, including wood fibres, and allow selective conductivity to be achieved. Gan et al. fabricated a fully recyclable EMI shielding material with high mechanical properties using the abundant lignin channels of delignified wood as conductive sites via in situ chemical vapour deposition [168].

Some biomasses offer excellent performance management capabilities due to their high dielectric constants and unique double-layer electric effects; natural plant fibres can form flexible electronic materials due to their many reactive and polar groups [169,170]. Furthermore, the toughness and flexibility of the fibre make it suitable for use in flexible electronic devices and sensors for bioimaging. Wang et al. introduced sodium ions into nanocellulose fibres to prepare a lignocellulose nanopaper with high ionic conductivity, electronic insulation, effective capacitance, transparency, and ultra-smooth surface [171]. The carboxyl and hydroxyl groups present on the cellulose surface promote the transfer of ions by absorbing water molecules, which then changes the effective dielectric constant of the film to detect the relative humidity of the environment. In another study, polyaniline was added to the cellulose/chitosan composite material, resulting in improved electrical conductivity, low voltage stress, good sensitivity, and good compression stress and strain cycle stability [172]. The product demonstrated a wide range of applications in real-time health monitoring and human motion recognition owing to its non-toxicity, biocompatibility, biodegradability, high mechanical strength and porosity.

Different from the commonly used chemical adsorption, the report of the new capacitive deionization (CDI) method is gradually increasing. This new method can be effectively used in water pollution control and seawater desalination and effectively reduces the problem of water shortage. CDI is usually performed at low voltage, applied between two electrodes that can adsorb counterions from a solution according to the principle of electric double layer (EDL). Naturally porous biomass and its derivatives have become the precursors for making this electrode adsorption material, and there have been many reports. Lu et al. used the pyrolysis of xylose mixed with KHCO3 to prepare porous carbon nanosheets from natural biomass. This low-cost and environmentally friendly novel preparation strategy also has a salt adsorption capacity of 16.29 mg/g [173]. Sheng et al. prepared nitrogenated porous carbon by pyrolysis of natural biomass containing urea as a nitrogen source in natural willow and has a natural hollow microtube structure, which makes it have good desalination ability and good cycle performance [174]. These reports provide a biomass solution for green material preparation [175].

Biomass has gained attention recently because of its sustainability and recyclability. With the development of advanced processing technology and an in-depth understanding of biomass structure, it became possible to transform abundantly available biomass materials into high-performance multifunctional biocomposites. Following are the challenges and prospects for the development of green biomass composite materials:

(1) It is imperative that biocomposites maintain their environmental protection characteristics since they are meant to replace old, highly polluting and non-recyclable materials.

(2) Existing biomass materials are limited to simple but inefficient applications such as wooden furniture and outdoor decoration, which cannot be used to rectify their shortcomings effectively. In the future, biocomposites should be modified to provide higher performance or to have additional functions that allow them to be used in wider applications.

(3) The life cycle of biocomposites needs to be regulated even though they are completely decomposable under natural conditions and environmentally friendly. When materials have a short life cycle, they cannot be used under natural conditions, and when they have a long-life cycle, they cannot decompose. Hence, the durability of green biocomposites should be designed to match the life cycle of the scenarios in which they are used.

(4) The potential of fully recyclable glue-free biocomposites for engineering applications remains limited, and a better method is required to produce materials from biomass through a fully recyclable preparation process.

(5) In terms of applying adsorption materials, modification to increase the adsorption effect is necessary, but the current adsorption and complicated preparation methods hinder the application of green biosorption materials. Broader adsorption selectivity and simpler preparation process are the development direction of green biosorbent materials.

(6) Although biomass-based “green” electronics have made significant progress at the fundamental research level, major bottlenecks remain to be resolved before these technologies can be widely adopted. Nevertheless, the uncertainty of biomass structure and the low degree of electrical conductivity remain problems to be resolved. New strategies are required to achieve more precise control of the structure and molecular size of biomass materials, as well as the design of special molecular domains and device structures to improve their performance further.

Therefore, the preparation of green biocomposites requires biomass as the basic material, and plant fibre as the main source may be a good method. Other reinforcing materials can increase functionality through a large number of active groups in the biomass itself or as attachment sites, suitable additives are crucial, not only do not destroy the recyclability of the biomass itself, but also endow the material with more functions. The mechanical properties of the material itself depend on the combination of the fibers themselves, so improving the compatibility and combination of fibers may be one of the strategies to enhance the mechanical properties.

This review provides an overview of recent green biocomposites that have received significant attention for their recyclability and degradability. Development, composition, preparation methods, and current applications of green biocomposites are discussed, as well as their challenges and prospects. As raw materials for green biocomposites are widely available and have a high yield, they are cost-effective and could be produced and utilised on a large scale. Top-down and bottom-up methods can be used to prepare consumer-grade materials with high yields and low costs as well as enterprise-grade materials with high performance and precision. Various applications of green biocomposites have been highlighted in the article, including engineering, adsorption, and conductive materials, due to their inherent characteristics, such as natural porosity, high specific strength, diversity of functional groups, and high reactivity. amongst the trends in future materials development will be high-efficiency adsorbents, low-cost engineering materials without formaldehyde emissions, and green conductive materials. Moreover, green biocomposites are environmentally friendly and can partially replace non-renewable and highly polluting materials. The use of these materials can effectively reduce their environmental impact and encourage the practice of green production and living. In conclusion, green biocomposites have broad application prospects. Future technology will result in a greater variety of application scenarios, a wide distribution throughout society, and a greater generation of economic and social benefits.

The authors declare no conflict of interest.

The authors thank the National Natural Science Foundation of China (No. 32201491), China Postdoctoral Science Foundation (No. 2021M690847), Natural Science Foundation of Jiangsu Province (No. BK20200775), Natural Science Foundation of the Jiangsu Higher Education Institutions of China (No. 21KJB220011), Science and Technology Innovation Program of Hunan Province (No. 2021RC2106), Deputy General Project of Science and Technology of Jiangsu Province (No. FZ20211507), Hunan Province Biomass-based Materials Green and Low-carbon Intelligent Manufacturing Engineering Technology Research centre (No. 2022TP2033), and Technology centre of Hunan Hongsen Novel Material Technology Co., Ltd. (No. HNJSZX2022290).

Supplementary material associated with this article can be found, in the online version, at doi:

B. Li, G. Zhao, G. Wang, et al., Adv. Sustain. Syst. 5 (2021) 2000295.

doi: 10.1002/adsu.202000295

B. Barkia, P. Aubry, P. Haghi-Ashtiani, et al., J. Mater. Sci. Technol. 41 (2020) 209–218.

doi: 10.1016/j.jmst.2019.09.017

R. Mori, RSC Sustain. 1 (2023) 179–212.

doi: 10.1039/d2su00014h

S. Kalisz, K. Kibort, J. Mioduska, M. Lieder, A. Małachowska, J. Environ. Manage. 304 (2022) 114239.

doi: 10.1016/j.jenvman.2021.114239

A.Z. Naser, I. Deiab, B.M. Darras, RSC adv. 11 (2021) 17151–17196.

doi: 10.1039/d1ra02390j

H. Han, J. Sustain. Tour. 29 (2021) 1021–1042.

doi: 10.1080/09669582.2021.1903019

Z. Wang, Prog. Polym. Sci. 101 (2020) 101197.

doi: 10.1016/j.progpolymsci.2019.101197

Q. Ou, B. Yang, J. Zhang, et al., Small 17 (2021) 2007241.

doi: 10.1002/smll.202007241

S. Vigneshwaran, R. Sundarakannan, K. John, et al., J. Clean. Prod. 277 (2020) 124109.

doi: 10.1016/j.jclepro.2020.124109

J. Deng, Q. Song, S. Liu, et al., Compos. B: Eng. 245 (2022) 110221.

doi: 10.1016/j.compositesb.2022.110221

M. Ramesh, Prog. Mater. Sci. 102 (2019) 109–166.

doi: 10.1016/j.pmatsci.2018.12.004

N. Forintos, T. Czigany, Compos. B 162 (2019) 331–343.

doi: 10.1016/j.compositesb.2018.10.098

B. Kumar, S. Roy, D.O. Agumba, D.H. Pham, J. Kim, Int. J. Biol. Macromol. 222 (2022) 1304–1313.

doi: 10.1016/j.ijbiomac.2022.09.237

F.A. Gonçalves, M. Santos, T. Cernadas, P. Ferreira, P. Alves, Int. Mater. Rev. 67 (2022) 119–149.

doi: 10.1080/09506608.2021.1915936

A. Yadav, N. Bagotia, A.K. Sharma, S. Kumar, Sci. Total Environ. 784 (2021) 147108.

doi: 10.1016/j.scitotenv.2021.147108

T. Raj, K. Chandrasekhar, A.N. Kumar, S.H. Kim, Renew. Sust. Energ. Rev. 158 (2022) 112130.

doi: 10.1016/j.rser.2022.112130

C. Zhang, J. Mo, Q. Fu, et al., Nano Energy 81 (2021) 105637.

doi: 10.1016/j.nanoen.2020.105637

X. Tang, D. Liu, Y.J. Wang, et al., Prog. Mater. Sci. 118 (2021) 100770.

doi: 10.1016/j.pmatsci.2020.100770

A. Vinod, M. Sanjay, S. Suchart, P. Jyotishkumar, J. Clean. Prod. 258 (2020) 120978.

doi: 10.1016/j.jclepro.2020.120978

Y. Liu, S. Ahmed, D.E. Sameen, et al., Trends Food Sci. Technol. 112 (2021) 532–546.

doi: 10.1016/j.tifs.2021.04.016

P. Luan, X. Zhao, K. Copenhaver, S. Ozcan, H. Zhu, Adv. Fiber Mater. 4 (2022) 736–757.

doi: 10.1007/s42765-022-00151-w

W. Fan, Y. Zhang, Y. Sun, et al., Chem. Eng. J. 455 (2023) 140917.

doi: 10.1016/j.cej.2022.140917

X. Hou, S. Liu, C. He, J. Mater. Chem. A 10 (2022) 1497–1505.

doi: 10.1039/d1ta09128j

O.M. Atta, S. Manan, A. Shahzad, et al., Food Hydrocoll 125 (2022) 107419.

doi: 10.1016/j.foodhyd.2021.107419

X. Zhao, Y. Wang, X. Chen, et al., Matter 6 (2023) 97–127.

doi: 10.1117/12.2686941

Y. Xiao, W. Wang, X. Tian, et al., Research 2020 (2020) 12–17.

doi: 10.1002/j.2769-2795.2020.tb00047.x

R. Mohammadinejad, H. Maleki, E. Larraneta, et al., Appl. Mater. Today 16 (2019) 213–246.

doi: 10.1016/j.apmt.2019.04.010

W. Li, L.S. Mille, J.A. Robledo, et al., Adv. Healthc. Mater. 9 (2020) 2000156.

doi: 10.1002/adhm.202000156

X. Tan, Y. Wang, W. Du, T. Mu, ChemSusChem 13 (2020) 321–327.

doi: 10.1002/cssc.201902979

K. De France, Z. Zeng, T. Wu, G. Nyström, Adv. Mater. 33 (2021) 2000657.

doi: 10.1002/adma.202000657

Y. Luo, Y. Miao, H. Wang, et al., Nano Res. 16 (2023) 7600–7608.

doi: 10.1007/s12274-023-5382-y

W. Fan, C. Zhang, Y. Liu, et al., Nano Res. 16 (2023) 1–9.

doi: 10.1007/s12274-022-5053-4

H. Ye, J. Jiang, Y. Yang, et al., Adv. Compos. Hybrid Mater. 6 (2023) 81.

doi: 10.1007/s42114-023-00664-x

R. Ilyas, M. Zuhri, M.N.F. Norrrahim, et al., Polymers 14 (2022) 182.

doi: 10.3390/polym14010182

H. Ye, Y. Wang, Q. Yu, et al., Chemosphere 287 (2022) 132436.

doi: 10.1016/j.chemosphere.2021.132436

C. Chen, Y. Zhang, Y. Li, et al., Energy Environ. Sci. 10 (2017) 538–545.

doi: 10.1039/C6EE03716J

W. Kong, C. Wang, C. Jia, et al., Adv. Mater. 30 (2018) 1801934.

doi: 10.1002/adma.201801934

P. Zheng, N. Chen, S. Mahfuzul Islam, et al., ACS Sustain. Chem. Eng. 7 (2018) 3909–3916.

H. Sun, Z. Ren, T. Ji, H. Bi, M. Xu, J. Mater. Res. Technol. 14 (2021) 3043–3050.

doi: 10.1016/j.jmrt.2021.08.153

C. Chen, Y. Wang, Q. Wu, et al., Chem. Eng. J. 400 (2020) 125876.

doi: 10.1016/j.cej.2020.125876

X. Ma, S. Zhao, Z. Tian, et al., Chem. Eng. J. 446 (2022) 136851.

doi: 10.1016/j.cej.2022.136851

H. Ye, G. Zheng, S. Zuo, et al., Appl. Surf. Sci. 615 (2023) 156313.

doi: 10.1016/j.apsusc.2022.156313

Z. Wang, Y. Yu, K. Roy, C. Gao, L. Huang, MDPI 20 (2023) 1871.

E. Zini, M. Scandola, Polym. Compos. 32 (2011) 1905–1915.

doi: 10.1002/pc.21224

G.S. Mann, L.P. Singh, P. Kumar, S. Singh, Compos. Mater. 33 (2020) 1145–1171.

doi: 10.1177/0892705718816354

M. Zhang, G.M. Biesold, W. Choi, et al., Mater. Today 53 (2022) 134–161.

doi: 10.1016/j.mattod.2022.01.022

X. Bi, M. Li, G. Zhou, et al., Nano Res. 12 (2023) 1–14.

R. Ilyas, M. Zuhri, H. Aisyah, et al., Polymers 14 (2022) 202.

doi: 10.3390/polym14010202

S. Amiandamhen, M. Meincken, L. Tyhoda, Fibers Polym. 21 (2020) 677–689.

doi: 10.1007/s12221-020-9362-5

M. Asrofi, E. Syafri, S. Sapuan, R. Ilyas, Key Eng. Mater. 849 (2020) 96–101.

doi: 10.4028/www.scientific.net/kem.849.96

W. Sun, M. Tajvidi, C.G. Hunt, et al., J. Clean. Prod. 353 (2022) 131659.

doi: 10.1016/j.jclepro.2022.131659

T.D. Tavares, J.C. Antunes, F. Ferreira, H.P. Felgueiras, Biomolecules 10 (2020) 148.

doi: 10.3390/biom10010148

K. Rafiee, H. Schritt, D. Pleissner, G. Kaur, S.K. Brar, Curr. Opin. Green Sustain. Chem. 30 (2021) 100482.

doi: 10.1016/j.cogsc.2021.100482

M.J. John, R.D. Anandjiwala, Polym. Compos. 29 (2008) 187–207.

doi: 10.1002/pc.20461

M. Mohammed, R. Rahman, A.M. Mohammed, et al., Polym. Test. 115 (2022) 107707.

doi: 10.1016/j.polymertesting.2022.107707

Y. Liang, G. Zheng, C. Xia, et al., J. Clean. Prod. 351 (2022) 131531.

doi: 10.1016/j.jclepro.2022.131531

S. Kalia, K. Thakur, A. Celli, M.A. Kiechel, C.L. Schauer, J. Environ. Chem. Eng. 1 (2013) 97–112.

doi: 10.1016/j.jece.2013.04.009

J. Manivannan, S. Rajesh, K. Mayandi, et al., J. Nat. Fibers 19 (2022) 4007–4023.

doi: 10.1080/15440478.2020.1848743

S. Bousshine, M. Ouakarrouch, A. Bybi, et al., Appl. Acoust. 187 (2022) 108520.

doi: 10.1016/j.apacoust.2021.108520

H.S. Shekar, M. Ramachandra, Mater. Today Proc. 5 (2018) 2518–2526.

doi: 10.1016/j.matpr.2017.11.034

Z. Zhang, S. Cai, Y. Li, et al., Compos. Sci. Technol. 194 (2020) 108151.

doi: 10.1016/j.compscitech.2020.108151

Y. Leow, V. Sequerah, Y.C. Tan, et al., Compos. B: Eng. 241 (2022) 110031.

doi: 10.1016/j.compositesb.2022.110031

S. Alsubari, M. Zuhri, S. Sapuan, et al., Polymers 13 (2021) 423.

doi: 10.3390/polym13030423

L. Zhao, S. Pan, N. Holzmann, P. Schwerdtfeger, G. Frenking, Chem. Rev. 119 (2019) 8781–8845.

doi: 10.1021/acs.chemrev.8b00722

D. Zhao, M. Feng, L. Zhang, et al., Carbohydr. Polym. 256 (2021) 117580.

doi: 10.1016/j.carbpol.2020.117580

S. Godara, Mater. Today Proc. 18 (2019) 3428–3434.

doi: 10.1016/j.matpr.2019.07.270

Y.L. Loow, T.Y. Wu, J. Md. Jahim, A.W. Mohammad, W.H. Teoh, Cellulose 23 (2016) 1491–1520.

doi: 10.1007/s10570-016-0936-8

C. Huang, Y. Zhan, J. Wang, et al., Green Chem. 24 (2022) 3736–3749.

doi: 10.1039/d2gc00301e

G. Zheng, H. Ye, Y. Liang, et al., Constr. Build. Mater. 367 (2023) 130350.

doi: 10.1016/j.conbuildmat.2023.130350

R. Vijay, D.L. Singaravelu, A. Vinod, et al., Int. J. Biol. Macromol. 125 (2019) 99–108.

doi: 10.1016/j.ijbiomac.2018.12.056

M. Beg, K. Pickering, Mater. Manuf. Proc. 21 (2006) 303–307.

doi: 10.1080/10426910500464750

M.N. Izani, M. Paridah, U. Anwar, M.M. Nor, P. H’ng, Compos. B: Eng. 45 (2013) 1251–1257.

doi: 10.1016/j.compositesb.2012.07.027

W. Lv, Z. Xia, Y. Song, et al., Ind. Crops. Prod. 171 (2021) 113934.

doi: 10.1016/j.indcrop.2021.113934

J. He, C. Huang, C. Lai, et al., Ind. Crops. Prod. 146 (2020) 112205.

doi: 10.1016/j.indcrop.2020.112205

E.S. Ferreira, E.D. Cranston, C.A. Rezende, ACS Sustain. Chem. Eng. 8 (2020) 8267–8278.

doi: 10.1021/acssuschemeng.0c01480

S. Ma, Y. Yan, C. He, et al., Ind. Crops. Prod. 180 (2022) 114712.

doi: 10.1016/j.indcrop.2022.114712

R. Yang, Q. Cao, Y. Liang, et al., Chem. Eng. J. 401 (2020) 126150.

doi: 10.1016/j.cej.2020.126150

Z. Li, C. Chen, H. Xie, et al., Nat. Sustain. 5 (2022) 235–244.

J. Song, C. Chen, S. Zhu, et al., Nature 554 (2018) 224–228.

doi: 10.1038/nature25476

X. Lv, J. Han, M. Liu, et al., Chem. Eng. J. 452 (2022) 139439.

M.H. Mohamed, I.A. Udoetok, L.D. Wilson, Compos. Sci. Technol. 4 (2020) 15.

T.V. Thanh, L.T. Hao, H.Y. Cho, et al., ACS Sustain. Chem. Eng. 10 (2022) 8411–8422.

doi: 10.1021/acssuschemeng.2c01395

C. Calvino, N. Macke, R. Kato, S.J. Rowan, Prog. Polym. Sci. 103 (2020) 101221.

doi: 10.1016/j.progpolymsci.2020.101221

C. Gilbert, T.C. Tang, W. Ott, et al., Nat. Mater. 20 (2021) 691–700.

doi: 10.1038/s41563-020-00857-5

Y. Wan, P. Xiong, J. Liu, et al., ACS Nano 15 (2021) 8439–8449.

doi: 10.1021/acsnano.0c10666

C. Li, H. Lei, Z. Wu, et al., ACS Appl. Mater. Interfaces 14 (2022) 23859–23867.

doi: 10.1021/acsami.2c02859

J. Zhang, C. Long, X. Zhang, et al., Chem. Eng. J. 450 (2022) 138387.

doi: 10.1016/j.cej.2022.138387

M. Bai, J. Cao, J. Li, C. Li, J. Clean. Prod. 321 (2021) 129001.

doi: 10.1016/j.jclepro.2021.129001

P.P. Das, V. Chaudhary, S. Mishra, Composite materials: properties, fabrication and applications, in: B. Sharma, P. Jain (Eds.), Graphene Based Biopolymer Nanocomposites, Springer, Singapore, 2021, pp. 1–24.

A. Vedrtnam, S. Kumar, S. Chaturvedi, Compos. B: Eng. 176 (2019) 107282.

doi: 10.1016/j.compositesb.2019.107282

F. Erchiqui, H. Kaddami, G. Dituba-Ngoma, F. Slaoui-Hasnaoui, Int. J. Heat Mass Transf. 158 (2020) 119996.

doi: 10.1016/j.ijheatmasstransfer.2020.119996

D. Basalp, F. Tihminlioglu, S.C. Sofuoglu, F. Inal, A. Sofuoglu, Waste Biomass Valori. 11 (2020) 5419–5430.

doi: 10.1007/s12649-020-00986-7

A.H. Elsheikh, H. Panchal, S. Shanmugan, et al., Clean Technol. Environ. Policy 8 (2022) 100450.

doi: 10.1016/j.clet.2022.100450

Y. Zhou, P. Stanchev, E. Katsou, S. Awad, M. Fan, Waste Manage. 99 (2019) 42–48.

doi: 10.1117/12.2523386

S. Han, X. Zhou, H. Xie, et al., Chemosphere 305 (2022) 135486.

doi: 10.1016/j.chemosphere.2022.135486

G.J. Jiao, J. Ma, Y. Li, et al., J. Hazard. Mater. 421 (2022) 126722.

doi: 10.1016/j.jhazmat.2021.126722

Q. Wang, X. Pan, C. Lin, et al., Chem. Eng. J. 370 (2019) 1039–1047.

doi: 10.3390/f10111039

A. Moreno, M.H. Sipponen, Mater. Horizons 7 (2020) 2237–2257.

doi: 10.1039/d0mh00798f

W. Huang, S. Ling, C. Li, F.G. Omenetto, D.L. Kaplan, Chem. Soc. Rev. 47 (2018) 6486–6504.

doi: 10.1039/C8CS00187A

J. Deng, M. Li, Y. Wang, Green Chem. 18 (2016) 4824–4854.

doi: 10.1039/C6GC01172A

Z. Li, C. Chen, R. Mi, et al., Adv. Mater. 32 (2020) 1906308.

doi: 10.1002/adma.201906308

S. Xiao, C. Chen, Q. Xia, et al., Science 374 (2021) 465–471.

doi: 10.1126/science.abg9556

A.Le Duigou, D. Correa, M. Ueda, R. Matsuzaki, M. Castro, Mater. Des. 194 (2020) 108911.

doi: 10.1016/j.matdes.2020.108911

U. Ray, S. Zhu, Z. Pang, T. Li, Adv. Mater. 33 (2021) 2002504.

doi: 10.1002/adma.202002504

C. Chen, Z. Li, R. Mi, et al., ACS Nano 14 (2020) 5194–5202.

doi: 10.1021/acsnano.9b08747

N. Van de Werken, H. Tekinalp, P. Khanbolouki, et al., Adv. Mater. 31 (2020) 100962.

J. Garemark, X. Yang, X. Sheng, et al., ACS Nano 14 (2020) 7111–7120.

doi: 10.1021/acsnano.0c01888

X. Han, W. Wu, Z. Tian, et al., Compos. Commun. 33 (2022) 101199.

doi: 10.1016/j.coco.2022.101199

Q. Xia, C. Chen, Y. Yao, et al., Nat. Sustain. 4 (2021) 627–635.

doi: 10.1038/s41893-021-00702-w

S. Gao, Z. Cheng, X. Zhou, et al., Chem. Eng. J. 394 (2020) 124896.

doi: 10.1016/j.cej.2020.124896

Y. Wang, Z. Li, D. Yang, et al., Nat. Sustain. 583 (2021) 80–88.

Y. Gong, L. Xie, C. Chen, et al., Prog. Mater. Sci. 132 (2022) 101048.

E. Guzman, R.G. Rubio, F. Ortega, Adv. Colloid Interface Sci. 282 (2020) 102197.

doi: 10.1016/j.cis.2020.102197

M. Lian, Y. Huang, Y. Liu, et al., Adv. Compos. Hybrid Mater. 5 (2022) 1612–1657.

doi: 10.1007/s42114-022-00475-6

Z. Bi, Q. Kong, Y. Cao, et al., J. Mater. Chem. A 7 (2019) 16028–16045.

doi: 10.1039/c9ta04436a

R. Brandes, D. Belosinschi, F. Brouillette, B. Chabot, J. Environ. Chem. Eng. 7 (2019) 103477.

doi: 10.1016/j.jece.2019.103477

B. Thomas, M.C. Raj, J. Joy, et al., Chem. Rev. 118 (2018) 11575–11625.

doi: 10.1021/acs.chemrev.7b00627

P. Phanthong, P. Reubroycharoen, X. Hao, et al., Energy Convers. Manag. 1 (2018) 32–43.

C. Chen, L. Berglund, I. Burgert, L. Hu, Adv. Mater. 33 (2021) 2006207.

doi: 10.1002/adma.202006207

E.J. Foster, R.J. Moon, U.P. Agarwal, et al., Chem. Soc. Rev. 47 (2018) 2609–2679.

doi: 10.1039/c6cs00895j

D.Y. Liu, G. Sui, D. Bhattacharyya, Compos. Sci. Technol. 99 (2014) 31–36.

doi: 10.1201/b16752-6

C. Zheng, K. Lu, Y. Lu, et al., Carbohydr. Polym. 250 (2020) 116905.

doi: 10.1016/j.carbpol.2020.116905

X. Wang, Q. Xia, S. Jing, et al., Small 17 (2021) 2008011.

doi: 10.1002/smll.202008011

M.E. Lamm, K. Li, J. Qian, et al., Adv. Mater. 33 (2021) 2005538.

doi: 10.1002/adma.202005538

A. Hänninen, E. Sarlin, I. Lyyra, et al., Carbohydr. Polym. 202 (2018) 418–424.

doi: 10.1016/j.carbpol.2018.09.001

A. Dorieh, M.F. Pour, S.G. Movahed, et al., Prog. Org. Coat. 165 (2022) 106768.

doi: 10.1016/j.porgcoat.2022.106768

S. Gerassimidou, O.V. Martin, S.P. Chapman, J.N. Hahladakis, E. Iacovidou, J. Clean. Prod. 286 (2021) 125378.

doi: 10.1016/j.jclepro.2020.125378

A.T. Adeleye, C.K. Odoh, O.C. Enudi, et al., Proc. Biochem. 96 (2020) 174–193.

doi: 10.1016/j.procbio.2020.05.032

Y. Chen, J. Fu, B. Dang, et al., ACS Nano 14 (2020) 2036–2043.

doi: 10.1021/acsnano.9b08647

Y. Yang, Y. Ren, S. Ge, et al., Appl. Surf. Sci. 606 (2022) 154595.

doi: 10.1016/j.apsusc.2022.154595

Y. Liu, Y. Ke, Q. Shang, et al., Chem. Eng. J. 451 (2023) 138934.

doi: 10.1016/j.cej.2022.138934

A. Hai, G. Bharath, K.R. Babu, et al., Process Saf. Environ. Prot. 129 (2019) 103–111.

doi: 10.1016/j.psep.2019.06.024

N. Tian, S. Wu, G. Han, et al., J. Hazard. Mater. 424 (2022) 127393.

doi: 10.1016/j.jhazmat.2021.127393

T. Meng, B. Jiang, Z. Li, et al., Nano Energy 87 (2021) 106146.

doi: 10.1016/j.nanoen.2021.106146

C. Liang, H. Qiu, P. Song, et al., Sci. Bull. 65 (2020) 616–622.

doi: 10.1016/j.scib.2020.02.009

K. Petersen, P.V. Nielsen, G. Bertelsen, et al., Trends Food Sci. Technol. 10 (1999) 52–68.

doi: 10.1016/S0924-2244(99)00019-9

A. Biswas, I.S. Bayer, A.S. Biris, et al., Adv. Colloid Interface Sci. 170 (2012) 2–27.

doi: 10.1016/j.cis.2011.11.001

X. Li, M. Younas, M. Rezakazemi, Q.V. Ly, J. Li, Chin. Chem. Lett. 33 (2022) 3594–3602.

doi: 10.1016/j.cclet.2021.10.044

J. Ma, J. He, X. Kong, et al., Chin. Chem. Lett. 34 (2022) 107407.

N. Mittal, F. Ansari, K. Gowda, et al., ACS Nano 12 (2018) 6378–6388.

doi: 10.1021/acsnano.8b01084

Q.F. Guan, Z.M. Han, H.B. Yang, Z.C. Ling, S.H. Yu, Natl. Sci. Rev. 8 (2021) nwaa230.

doi: 10.1093/nsr/nwaa230

L. Liu, H. Li, A. Lazzaretto, et al., Renew. Sust. Energ. Rev. 69 (2017) 912–932.

doi: 10.1016/j.rser.2016.11.140

N.A. Nguyen, C.C. Bowland, A.K. Naskar, Appl. Mater. Today 12 (2018) 138–152.

doi: 10.1016/j.apmt.2018.03.009

A. Rath, B. Grisin, T.D. Pallicity, et al., Compos. Sci. Technol. 235 (2023) 109952.

doi: 10.1016/j.compscitech.2023.109952

Z. Zhu, W. Wang, Z. Liu, et al., Ind. Crops. Prod. 185 (2022) 115106.

doi: 10.1016/j.indcrop.2022.115106

C.B. Godiya, L.A.M. Ruotolo, W. Cai, J. Mater. Chem. A 8 (2020) 21585–21612.

doi: 10.1039/d0ta07028a

X. Huang, Y. Liu, X. Wang, et al., Int. J. Env. Pub. he. 19 (2022) 10897.

doi: 10.3390/ijerph191710897

S. Liu, X. Tian, X. Zhang, et al., Chin. Chem. Lett. 33 (2022) 2205–2211.

doi: 10.1016/j.cclet.2021.09.063

P. Mei, R. Wu, S. Shi, et al., Chem. Eng. J. 420 (2021) 130382.

doi: 10.1016/j.cej.2021.130382

Y. Hu, M. Shi, L. Liu, J. Yu, Y. Fan, Int. J. Biol. Macromol. 174 (2021) 162–174.

doi: 10.1016/j.ijbiomac.2021.01.159

G. Chen, T. Li, C. Chen, et al., ACS Nano 15 (2021) 11244–11252.

doi: 10.1021/acsnano.0c10117

W. Chao, S. Wang, Y. Li, et al., Chem. Eng. J. 400 (2020) 125865.

doi: 10.1016/j.cej.2020.125865

Y. Zhang, W. Cui, W. An, et al., Appl. Catal. B 221 (2018) 36–46.

doi: 10.1016/j.apcatb.2017.08.076

L. Huang, X. Huang, J. Yan, et al., J. Hazard. Mater. 442 (2023) 130024.

doi: 10.1016/j.jhazmat.2022.130024

M. Ghazaie, M. Ghiaci, S. Soleimanian Zad, S. Behzadi Teshnizi, J. Hazard. Mater. 371 (2019) 224–232.

doi: 10.1016/j.jhazmat.2019.03.003

H.D. Thi, S.Y. Kim, S.Y. Jung, et al., SSRN 31 (2023) 4394136.

H. Gu, C. Gao, X. Zhou, et al., Adv. Compos. Hybrid Mater. 4 (2021) 459–468.

doi: 10.1007/s42114-021-00289-y

H. Zhao, X.K. Ouyang, L.Y. Yang, J. Mol. Liq. 324 (2021) 115122.

doi: 10.1016/j.molliq.2020.115122

C.C. Wang, X. Wang, W. Liu, Chem. Eng. J. 391 (2020) 123601.

doi: 10.1016/j.cej.2019.123601

T. Meng, Z. Li, Z. Wan, et al., Chem. Eng. J. 452 (2023) 139193.

doi: 10.1016/j.cej.2022.139193

X. Niu, X. Li, Z. Lyu, et al., ChemComm 56 (2020) 11338–11353.

doi: 10.1039/d0cc04890a

W. Zhu, R. Michalsky, O.n. Metin, et al., J. Am. Chem. Soc. 135 (2013) 16833–16836.

doi: 10.1021/ja409445p

Z. Su, Y. Yang, Q. Huang, et al., Prog. Mater. Sci. 125 (2022) 100917.

doi: 10.1016/j.pmatsci.2021.100917

Z.U. Arif, M.Y. Khalid, M.F. Sheikh, A. Zolfagharian, M. Bodaghi, J. Environ. Chem. Eng. 10 (2022) 108159.

doi: 10.1016/j.jece.2022.108159

T. Wu, Y. Song, Z. Shi, et al., Nano Energy 80 (2021) 105541.

doi: 10.1016/j.nanoen.2020.105541

S.Y. Lu, M. Jin, Y. Zhang, et al., Adv. Energy Mater. 8 (2018) 1702545.

doi: 10.1002/aenm.201702545

Q. Lin, S. Liu, X. Wang, Y. Huang, W. Yu, Appl. Surf. Sci. 575 (2022) 151700.

doi: 10.1016/j.apsusc.2021.151700

W. Gan, C. Chen, M. Giroux, et al., Chem. Mater. 32 (2020) 5280–5289.

doi: 10.1021/acs.chemmater.0c01507

L. Gu, J. Han, M. Chen, et al., Energy Stor. Mater. 52 (2022) 547–561.

X. Han, W. Zhou, M. Chen, et al., J. Energy Chem. 67 (2022) 727–735.

doi: 10.1016/j.jechem.2021.11.021

Y. Wang, S. Hou, T. Li, et al., ACS Appl. Mater. Interfaces 12 (2020) 41896–41904.

doi: 10.1021/acsami.0c12868

J. Huang, D. Li, M. Zhao, et al., Chem. Eng. J. 373 (2019) 1357–1366.

doi: 10.1016/j.cej.2019.05.136

T. Lu, Y. Liu, X. Xu, et al., Sep. Purif. Technol. 256 (2021) 117771.

doi: 10.1016/j.seppur.2020.117771

X. Sheng, X. Xu, Y. Wu, et al., Bull. Chem. Soc. Jpn. 94 (2021) 1645–1650.

doi: 10.1246/bcsj.20210029

C.C. Wang, J.R. Li, X.L. Lv, Y.Q. Zhang, G. Guo, Energy Environ. Sci. 7 (2014) 2831–2867.

doi: 10.1039/C4EE01299B

B. Li, G. Zhao, G. Wang, et al., Adv. Sustain. Syst. 5 (2021) 2000295.

doi: 10.1002/adsu.202000295

B. Barkia, P. Aubry, P. Haghi-Ashtiani, et al., J. Mater. Sci. Technol. 41 (2020) 209–218.

doi: 10.1016/j.jmst.2019.09.017

R. Mori, RSC Sustain. 1 (2023) 179–212.

doi: 10.1039/d2su00014h

S. Kalisz, K. Kibort, J. Mioduska, M. Lieder, A. Małachowska, J. Environ. Manage. 304 (2022) 114239.

doi: 10.1016/j.jenvman.2021.114239

A.Z. Naser, I. Deiab, B.M. Darras, RSC adv. 11 (2021) 17151–17196.

doi: 10.1039/d1ra02390j

H. Han, J. Sustain. Tour. 29 (2021) 1021–1042.

doi: 10.1080/09669582.2021.1903019

Z. Wang, Prog. Polym. Sci. 101 (2020) 101197.

doi: 10.1016/j.progpolymsci.2019.101197

Q. Ou, B. Yang, J. Zhang, et al., Small 17 (2021) 2007241.

doi: 10.1002/smll.202007241

S. Vigneshwaran, R. Sundarakannan, K. John, et al., J. Clean. Prod. 277 (2020) 124109.

doi: 10.1016/j.jclepro.2020.124109

J. Deng, Q. Song, S. Liu, et al., Compos. B: Eng. 245 (2022) 110221.

doi: 10.1016/j.compositesb.2022.110221

M. Ramesh, Prog. Mater. Sci. 102 (2019) 109–166.

doi: 10.1016/j.pmatsci.2018.12.004

N. Forintos, T. Czigany, Compos. B 162 (2019) 331–343.

doi: 10.1016/j.compositesb.2018.10.098

B. Kumar, S. Roy, D.O. Agumba, D.H. Pham, J. Kim, Int. J. Biol. Macromol. 222 (2022) 1304–1313.

doi: 10.1016/j.ijbiomac.2022.09.237

F.A. Gonçalves, M. Santos, T. Cernadas, P. Ferreira, P. Alves, Int. Mater. Rev. 67 (2022) 119–149.

doi: 10.1080/09506608.2021.1915936

A. Yadav, N. Bagotia, A.K. Sharma, S. Kumar, Sci. Total Environ. 784 (2021) 147108.

doi: 10.1016/j.scitotenv.2021.147108

T. Raj, K. Chandrasekhar, A.N. Kumar, S.H. Kim, Renew. Sust. Energ. Rev. 158 (2022) 112130.

doi: 10.1016/j.rser.2022.112130

C. Zhang, J. Mo, Q. Fu, et al., Nano Energy 81 (2021) 105637.

doi: 10.1016/j.nanoen.2020.105637

X. Tang, D. Liu, Y.J. Wang, et al., Prog. Mater. Sci. 118 (2021) 100770.

doi: 10.1016/j.pmatsci.2020.100770

A. Vinod, M. Sanjay, S. Suchart, P. Jyotishkumar, J. Clean. Prod. 258 (2020) 120978.

doi: 10.1016/j.jclepro.2020.120978

Y. Liu, S. Ahmed, D.E. Sameen, et al., Trends Food Sci. Technol. 112 (2021) 532–546.

doi: 10.1016/j.tifs.2021.04.016

P. Luan, X. Zhao, K. Copenhaver, S. Ozcan, H. Zhu, Adv. Fiber Mater. 4 (2022) 736–757.

doi: 10.1007/s42765-022-00151-w

W. Fan, Y. Zhang, Y. Sun, et al., Chem. Eng. J. 455 (2023) 140917.

doi: 10.1016/j.cej.2022.140917

X. Hou, S. Liu, C. He, J. Mater. Chem. A 10 (2022) 1497–1505.

doi: 10.1039/d1ta09128j

O.M. Atta, S. Manan, A. Shahzad, et al., Food Hydrocoll 125 (2022) 107419.

doi: 10.1016/j.foodhyd.2021.107419

X. Zhao, Y. Wang, X. Chen, et al., Matter 6 (2023) 97–127.

doi: 10.1117/12.2686941

Y. Xiao, W. Wang, X. Tian, et al., Research 2020 (2020) 12–17.

doi: 10.1002/j.2769-2795.2020.tb00047.x

R. Mohammadinejad, H. Maleki, E. Larraneta, et al., Appl. Mater. Today 16 (2019) 213–246.

doi: 10.1016/j.apmt.2019.04.010

W. Li, L.S. Mille, J.A. Robledo, et al., Adv. Healthc. Mater. 9 (2020) 2000156.

doi: 10.1002/adhm.202000156

X. Tan, Y. Wang, W. Du, T. Mu, ChemSusChem 13 (2020) 321–327.

doi: 10.1002/cssc.201902979

K. De France, Z. Zeng, T. Wu, G. Nyström, Adv. Mater. 33 (2021) 2000657.

doi: 10.1002/adma.202000657

Y. Luo, Y. Miao, H. Wang, et al., Nano Res. 16 (2023) 7600–7608.

doi: 10.1007/s12274-023-5382-y

W. Fan, C. Zhang, Y. Liu, et al., Nano Res. 16 (2023) 1–9.

doi: 10.1007/s12274-022-5053-4

H. Ye, J. Jiang, Y. Yang, et al., Adv. Compos. Hybrid Mater. 6 (2023) 81.

doi: 10.1007/s42114-023-00664-x

R. Ilyas, M. Zuhri, M.N.F. Norrrahim, et al., Polymers 14 (2022) 182.

doi: 10.3390/polym14010182

H. Ye, Y. Wang, Q. Yu, et al., Chemosphere 287 (2022) 132436.

doi: 10.1016/j.chemosphere.2021.132436

C. Chen, Y. Zhang, Y. Li, et al., Energy Environ. Sci. 10 (2017) 538–545.

doi: 10.1039/C6EE03716J

W. Kong, C. Wang, C. Jia, et al., Adv. Mater. 30 (2018) 1801934.

doi: 10.1002/adma.201801934

P. Zheng, N. Chen, S. Mahfuzul Islam, et al., ACS Sustain. Chem. Eng. 7 (2018) 3909–3916.

H. Sun, Z. Ren, T. Ji, H. Bi, M. Xu, J. Mater. Res. Technol. 14 (2021) 3043–3050.

doi: 10.1016/j.jmrt.2021.08.153

C. Chen, Y. Wang, Q. Wu, et al., Chem. Eng. J. 400 (2020) 125876.

doi: 10.1016/j.cej.2020.125876

X. Ma, S. Zhao, Z. Tian, et al., Chem. Eng. J. 446 (2022) 136851.

doi: 10.1016/j.cej.2022.136851

H. Ye, G. Zheng, S. Zuo, et al., Appl. Surf. Sci. 615 (2023) 156313.

doi: 10.1016/j.apsusc.2022.156313

Z. Wang, Y. Yu, K. Roy, C. Gao, L. Huang, MDPI 20 (2023) 1871.

E. Zini, M. Scandola, Polym. Compos. 32 (2011) 1905–1915.

doi: 10.1002/pc.21224

G.S. Mann, L.P. Singh, P. Kumar, S. Singh, Compos. Mater. 33 (2020) 1145–1171.

doi: 10.1177/0892705718816354

M. Zhang, G.M. Biesold, W. Choi, et al., Mater. Today 53 (2022) 134–161.

doi: 10.1016/j.mattod.2022.01.022

X. Bi, M. Li, G. Zhou, et al., Nano Res. 12 (2023) 1–14.

R. Ilyas, M. Zuhri, H. Aisyah, et al., Polymers 14 (2022) 202.

doi: 10.3390/polym14010202

S. Amiandamhen, M. Meincken, L. Tyhoda, Fibers Polym. 21 (2020) 677–689.

doi: 10.1007/s12221-020-9362-5

M. Asrofi, E. Syafri, S. Sapuan, R. Ilyas, Key Eng. Mater. 849 (2020) 96–101.

doi: 10.4028/www.scientific.net/kem.849.96

W. Sun, M. Tajvidi, C.G. Hunt, et al., J. Clean. Prod. 353 (2022) 131659.

doi: 10.1016/j.jclepro.2022.131659

T.D. Tavares, J.C. Antunes, F. Ferreira, H.P. Felgueiras, Biomolecules 10 (2020) 148.

doi: 10.3390/biom10010148

K. Rafiee, H. Schritt, D. Pleissner, G. Kaur, S.K. Brar, Curr. Opin. Green Sustain. Chem. 30 (2021) 100482.

doi: 10.1016/j.cogsc.2021.100482

M.J. John, R.D. Anandjiwala, Polym. Compos. 29 (2008) 187–207.

doi: 10.1002/pc.20461

M. Mohammed, R. Rahman, A.M. Mohammed, et al., Polym. Test. 115 (2022) 107707.

doi: 10.1016/j.polymertesting.2022.107707

Y. Liang, G. Zheng, C. Xia, et al., J. Clean. Prod. 351 (2022) 131531.

doi: 10.1016/j.jclepro.2022.131531

S. Kalia, K. Thakur, A. Celli, M.A. Kiechel, C.L. Schauer, J. Environ. Chem. Eng. 1 (2013) 97–112.

doi: 10.1016/j.jece.2013.04.009

J. Manivannan, S. Rajesh, K. Mayandi, et al., J. Nat. Fibers 19 (2022) 4007–4023.

doi: 10.1080/15440478.2020.1848743

S. Bousshine, M. Ouakarrouch, A. Bybi, et al., Appl. Acoust. 187 (2022) 108520.

doi: 10.1016/j.apacoust.2021.108520

H.S. Shekar, M. Ramachandra, Mater. Today Proc. 5 (2018) 2518–2526.

doi: 10.1016/j.matpr.2017.11.034

Z. Zhang, S. Cai, Y. Li, et al., Compos. Sci. Technol. 194 (2020) 108151.

doi: 10.1016/j.compscitech.2020.108151

Y. Leow, V. Sequerah, Y.C. Tan, et al., Compos. B: Eng. 241 (2022) 110031.

doi: 10.1016/j.compositesb.2022.110031

S. Alsubari, M. Zuhri, S. Sapuan, et al., Polymers 13 (2021) 423.

doi: 10.3390/polym13030423

L. Zhao, S. Pan, N. Holzmann, P. Schwerdtfeger, G. Frenking, Chem. Rev. 119 (2019) 8781–8845.

doi: 10.1021/acs.chemrev.8b00722

D. Zhao, M. Feng, L. Zhang, et al., Carbohydr. Polym. 256 (2021) 117580.

doi: 10.1016/j.carbpol.2020.117580

S. Godara, Mater. Today Proc. 18 (2019) 3428–3434.

doi: 10.1016/j.matpr.2019.07.270

Y.L. Loow, T.Y. Wu, J. Md. Jahim, A.W. Mohammad, W.H. Teoh, Cellulose 23 (2016) 1491–1520.

doi: 10.1007/s10570-016-0936-8

C. Huang, Y. Zhan, J. Wang, et al., Green Chem. 24 (2022) 3736–3749.

doi: 10.1039/d2gc00301e

G. Zheng, H. Ye, Y. Liang, et al., Constr. Build. Mater. 367 (2023) 130350.

doi: 10.1016/j.conbuildmat.2023.130350

R. Vijay, D.L. Singaravelu, A. Vinod, et al., Int. J. Biol. Macromol. 125 (2019) 99–108.

doi: 10.1016/j.ijbiomac.2018.12.056

M. Beg, K. Pickering, Mater. Manuf. Proc. 21 (2006) 303–307.

doi: 10.1080/10426910500464750

M.N. Izani, M. Paridah, U. Anwar, M.M. Nor, P. H’ng, Compos. B: Eng. 45 (2013) 1251–1257.

doi: 10.1016/j.compositesb.2012.07.027

W. Lv, Z. Xia, Y. Song, et al., Ind. Crops. Prod. 171 (2021) 113934.

doi: 10.1016/j.indcrop.2021.113934

J. He, C. Huang, C. Lai, et al., Ind. Crops. Prod. 146 (2020) 112205.

doi: 10.1016/j.indcrop.2020.112205

E.S. Ferreira, E.D. Cranston, C.A. Rezende, ACS Sustain. Chem. Eng. 8 (2020) 8267–8278.

doi: 10.1021/acssuschemeng.0c01480

S. Ma, Y. Yan, C. He, et al., Ind. Crops. Prod. 180 (2022) 114712.

doi: 10.1016/j.indcrop.2022.114712

R. Yang, Q. Cao, Y. Liang, et al., Chem. Eng. J. 401 (2020) 126150.

doi: 10.1016/j.cej.2020.126150

Z. Li, C. Chen, H. Xie, et al., Nat. Sustain. 5 (2022) 235–244.

J. Song, C. Chen, S. Zhu, et al., Nature 554 (2018) 224–228.

doi: 10.1038/nature25476

X. Lv, J. Han, M. Liu, et al., Chem. Eng. J. 452 (2022) 139439.

M.H. Mohamed, I.A. Udoetok, L.D. Wilson, Compos. Sci. Technol. 4 (2020) 15.

T.V. Thanh, L.T. Hao, H.Y. Cho, et al., ACS Sustain. Chem. Eng. 10 (2022) 8411–8422.

doi: 10.1021/acssuschemeng.2c01395

C. Calvino, N. Macke, R. Kato, S.J. Rowan, Prog. Polym. Sci. 103 (2020) 101221.

doi: 10.1016/j.progpolymsci.2020.101221

C. Gilbert, T.C. Tang, W. Ott, et al., Nat. Mater. 20 (2021) 691–700.

doi: 10.1038/s41563-020-00857-5

Y. Wan, P. Xiong, J. Liu, et al., ACS Nano 15 (2021) 8439–8449.

doi: 10.1021/acsnano.0c10666

C. Li, H. Lei, Z. Wu, et al., ACS Appl. Mater. Interfaces 14 (2022) 23859–23867.

doi: 10.1021/acsami.2c02859

J. Zhang, C. Long, X. Zhang, et al., Chem. Eng. J. 450 (2022) 138387.

doi: 10.1016/j.cej.2022.138387

M. Bai, J. Cao, J. Li, C. Li, J. Clean. Prod. 321 (2021) 129001.

doi: 10.1016/j.jclepro.2021.129001

P.P. Das, V. Chaudhary, S. Mishra, Composite materials: properties, fabrication and applications, in: B. Sharma, P. Jain (Eds.), Graphene Based Biopolymer Nanocomposites, Springer, Singapore, 2021, pp. 1–24.

A. Vedrtnam, S. Kumar, S. Chaturvedi, Compos. B: Eng. 176 (2019) 107282.

doi: 10.1016/j.compositesb.2019.107282

F. Erchiqui, H. Kaddami, G. Dituba-Ngoma, F. Slaoui-Hasnaoui, Int. J. Heat Mass Transf. 158 (2020) 119996.

doi: 10.1016/j.ijheatmasstransfer.2020.119996

D. Basalp, F. Tihminlioglu, S.C. Sofuoglu, F. Inal, A. Sofuoglu, Waste Biomass Valori. 11 (2020) 5419–5430.

doi: 10.1007/s12649-020-00986-7

A.H. Elsheikh, H. Panchal, S. Shanmugan, et al., Clean Technol. Environ. Policy 8 (2022) 100450.

doi: 10.1016/j.clet.2022.100450

Y. Zhou, P. Stanchev, E. Katsou, S. Awad, M. Fan, Waste Manage. 99 (2019) 42–48.

doi: 10.1117/12.2523386

S. Han, X. Zhou, H. Xie, et al., Chemosphere 305 (2022) 135486.

doi: 10.1016/j.chemosphere.2022.135486

G.J. Jiao, J. Ma, Y. Li, et al., J. Hazard. Mater. 421 (2022) 126722.

doi: 10.1016/j.jhazmat.2021.126722

Q. Wang, X. Pan, C. Lin, et al., Chem. Eng. J. 370 (2019) 1039–1047.

doi: 10.3390/f10111039

A. Moreno, M.H. Sipponen, Mater. Horizons 7 (2020) 2237–2257.

doi: 10.1039/d0mh00798f

W. Huang, S. Ling, C. Li, F.G. Omenetto, D.L. Kaplan, Chem. Soc. Rev. 47 (2018) 6486–6504.

doi: 10.1039/C8CS00187A

J. Deng, M. Li, Y. Wang, Green Chem. 18 (2016) 4824–4854.

doi: 10.1039/C6GC01172A

Z. Li, C. Chen, R. Mi, et al., Adv. Mater. 32 (2020) 1906308.

doi: 10.1002/adma.201906308

S. Xiao, C. Chen, Q. Xia, et al., Science 374 (2021) 465–471.

doi: 10.1126/science.abg9556

A.Le Duigou, D. Correa, M. Ueda, R. Matsuzaki, M. Castro, Mater. Des. 194 (2020) 108911.

doi: 10.1016/j.matdes.2020.108911

U. Ray, S. Zhu, Z. Pang, T. Li, Adv. Mater. 33 (2021) 2002504.

doi: 10.1002/adma.202002504

C. Chen, Z. Li, R. Mi, et al., ACS Nano 14 (2020) 5194–5202.

doi: 10.1021/acsnano.9b08747

N. Van de Werken, H. Tekinalp, P. Khanbolouki, et al., Adv. Mater. 31 (2020) 100962.

J. Garemark, X. Yang, X. Sheng, et al., ACS Nano 14 (2020) 7111–7120.

doi: 10.1021/acsnano.0c01888

X. Han, W. Wu, Z. Tian, et al., Compos. Commun. 33 (2022) 101199.

doi: 10.1016/j.coco.2022.101199

Q. Xia, C. Chen, Y. Yao, et al., Nat. Sustain. 4 (2021) 627–635.

doi: 10.1038/s41893-021-00702-w

S. Gao, Z. Cheng, X. Zhou, et al., Chem. Eng. J. 394 (2020) 124896.

doi: 10.1016/j.cej.2020.124896

Y. Wang, Z. Li, D. Yang, et al., Nat. Sustain. 583 (2021) 80–88.

Y. Gong, L. Xie, C. Chen, et al., Prog. Mater. Sci. 132 (2022) 101048.

E. Guzman, R.G. Rubio, F. Ortega, Adv. Colloid Interface Sci. 282 (2020) 102197.

doi: 10.1016/j.cis.2020.102197

M. Lian, Y. Huang, Y. Liu, et al., Adv. Compos. Hybrid Mater. 5 (2022) 1612–1657.

doi: 10.1007/s42114-022-00475-6

Z. Bi, Q. Kong, Y. Cao, et al., J. Mater. Chem. A 7 (2019) 16028–16045.

doi: 10.1039/c9ta04436a

R. Brandes, D. Belosinschi, F. Brouillette, B. Chabot, J. Environ. Chem. Eng. 7 (2019) 103477.

doi: 10.1016/j.jece.2019.103477

B. Thomas, M.C. Raj, J. Joy, et al., Chem. Rev. 118 (2018) 11575–11625.

doi: 10.1021/acs.chemrev.7b00627

P. Phanthong, P. Reubroycharoen, X. Hao, et al., Energy Convers. Manag. 1 (2018) 32–43.

C. Chen, L. Berglund, I. Burgert, L. Hu, Adv. Mater. 33 (2021) 2006207.

doi: 10.1002/adma.202006207

E.J. Foster, R.J. Moon, U.P. Agarwal, et al., Chem. Soc. Rev. 47 (2018) 2609–2679.

doi: 10.1039/c6cs00895j

D.Y. Liu, G. Sui, D. Bhattacharyya, Compos. Sci. Technol. 99 (2014) 31–36.

doi: 10.1201/b16752-6

C. Zheng, K. Lu, Y. Lu, et al., Carbohydr. Polym. 250 (2020) 116905.

doi: 10.1016/j.carbpol.2020.116905

X. Wang, Q. Xia, S. Jing, et al., Small 17 (2021) 2008011.

doi: 10.1002/smll.202008011

M.E. Lamm, K. Li, J. Qian, et al., Adv. Mater. 33 (2021) 2005538.

doi: 10.1002/adma.202005538

A. Hänninen, E. Sarlin, I. Lyyra, et al., Carbohydr. Polym. 202 (2018) 418–424.

doi: 10.1016/j.carbpol.2018.09.001

A. Dorieh, M.F. Pour, S.G. Movahed, et al., Prog. Org. Coat. 165 (2022) 106768.

doi: 10.1016/j.porgcoat.2022.106768

S. Gerassimidou, O.V. Martin, S.P. Chapman, J.N. Hahladakis, E. Iacovidou, J. Clean. Prod. 286 (2021) 125378.

doi: 10.1016/j.jclepro.2020.125378

A.T. Adeleye, C.K. Odoh, O.C. Enudi, et al., Proc. Biochem. 96 (2020) 174–193.

doi: 10.1016/j.procbio.2020.05.032

Y. Chen, J. Fu, B. Dang, et al., ACS Nano 14 (2020) 2036–2043.

doi: 10.1021/acsnano.9b08647

Y. Yang, Y. Ren, S. Ge, et al., Appl. Surf. Sci. 606 (2022) 154595.

doi: 10.1016/j.apsusc.2022.154595

Y. Liu, Y. Ke, Q. Shang, et al., Chem. Eng. J. 451 (2023) 138934.

doi: 10.1016/j.cej.2022.138934

A. Hai, G. Bharath, K.R. Babu, et al., Process Saf. Environ. Prot. 129 (2019) 103–111.

doi: 10.1016/j.psep.2019.06.024

N. Tian, S. Wu, G. Han, et al., J. Hazard. Mater. 424 (2022) 127393.

doi: 10.1016/j.jhazmat.2021.127393

T. Meng, B. Jiang, Z. Li, et al., Nano Energy 87 (2021) 106146.

doi: 10.1016/j.nanoen.2021.106146

C. Liang, H. Qiu, P. Song, et al., Sci. Bull. 65 (2020) 616–622.

doi: 10.1016/j.scib.2020.02.009

K. Petersen, P.V. Nielsen, G. Bertelsen, et al., Trends Food Sci. Technol. 10 (1999) 52–68.

doi: 10.1016/S0924-2244(99)00019-9

A. Biswas, I.S. Bayer, A.S. Biris, et al., Adv. Colloid Interface Sci. 170 (2012) 2–27.

doi: 10.1016/j.cis.2011.11.001

X. Li, M. Younas, M. Rezakazemi, Q.V. Ly, J. Li, Chin. Chem. Lett. 33 (2022) 3594–3602.

doi: 10.1016/j.cclet.2021.10.044

J. Ma, J. He, X. Kong, et al., Chin. Chem. Lett. 34 (2022) 107407.

N. Mittal, F. Ansari, K. Gowda, et al., ACS Nano 12 (2018) 6378–6388.

doi: 10.1021/acsnano.8b01084

Q.F. Guan, Z.M. Han, H.B. Yang, Z.C. Ling, S.H. Yu, Natl. Sci. Rev. 8 (2021) nwaa230.

doi: 10.1093/nsr/nwaa230

L. Liu, H. Li, A. Lazzaretto, et al., Renew. Sust. Energ. Rev. 69 (2017) 912–932.

doi: 10.1016/j.rser.2016.11.140

N.A. Nguyen, C.C. Bowland, A.K. Naskar, Appl. Mater. Today 12 (2018) 138–152.

doi: 10.1016/j.apmt.2018.03.009

A. Rath, B. Grisin, T.D. Pallicity, et al., Compos. Sci. Technol. 235 (2023) 109952.

doi: 10.1016/j.compscitech.2023.109952

Z. Zhu, W. Wang, Z. Liu, et al., Ind. Crops. Prod. 185 (2022) 115106.

doi: 10.1016/j.indcrop.2022.115106

C.B. Godiya, L.A.M. Ruotolo, W. Cai, J. Mater. Chem. A 8 (2020) 21585–21612.

doi: 10.1039/d0ta07028a

X. Huang, Y. Liu, X. Wang, et al., Int. J. Env. Pub. he. 19 (2022) 10897.

doi: 10.3390/ijerph191710897

S. Liu, X. Tian, X. Zhang, et al., Chin. Chem. Lett. 33 (2022) 2205–2211.

doi: 10.1016/j.cclet.2021.09.063

P. Mei, R. Wu, S. Shi, et al., Chem. Eng. J. 420 (2021) 130382.

doi: 10.1016/j.cej.2021.130382

Y. Hu, M. Shi, L. Liu, J. Yu, Y. Fan, Int. J. Biol. Macromol. 174 (2021) 162–174.

doi: 10.1016/j.ijbiomac.2021.01.159

G. Chen, T. Li, C. Chen, et al., ACS Nano 15 (2021) 11244–11252.

doi: 10.1021/acsnano.0c10117

W. Chao, S. Wang, Y. Li, et al., Chem. Eng. J. 400 (2020) 125865.

doi: 10.1016/j.cej.2020.125865

Y. Zhang, W. Cui, W. An, et al., Appl. Catal. B 221 (2018) 36–46.

doi: 10.1016/j.apcatb.2017.08.076

L. Huang, X. Huang, J. Yan, et al., J. Hazard. Mater. 442 (2023) 130024.

doi: 10.1016/j.jhazmat.2022.130024

M. Ghazaie, M. Ghiaci, S. Soleimanian Zad, S. Behzadi Teshnizi, J. Hazard. Mater. 371 (2019) 224–232.

doi: 10.1016/j.jhazmat.2019.03.003

H.D. Thi, S.Y. Kim, S.Y. Jung, et al., SSRN 31 (2023) 4394136.

H. Gu, C. Gao, X. Zhou, et al., Adv. Compos. Hybrid Mater. 4 (2021) 459–468.

doi: 10.1007/s42114-021-00289-y

H. Zhao, X.K. Ouyang, L.Y. Yang, J. Mol. Liq. 324 (2021) 115122.

doi: 10.1016/j.molliq.2020.115122

C.C. Wang, X. Wang, W. Liu, Chem. Eng. J. 391 (2020) 123601.

doi: 10.1016/j.cej.2019.123601

T. Meng, Z. Li, Z. Wan, et al., Chem. Eng. J. 452 (2023) 139193.

doi: 10.1016/j.cej.2022.139193

X. Niu, X. Li, Z. Lyu, et al., ChemComm 56 (2020) 11338–11353.

doi: 10.1039/d0cc04890a

W. Zhu, R. Michalsky, O.n. Metin, et al., J. Am. Chem. Soc. 135 (2013) 16833–16836.

doi: 10.1021/ja409445p

Z. Su, Y. Yang, Q. Huang, et al., Prog. Mater. Sci. 125 (2022) 100917.

doi: 10.1016/j.pmatsci.2021.100917

Z.U. Arif, M.Y. Khalid, M.F. Sheikh, A. Zolfagharian, M. Bodaghi, J. Environ. Chem. Eng. 10 (2022) 108159.

doi: 10.1016/j.jece.2022.108159

T. Wu, Y. Song, Z. Shi, et al., Nano Energy 80 (2021) 105541.

doi: 10.1016/j.nanoen.2020.105541

S.Y. Lu, M. Jin, Y. Zhang, et al., Adv. Energy Mater. 8 (2018) 1702545.

doi: 10.1002/aenm.201702545

Q. Lin, S. Liu, X. Wang, Y. Huang, W. Yu, Appl. Surf. Sci. 575 (2022) 151700.

doi: 10.1016/j.apsusc.2021.151700

W. Gan, C. Chen, M. Giroux, et al., Chem. Mater. 32 (2020) 5280–5289.

doi: 10.1021/acs.chemmater.0c01507

L. Gu, J. Han, M. Chen, et al., Energy Stor. Mater. 52 (2022) 547–561.

X. Han, W. Zhou, M. Chen, et al., J. Energy Chem. 67 (2022) 727–735.

doi: 10.1016/j.jechem.2021.11.021

Y. Wang, S. Hou, T. Li, et al., ACS Appl. Mater. Interfaces 12 (2020) 41896–41904.

doi: 10.1021/acsami.0c12868

J. Huang, D. Li, M. Zhao, et al., Chem. Eng. J. 373 (2019) 1357–1366.

doi: 10.1016/j.cej.2019.05.136

T. Lu, Y. Liu, X. Xu, et al., Sep. Purif. Technol. 256 (2021) 117771.

doi: 10.1016/j.seppur.2020.117771

X. Sheng, X. Xu, Y. Wu, et al., Bull. Chem. Soc. Jpn. 94 (2021) 1645–1650.

doi: 10.1246/bcsj.20210029

C.C. Wang, J.R. Li, X.L. Lv, Y.Q. Zhang, G. Guo, Energy Environ. Sci. 7 (2014) 2831–2867.

doi: 10.1039/C4EE01299B

Xinguo Mao , Shuo Zhang , Qiang Shi , Hua Cheng , Leyong Wang . Macrocyclic host molecules: Rising as a promising supramolecular material. Chinese Chemical Letters, 2025, 36(6): 110950-. doi: 10.1016/j.cclet.2025.110950

Ziyang Yin , Lingbin Xie , Weinan Yin , Ting Zhi , Kang Chen , Junan Pan , Yingbo Zhang , Jingwen Li , Longlu Wang . Advanced development of grain boundaries in TMDs from fundamentals to hydrogen evolution application. Chinese Chemical Letters, 2024, 35(5): 108628-. doi: 10.1016/j.cclet.2023.108628

Pingfan Zhang , Shihuan Hong , Ning Song , Zhonghui Han , Fei Ge , Gang Dai , Hongjun Dong , Chunmei Li . Alloy as advanced catalysts for electrocatalysis: From materials design to applications. Chinese Chemical Letters, 2024, 35(6): 109073-. doi: 10.1016/j.cclet.2023.109073