Ultrasmall green-emitting carbon nanodots with 80% photoluminescence quantum yield for lysosome imaging

-

* Corresponding author.

E-mail address: wufg@seu.edu.cn (F.-G. Wu).

Citation:

Xiaokai Chen, Xiaodong Zhang, Fu-Gen Wu. Ultrasmall green-emitting carbon nanodots with 80% photoluminescence quantum yield for lysosome imaging[J]. Chinese Chemical Letters,

;2021, 32(10): 3048-3052.

doi:

10.1016/j.cclet.2021.03.061

Over the past 20 years, significant progress has been made on the development of macromolecular drugs, which has revolutionized the therapy of various diseases [1]. Macromolecular drugs mainly with nucleic acids- and proteins-based structures possess unique advantages over small molecular drugs such as extremely high specificity and affinity, and sophisticated biofunctions [2], which provides new hope for the treatment of currently intractable diseases (i.e., cancer, atherosclerosis, and rheumatoid arthritis) [3,4]. However, the structural complexity of this type of drugs raises several common druggable challenges. For example, the macromolecules without chemical modifications are unstable in systemic circulation and prone to biological degradation by proteolysis (for proteins) and nucleases (for nucleic acids). In addition, macromolecules cannot freely penetrate the biological barriers and cell membrane for action because of their big size. Therefore, the development of suitable drug delivery systems is highly desired for macromolecular drugs [5-8].

Currently, extensive research attention has been paid on the design of polymer- and lipid-based nanostructures for delivery of macromolecular drugs, such as cationic polymers for siRNA and lipid nanoparticles for mRNA vaccines [9]. While great success has been made, these delivery systems have several intrinsic limitations, including tedious materials synthesis, complex preparation procedure, and potential toxicity of the carriers. In addition, the complex and large size of the drugs impose difficulty for effective encapsulation, and the loading is usually achieved via electrostatic interaction, which however brings the risk of pre-mature leakage during in vivo circulation, compromising the final efficacy. Therefore, the development of simple yet robust carriers to deliver macromolecules still remains a challenge.

In this regard, inorganic nanoplatforms formed by biomineralization may offer an alternative choice, as the basic process of biomineralization is the interaction between inorganic ions (mainly metals) with biomacromolecules to form hard biomaterials [10]. Compared with organic carriers, biomineralization-based nanoparticles are advantageous for simple preparation, cost effectiveness, good physiological stability, excellent biocompatibility, and degradability [11]. Metal ions can interact with macromolecules via different binding force [12], such as electrostatic attraction, coordination, and hydrogen bond (via metal hydration), thus enabling better encapsulation efficiency and stability. For example, calcium minerals, including calcium carbonate and calcium phosphate, are the most extensively studied biomineralized carriers to deliver a broad range of drugs including nucleic acids and proteins [13,14]. Of note, transition metals are the better candidates than calcium for macromolecules binding because of their stronger coordination affinity with macromolecules [12]. However, the attempt of using transition metal as biomineralized carrier to load macromolecular drugs has been rarely explored.

Herein, we report the rational screen of biocompatible transition metal ions to biomineralize with carbonate for macromolecular drugs loading, in which Cu2+ turns out to be the best choice with extra high loading capacity, stability, and pH-responsive drug release profile. As a proof-of-concept, copper carbonate nanoparticles were prepared to co-load glucose oxidase (GOx) and a HIF-α DNAzyme (DZ). Such nanomedicine could achieve multimodal tumor therapy via GOx-based starvation therapy, copper-based chemodynamic therapy (CDT), as well as HIF-α silencing for anti-tumor sensitization.

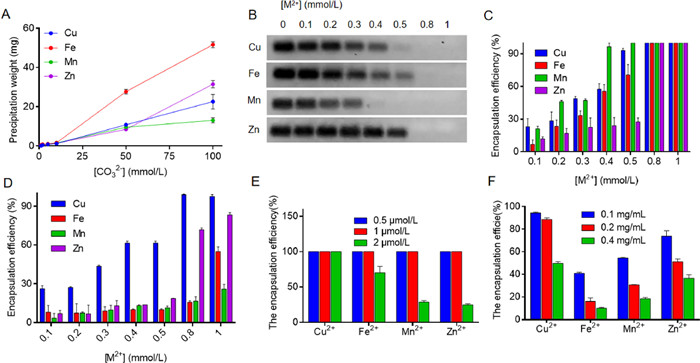

Various types of metal ions have been known to interact with carbonate for biomineralization [15]. Considering potential biomedical applications, several biological related and low toxic metal ions, including Cu2+, Fe2+, Mn2+ and Zn2+, were tested in this work. To conveniently evaluate their mineralization, metal ions were incubated with CO32− solutions (Fig. S1 in Supporting information), and the resulting precipitants were weighted (Fig. 1A). With fixing metal ion concentration at 100 mmol/L, the weight of precipitates gradually increased at higher carbonate anion concentrations for all types of metals. Note that, the precipitations were all formed in 1 min upon reaction, indicating their rapid mineralization. Among them, Fe2+ produced the most abundant precipitants, and its color changed rapidly from brownish yellow to blackish green, likely due to the oxidation of the unstable Fe2+ to Fe3+ in test tube. As the main purpose, we screened all the biomineralized precipitation for macromolecules loading, in which a 20-nt random DNA and bovine serum albumin (BSA) was employed for proof-of-concept demonstration. With fixed BSA (0.2 mg/mL)/DNA (1 µmol/L) and CO32− (1 mmol/L) concentrations, various metal ions were titrated. The DNA was labeled with a FAM fluorophore, and the encapsulation of DNA into the biomineralized precipitation was calculated by quantifying the unloaded DNA in solution using PAGE gel electrophoresis (Fig. 1B). The loading efficiency of various metal ions was then analyzed (Fig. 1C), in which all of them could completely load the DNA at metal concentration at 0.8 mmol/L or higher, ascribing to strong and multiple binding sites between the transition metal ions and DNA. It should be also noted that Mn2+ and Cu2+ seemed to have better efficiency at low metal concentrations. Similarly, the unloaded BSA was measured by Bradford assay, and the result was quantified (Fig. 1D). In this case, Cu2+ showed much better efficiency than other metals to load the protein. Therefore, biomineralization between transition metal ions and CO32− might be a promising method to load macromolecules of both nucleic acids and proteins.

To test the real applications, we further explored such strategy to load therapeutic macromolecules, in which a DNAzyme (DZ) and glucose oxidase (GOx) were employed as model therapeutic nucleic acid and protein, respectively. DNAzyme is a type of DNA-based catalyst, which could catalyze a wide range of chemical reactions [16]. Here we used an RNA-cleavage DNAzyme that can cleave the mRNA of interest for gene silencing application, and the HIF-1α mRNA was designed as the target since HIF-1α plays critical roles for tumor development, progress and metastasis [17]. GOx, on the other hand, was initially used to treat upper respiratory tract infections (NCT01883427), while recent studies have found its potential for tumor starvation therapy via catalytic glucose consumption [18]. Three concentrations of both DZ and GOx were tested (Figs. 1E and F), and it was found that Cu2+ had the best loading capacity for both of them. Moreover, such biomineralization could realize DZ and GOx co-loading, and again, the Cu2+ was the most efficient one (Fig. S2 in Supporting information). Moreover, we further tested the extensively studied Ca2+ for side-by-side comparison. Cu2+ was much more efficient to biomineralize with CO32− based on the precipitant formation. Importantly, Cu2+ showed significantly better activity to load both GOx and DZ, owing to more precipitant formation and stronger binding affinity (Fig. S3 in Supporting information).

The above experiments have indicated that the copper carbonate was the best candidate for macromolecules loading. We next explored such carrier for biomedical applications by preparing copper carbonate nanoparticles. The nanoparticles were prepared by just mixing CuCl2 with GOx and DZ, followed by add Na2CO3 under ultrasonic condition. After 30 min incubation, the GOx/DZ@Cu NPs were formed showing typical Tyndall phenomenon (Fig. S4 in Supporting information). The nanoparticles had hydrodynamic size and ζ potential of ~130 nm and −12 mV, respectively (Fig. 2A and Fig. S5 in Supporting information). Interestingly, without DZ/GOx loading, such biomineralized material aggregated rapidly, suggesting a stabilization effect of the macromolecules via their strong interaction with the nanoparticles. From TEM, the nanoparticles showed spherical morphology with multi-dispersed size ranging from 100 nm to 200 nm (Fig. 2B). The elemental mapping was further investigated, in which the S and P elements were observed all around and outside the nanoparticles (Fig. 2C), assigning to the GOx and DZ loading. The encapsulation efficiency of GOx and DZ were further measured to be 69% and 77%, respectively, giving drug loading capacity to be 57% (for GOx) and 4% (for DZ). Therefore, overall loading capacity reached up to 61%, which was significantly higher than most organic materials, highlighting the advantage of such system for biomolecules loading.

Having confirmed the structure, we then explored the properties of the nanoparticles. First, the drug release profile was studied, in which the concentration of GOx and DZ were measured by gel electrophoresis and Bradford assay as described above. Notably, both GOx and DZ showed quite similar release profiles, in which the drugs were stably loaded under physiological mimic condition of pH 7.4, while a burst release within 1 h was observed at acidic pH of 5.5 (Figs. 2D and E). Such pH-responsive property is highly appreciable for drug delivery, since it can prevent pre-mature drug release during in vivo circulation, while rapidly release drugs upon reaching the target cells. Actually, the carbonate-based metal nanoparticles share the similar pH-responsive property, in which the calcium carbonate is the most extensively studied one [13]. The common mechanism is the dissolution of CO32− at acidic condition, accompanied by the release of the drugs. The nanoparticle dissolution was further probed by centrifugation, in which almost no precipitation was observed after acidic pre-treatment (Fig. S6 in Supporting information).

Different from small molecular drugs, one key consideration of macromolecules delivery is their retained biofunctions after being delivered to the target site. GOx could catalyze the oxidization of glucose into gluconic acid and hydrogen peroxide (H2O2) with consumption of molecular oxygen. Therefore, the activity of GOx can be easily monitored by measuring O2 and pH decrease. At pH 7.4, the GOx/DZ@Cu NPs did not show any catalytic activity, due to the passivation of GOx upon loading into nanoparticles (Figs. S7 and S8 in Supporting information). Notably, such deactivation is meaningful to decrease the side-effect of GOx during circulation, i.e., the catalytic consumption of glucose to cause glycopenia [19]. With acidic buffer pre-treatment, an obvious catalytic activity was observed for GOx/DZ@Cu NPs, attributable to the collapse of the nanoparticles to release GOx. Notably, its activity could recover to the level compatible to free GOx (Fig. S9 in Supporting information), indicating that the biomineralized encapsulation has little effect on biofunction of the enzyme. Meanwhile, the catalytic activity of the DZ to cleavage target mRNA was tested. Free DZ could effectively cleave the substrate in presence of the intracellular abundant Mg2+ to produce the cleaved band on gel image (Fig. S10 in Supporting information). For GOx/DZ@Cu NPs, the cleavage was only observed at pH 5.5 buffer, consistent with the above results, which was also ascribed to the pH-dependent release of DZ.

Compared to the widely studied calcium carbonate, one extra merit of copper carbonate nanoparticles is the pH-responsive release of copper ion to induce tumor chemodynamic therapy (CDT) via Fenton-like reaction. To demonstrate this, the GOx/DZ@Cu NPs was pre-treated with acidic buffer to release Cu2+, followed by adding H2O2 and GSH. GSH could reduce Cu2+ into Cu+, which then decomposes H2O2 into toxic •OH. The •OH generation was probed by methylene blue (MB), which could be rapidly degraded by •OH accompanied by the decrease of UV–vis absorbance at 664 nm. As expected, the released Cu2+ from GOx/DZ@Cu NPs after acidic pre-treatment could induce a strong CDT effect, while such Fenton effect was much weaker under physiological condition (pH 7.4) owing to pH responsive release of Cu2+ (Fig. S11 in Supporting information). Of note, GOx/DZ@Cu NPs with GOx loading could catalyze the H2O2 generation during glucose consumption, which further boosts the CDT efficacy. To confirm this, free glucose was added instead of H2O2, and as expected, a concentration dependent CDT effect was observed (Fig. S12 in Supporting information). Therefore, the co-loaded GOx could not only exert tumor starvation therapy via glucose consumption, but also promote the CDT through catalytic generation of H2O2, achieving a synergistic effect.

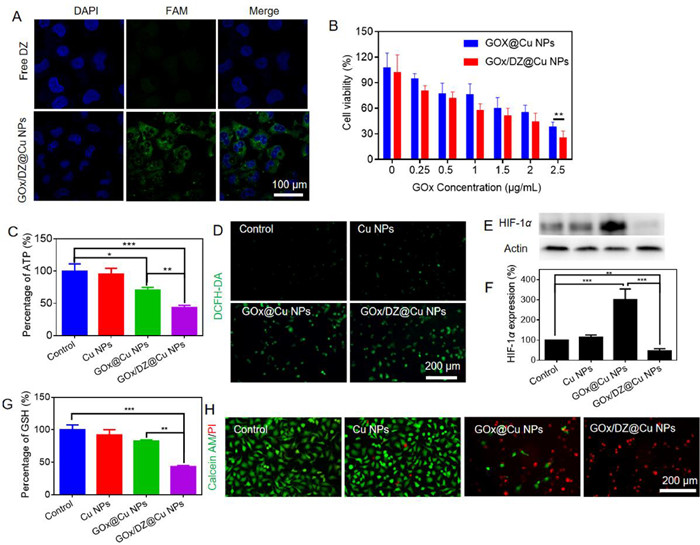

Next, the intracellular performances of the nanoparticles were explored by using M231 breast cancer as example. To explore the cell transport, the loading DZ was labeled with FAM fluorophore, and the cell nuclei were stained blue by Hoechst 33342. As a common limitation, the macromolecules usually have low cell penetration efficiency, and thus transfection reagents are required. The negatively charged DNA is repelled by cell membrane, resulting in extremely weak fluorescence inside cells for free DZ (Fig. 3A). For GOx/DZ@Cu NPs, by contrast, the cells emitted bright fluorescence, suggesting nanoparticles-mediated DZ delivery. Therefore, the Cu NPs could serve as an effective carrier for intracellular delivery of macromolecules.

The anti-tumor activity was then evaluated by MTT assay [20]. In absence of the payloads, the Cu NPs did not show any cytotoxicity at concentration up to 25 µmol/L (Fig. S13 in Supporting information), which can be explained by the poor CDT effect with limited level of H2O2 inside cells. Therefore, Cu NPs alone was a biocompatible material. With GOx loading (the nanoparticles termed GOx@Cu NPs), a concentration-dependent decrease of cell viability was seen (Fig. 3B), attributable to catalytic starvation therapy. To confirm this, the intracellular ATP level was measured (Fig. 3C). GOx@Cu NPs could significantly reduce the ATP level, verifying the blockage of energy supply. Moreover, the GOx-catalyzed generation of H2O2 would also contribute to the enhanced anti-tumor effect by promoting CDT. To probe this, ROS generation, the biomarker of CDT, was visualized by using 2′, 7′-dichlorofluorescin diacetate (DCFH-DA) indicator with green fluorescence. Compared to the control, Cu NPs barely showed any fluorescence, confirming its weak CDT effect (Fig. 3D). However, a strong fluorescence was noticed for the cells with GOx@Cu NPs treatment, indicating the sensitization of GOx on CDT.

Interestingly, the additional DZ loading could further promote anti-tumor effect (Fig. 3B), resulting in 27.8% lower IC50 value of GOx/DZ@Cu NPs than that of GOx@Cu NPs. The enhanced effect can be ascribed to DZ-mediated HIF-1α suppression, which has been confirmed by Western blot analysis of this protein (Figs. 3E and F), and several mechanisms can explain such results. First, the GOx-mediated starvation therapy exacerbates the tumor hypoxia via oxygen consumption, which in turn stimulates the upregulation of HIF-1α to adapt tumor hypoxia with better survival. Our result also confirmed this effect with significantly upregulation of HIF-1α with GOx@Cu NPs therapy. GOx/DZ@Cu NPs treatment, by contrast, significantly suppressed the expression of HIF-1α, confirming the intracellular activation of the DZ. Meanwhile, the regulation of HIF-1α could also reverse the cell oxidative protection system, as evidenced by the decrease of GSH level, the major anti-oxidant system inside cells, after GOx/DZ@Cu NPs treatment (Fig. 3G) [21]. Therefore, DZ-induced HIF-1α inhibition could block all these negative effects to sensitize both starvation therapy and CDT.

To further confirm the antitumor activity, we next performed the live/dead cell staining assay, in which the live cells and dead cells were stained with Calcein-AM (green fluorescence) and PI (red fluorescence), respectively. Bright green fluorescence was seen inside cells after Cu NPs treatment, confirming the minimal cytotoxicity of the nanoparticles. For GOx/DZ@Cu and GOx@Cu groups, on the contrary, the red fluorescence became intensified with a large number of cells being dead. Among various treatment, GOx/DZ@Cu produced the highest intensity of red fluorescence, consistent with the above results (Fig. 3H).

Finally, the in vivo behavior of GOx/DZ@Cu NPs was explored by using M231 tumor-bearing mice. All experimental procedures were approved by the Ethics Committee for Research in Animal Subjects at Xiangya School of Pharmaceutical Sciences of Central South University. Owing to its high hemocompatibility (Fig. S14 in Supporting information), the nanoparticle was administrated via tail intravenous injection. To study the biodistribution, the DZ was labeled with a Cy5.5 NIR fluorophore for in vivo imaging using the IVIS Lumia XRMS series III system. Free DZ or GOx/DZ@Cu NPs were injected when the tumor volume reached about 100 mm3. At 1 h post injection, free DZ showed high fluorescence throughout the body (Fig. S15A in Supporting information), indicating non-specific distribution, while the fluorescence was strongly weakened at 24 h, due to the rapid degradation and clearance of the nucleic acids. Because of the fluorescence quenching effect, GOx/DZ@Cu NPs initially emitted weak fluorescence at 1 h, but the fluorescence was recovered at 24 h, suggesting a long circulation effect of the nanoparticles. Specifically, we observed a notable signal at tumor site for GOx/DZ@Cu NPs. To verify this, the tumor tissue and major organs were extracted at 24 h post-injection for ex vivo fluorescence imaging and quantification (Fig. S15B in Supporting information). Obviously, GOx/DZ@Cu NPs exhibited higher intensity at tumor site than free DZ, confirming targetability of the nanoparticles to accumulate into tumor via EPR effect. Meanwhile, we also noticed considerable accumulation of NPs in liver and kidneys, which were the main organs to sequester and eliminate NPs from body.

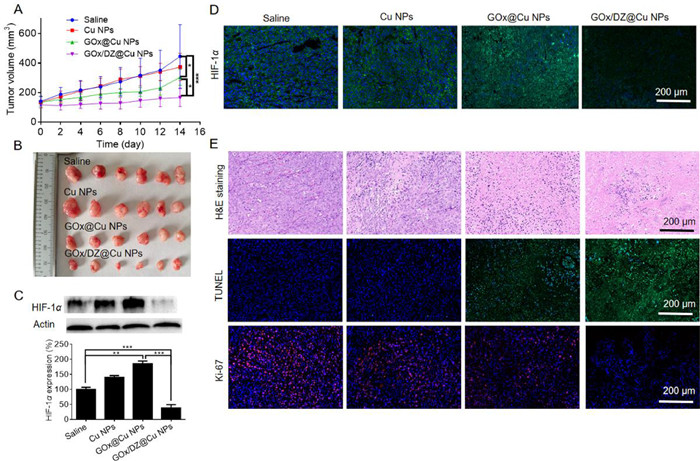

To explore the anti-tumor activity, the tumor-bearing mice were randomly divided into four groups (n = 6), each receiving one of the following treatments: saline (control), Cu NPs, GOx@Cu NPs and GOx/DZ@Cu NPs (with an equivalent GOx dosage of 2 mg/kg), respectively. The anti-tumor effect was dynamically monitored every other day by measuring the tumor volume. Compared to the control, only marginal tumor growth inhibition was observed for Cu NPs (Fig. 4A). With GOx encapsulation, the anti-tumor effect of GOx@Cu NPs was significantly enhanced. Notably, the best efficacy was observed for GOx/DZ@Cu NPs, achieving 83% tumor growth suppression efficiency. For convenient observation, the tumor was collected and weighted after treatments (Fig. 4B and Fig. S16 in Supporting information), and the overall therapeutic efficacy was in order of GOx/DZ@Cu NPs > GOx@Cu NPs > Cu NPs. Therefore, the combination of DZ could sensitize the efficacy of both CDT and starvation therapy via its HIF-1α regulation effect. To confirm the in vivo activation of DZ, the expression of HIF-1α was investigated by both western blot and immunofluorescence assay (Figs. 4C and D). While Cu NPs has little marginal effect, GOx@Cu NPs could significantly promote the expression of HIF-1α owing to the catalytic O2 consumption to exacerbate tumor hypoxia. With DZ co-loading, GOx/DZ@Cu NPs could reverse the adverse effect of GOx to effectively downregulate HIF-1α, which in turn contributed to the enhanced tumor therapy. The anti-tumor activity was further evaluated by pathologically analyzing the tumor tissue. After GOx/DZ@Cu NPs therapy, the tumor tissue showed the highest level of cell necrosis, apoptosis, as well as the most significant inhibition of proliferation based on H & E, TUNEL, and Ki67 staining, respectively (Fig. 4E). Collectively, all these results demonstrated the superiority of GOx/DZ@Cu for tumor therapy.

The biocompatibility of the nanosystem were evaluated systematically. The body weight of all mice did not change obviously during treatment (Fig. S17 in Supporting information), indicating no acute toxicity. After treatments, several blood biochemical indexes, including liver enzymes alanine transaminase (ALT), aspartate aminotransferase (AST), blood urea nitrogen (BUN), and creatinine (Cre), were within the normal range (Fig. S18A in Supporting information), demonstrating the lack of hepatotoxicity and nephrotoxicity. Moreover, the major organs were further examined by H & E staining (Fig. S18B in Supporting information), and no pathological change was observed, demonstrating the biosafety of the nanoparticles for in vivo applications.

In summary, we report a highly robust Cu NPs as a biomineralized carrier of macromolecules with extremely high loading capacity and pH-responsive drug release profile. Cu2+ was rationally screened from various transition metals based on their properties to biomineralize with CO32− for both nucleic acids and protein loading. Cu NPs was prepared through a simple process to effectively load GOx and DZ as co-delivery system, and facilitate their delivery for tumor accumulation and cell membrane penetration. From therapeutic aspect, GOx/DZ@Cu acted as an all-in-one nanoplatform to exert combinatorial starvation therapy/gene therapy/CDT via co-release of GOx, DZ and Cu2+, achieving excellent anti-tumor effect. Collectively, such biocompatible nanoplatform with facile and cost-effective preparation, robust drug loading, and multiple functionalities shows great promise as a general carrier for micromolecular drugs to promote their clinical translation.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

This work was supported by National Natural Science Foundation of China (Nos. U1903125, 82073799), Natural Science Foundation of Hunan Province in China (No. 2021JJ20084), the Science and Technology Innovation Program of Hunan Province (No. 2021RC3020), Training Program for Excellent Young Innovators of Changsha (No. kq2206057), and the Hunan Provincial Education Commission Foundation (Nos. 19B068, 20A056).

Supplementary material associated with this article can be found, in the online version, at doi:

F. Arcudi, L. Dordevic, M. Prato, Acc. Chem. Res. 52 (2019) 2070-2079.

doi: 10.1021/acs.accounts.9b00249

X.D. Zhang, X.K. Chen, F.G. Wu, Carbon nanodots for cell imaging, in: F.G. Wu (Ed. ), Fluorescent Materials for Cell Imaging, Springer, Singapore, Singapore, 2020, pp. 49-75.

Y.Q. Sun, H.Y. Qin, X. Geng, et al., ACS Appl. Mater. Interfaces 12 (2020) 31738-31744.

doi: 10.1021/acsami.0c05005

X.W. Hua, Y.W. Bao, F.G. Wu, ACS Appl. Mater. Interfaces 10 (2018) 10664-10677.

doi: 10.1021/acsami.7b19549

X.W. Hua, Y.W. Bao, J. Zeng, F.G. Wu, ACS Appl. Mater. Interfaces 11 (2019) 32647-32658.

doi: 10.1021/acsami.9b09590

J.J. Yang, X.D. Zhang, Y.H. Ma, et al., ACS Appl. Mater. Interfaces 8 (2016) 32170-32181.

doi: 10.1021/acsami.6b10398

S. Chen, T.T. Sun, M. Zheng, Z.G. Xie, Adv. Funct. Mater. 30 (2020) 2004680.

doi: 10.1002/adfm.202004680

M.H. Lan, L. Guo, S.J. Zhao, et al., Adv. Therap. 1 (2018) 1800077.

doi: 10.1002/adtp.201800077

H.F. Liu, J. Yang, Z.H. Li, et al., Anal. Chem. 91 (2019) 9259-9265.

doi: 10.1021/acs.analchem.9b02147

S. Sun, Q. Chen, Z.D. Tang, et al., Angew. Chem. Int. Ed. 59 (2020) 21041-21048.

doi: 10.1002/anie.202007786

G. Gao, Y.W. Jiang, H.R. Jia, J.J. Yang, F.G. Wu, Carbon 134 (2018) 232-243.

doi: 10.1016/j.carbon.2018.02.063

J.J. Yang, G. Gao, X.D. Zhang, et al., Carbon 146 (2019) 827-839.

doi: 10.1016/j.carbon.2019.02.040

X. Zhang, J.M. Wang, J. Liu, et al., Carbon 115 (2017) 134-146.

doi: 10.1016/j.carbon.2017.01.005

C.X. Wang, Z.Z. Xu, H. Cheng, et al., Carbon 82 (2015) 87-95.

doi: 10.1016/j.carbon.2014.10.035

N. Wang, Y.T. Wang, T.T. Guo, et al., Biosens. Bioelectron. 85 (2016) 68-75.

doi: 10.1016/j.bios.2016.04.089

S.H. Li, D. Amat, Z.L. Peng, et al., Nanoscale 8 (2016) 16662-16669.

doi: 10.1039/C6NR05055G

T. Feng, X.Z. Ai, G.H. An, P.P. Yang, Y.L. Zhao, ACS Nano 10 (2016) 4410-44120.

doi: 10.1021/acsnano.6b00043

Y.B. Liu, L. Zhou, Y.N. Li, R.P. Deng, H.J. Zhang, Nanoscale 9 (2017) 491-496.

doi: 10.1039/C6NR07123F

M.H. Sun, C. Liang, Z. Tian, et al., J. Phys. Chem. Lett. 10 (2019) 3094-3100.

doi: 10.1021/acs.jpclett.9b00842

Y.F. Huang, X. Zhou, R. Zhou, et al., Chem. Eur. J. 20 (2014) 5640-5648.

doi: 10.1002/chem.201400011

Q. Xu, P. Pu, J.G. Zhao, et al., J. Mater. Chem. A: Mater. Energy Sustain. 3 (2015) 542-546.

doi: 10.1039/C4TA05483K

Z. Zhang, J.H. Hao, J. Zhang, B.L. Zhang, J.L. Tang, RSC Adv. 2 (2012) 8599-8601.

doi: 10.1039/c2ra21217j

J.C. Ge, Q.Y. Jia, W.M. Liu, et al., Adv. Mater. 27 (2015) 4169-4177.

doi: 10.1002/adma.201500323

X.W. Hua, Y.W. Bao, H.Y. Wang, Z. Chen, F.G. Wu, Nanoscale 9 (2017) 2150-2161.

doi: 10.1039/C6NR06558A

K. Jiang, S. Sun, L. Zhang, et al., Angew. Chem. Int. Ed. 54 (2015) 5360-5363.

doi: 10.1002/anie.201501193

Y.Z. Fan, Y. Zhang, N. Li, et al., Sens. Actuators B: Chem. 240 (2017) 949-955.

doi: 10.1016/j.snb.2016.09.063

Z.G. Wang, B.S. Fu, S.W. Zou, et al., Nano Res. 9 (2016) 214-223.

doi: 10.1007/s12274-016-0992-2

S.J. Zhu, Q.N. Meng, L. Wang, et al., Angew. Chem. Int. Ed. 52 (2013) 3953-3957.

doi: 10.1002/anie.201300519

P.L. Li, S. Liu, W.W. Cao, et al., Chem. Commun. (Camb. ) 56 (2020) 2316-2319.

doi: 10.1039/C9CC09223D

P.L. Gao, J.W. Wang, M. Zheng, Z.G. Xie, Chem. Eng. J. 381 (2020)122665.

doi: 10.1016/j.cej.2019.122665

Y.Z. Fu, S.L. Wu, H.K. Zhou, et al., Ind. Eng. Chem. Res. 59 (2020) 1723-1729.

doi: 10.1021/acs.iecr.9b06289

H.H. Ran, X.T. Cheng, Y.W. Bao, et al., J. Mater. Chem. B: Mater. Biol. Med. 7 (2019) 5104-5114.

doi: 10.1039/C9TB00681H

X.Y. Teng, C.G. Ma, C.J. Ge, et al., J. Mater. Chem. B: Mater. Biol. Med. 2 (2014) 4631-4639.

doi: 10.1039/c4tb00368c

P.L. Li, X. Yang, X.H. Zhang, et al., J. Mater. Sci. 55 (2020) 16744-16757.

doi: 10.1007/s10853-020-05262-6

G. Gao, Y.W. Jiang, J.J. Yang, F.G. Wu, Nanoscale 9 (2017) 18368-18378.

doi: 10.1039/C7NR06764J

X.W. Hua, Y.W. Bao, Z. Chen, F.G. Wu, Nanoscale 9 (2017) 10948-10960.

doi: 10.1039/C7NR03658B

J.J. Yang, G. Gao, X.D. Zhang, et al., Nanoscale 9 (2017) 15441-15452.

doi: 10.1039/C7NR05613C

X. Geng, Y.Q. Sun, Z.H. Li, et al., Small 15 (2019) e1901517.

doi: 10.1002/smll.201901517

K.J. Jiang, S.Z. Hu, Y.C. Wang, Z.J. Li, H.W. Lin, Small 16 (2020) e2001909.

doi: 10.1002/smll.202001909

W.Y. Lv, M. Lin, R.S. Li, et al., Chin. Chem. Lett. 30 (2019) 1410-1414.

doi: 10.1016/j.cclet.2019.04.011

W.D. Li, Y. Liu, B.Y. Wang, et al., Chin. Chem. Lett. 30 (2019) 2323-2327.

doi: 10.1016/j.cclet.2019.06.040

B.Y. Wang, J. Li, Z.Y. Tang, B. Yang, S.Y. Lu, Sci. Bull. (Beijing) 64 (2019) 1285-1292.

doi: 10.1016/j.scib.2019.07.021

S.Y. Lu, L.Z. Sui, J.J. Liu, et al., Adv. Mater. 29 (2017) 1603443.

doi: 10.1002/adma.201603443

B. Li, S. Zhao, L. Huang, et al., Chem. Eng. J. 408 (2021) 127245.

doi: 10.1016/j.cej.2020.127245

X.C. Li, S.J. Zhao, B.L. Li, et al., Coord. Chem. Rev. 431 (2020) 213686.

H.Q. Song, X.J. Liu, B.Y. Wang, Z.Y. Tang, S.Y. Lu, Sci. Bull. (Beijing) 64 (2019) 1788-1794.

doi: 10.1016/j.scib.2019.10.006

H. Nie, M.J. Li, Q.S. Li, et al., Chem. Mater. 26 (2014) 3104-3112.

doi: 10.1021/cm5003669

L.L. Pan, S. Sun, A.D. Zhang, et al., Adv. Mater. 27 (2015) 7782-7787.

doi: 10.1002/adma.201503821

A. Sharma, T. Gadly, A. Gupta, et al., J. Phys. Chem. Lett. 7 (2016) 3695-3702.

doi: 10.1021/acs.jpclett.6b01791

B. van Dam, H. Nie, B. Ju, et al., Small 13 (2017) 1702098.

doi: 10.1002/smll.201702098

C. Settembre, A. Fraldi, D.L. Medina, A. Ballabio, Nat. Rev. Mol. Cell Biol. 14 (2013) 283-296.

doi: 10.1038/nrm3565

X.D. Zhang, X.K. Chen, Y.X. Guo, et al., Nanoscale Horiz. 5 (2020) 481-487.

doi: 10.1039/C9NH00643E

X.K. Chen, X.D. Zhang, L.Y. Xia, et al., Nano Lett. 18 (2018) 1159-1167.

doi: 10.1021/acs.nanolett.7b04700

X.K. Chen, X.D. Zhang, F.M. Lin, Y.X. Guo, F.G. Wu, Small 15 (2019) 1901647.

doi: 10.1002/smll.201901647

X.K. Chen, X.D. Zhang, C.C. Li, et al., Sens. Actuators B: Chem. 295 (2019) 49-55.

doi: 10.1016/j.snb.2019.05.031

X.D. Zhang, X.K. Chen, S.Q. Kai, et al., Anal. Chem. 87 (2015) 3360-3365.

doi: 10.1021/ac504520g

L.L. Wu, X.L. Li, Y.F. Ling, C.S. Huang, N.Q. Jia, ACS Appl. Mater. Interfaces 9 (2017) 28222-28232.

doi: 10.1021/acsami.7b08148

D.Y. Zhang, Y. Zheng, H. Zhang, et al., Nanoscale 9 (2017) 18966-18976.

doi: 10.1039/C7NR05349E

Y.Y. He, Z.X. Li, Q.Y. Jia, et al., Chin. Chem. Lett. 28 (2017) 1969-1974.

doi: 10.1016/j.cclet.2017.07.027

E. Shuang, Q.X. Mao, X.L. Yuan, et al., Nanoscale 10 (2018) 12788-12796.

doi: 10.1039/C8NR03453B

Q.Q. Zhang, T. Yang, R.S. Li, et al., Nanoscale 10 (2018) 14705-14711.

doi: 10.1039/C8NR03212B

H.F. Liu, Y.Q. Sun, Z.H. Li, et al., Nanoscale 11 (2019) 8458-8463.

doi: 10.1039/C9NR01678C

S. Chen, Y. Jia, G.Y. Zou, Y.L. Yu, J.H. Wang, Nanoscale 11 (2019) 6377-6383.

doi: 10.1039/C9NR00039A

S.J. Zhao, S.L. Wu, Q.Y. Jia, et al., Chem. Eng. J. 388 (2020) 124212.

doi: 10.1016/j.cej.2020.124212

H.Y. Qin, Y.Q. Sun, X. Geng, et al., Anal. Chim. Acta 1106 (2020) 207-215.

doi: 10.1016/j.aca.2020.02.002

H. Singh, S. Sreedharan, K. Tiwari, et al., Chem. Commun. 55 (2019) 521-524.

doi: 10.1039/C8CC08610A

S. Guo, Y.Q. Sun, X. Geng, et al., J. Mater. Chem. B: Mater. Biol. Med. 8 (2020) 736-742.

doi: 10.1039/C9TB02043H

L.L. Tong, X.X. Wang, Z.Z. Chen, et al., Anal. Chem. 92 (2020) 6430-6436.

doi: 10.1021/acs.analchem.9b05553

S. Hirayama, K. Shobatake, K. Tabayashi, Chem. Phys. Lett. 121 (1985) 228-232.

doi: 10.1016/0009-2614(85)85516-0

A. Gorman, J. Killoran, C. O'Shea, et al., J. Am. Chem. Soc. 126 (2004)10619-10631.

doi: 10.1021/ja047649e

F. Arcudi, L. Dordevic, M. Prato, Acc. Chem. Res. 52 (2019) 2070-2079.

doi: 10.1021/acs.accounts.9b00249

X.D. Zhang, X.K. Chen, F.G. Wu, Carbon nanodots for cell imaging, in: F.G. Wu (Ed. ), Fluorescent Materials for Cell Imaging, Springer, Singapore, Singapore, 2020, pp. 49-75.

Y.Q. Sun, H.Y. Qin, X. Geng, et al., ACS Appl. Mater. Interfaces 12 (2020) 31738-31744.

doi: 10.1021/acsami.0c05005

X.W. Hua, Y.W. Bao, F.G. Wu, ACS Appl. Mater. Interfaces 10 (2018) 10664-10677.

doi: 10.1021/acsami.7b19549

X.W. Hua, Y.W. Bao, J. Zeng, F.G. Wu, ACS Appl. Mater. Interfaces 11 (2019) 32647-32658.

doi: 10.1021/acsami.9b09590

J.J. Yang, X.D. Zhang, Y.H. Ma, et al., ACS Appl. Mater. Interfaces 8 (2016) 32170-32181.

doi: 10.1021/acsami.6b10398

S. Chen, T.T. Sun, M. Zheng, Z.G. Xie, Adv. Funct. Mater. 30 (2020) 2004680.

doi: 10.1002/adfm.202004680

M.H. Lan, L. Guo, S.J. Zhao, et al., Adv. Therap. 1 (2018) 1800077.

doi: 10.1002/adtp.201800077

H.F. Liu, J. Yang, Z.H. Li, et al., Anal. Chem. 91 (2019) 9259-9265.

doi: 10.1021/acs.analchem.9b02147

S. Sun, Q. Chen, Z.D. Tang, et al., Angew. Chem. Int. Ed. 59 (2020) 21041-21048.

doi: 10.1002/anie.202007786

G. Gao, Y.W. Jiang, H.R. Jia, J.J. Yang, F.G. Wu, Carbon 134 (2018) 232-243.

doi: 10.1016/j.carbon.2018.02.063

J.J. Yang, G. Gao, X.D. Zhang, et al., Carbon 146 (2019) 827-839.

doi: 10.1016/j.carbon.2019.02.040

X. Zhang, J.M. Wang, J. Liu, et al., Carbon 115 (2017) 134-146.

doi: 10.1016/j.carbon.2017.01.005

C.X. Wang, Z.Z. Xu, H. Cheng, et al., Carbon 82 (2015) 87-95.

doi: 10.1016/j.carbon.2014.10.035

N. Wang, Y.T. Wang, T.T. Guo, et al., Biosens. Bioelectron. 85 (2016) 68-75.

doi: 10.1016/j.bios.2016.04.089

S.H. Li, D. Amat, Z.L. Peng, et al., Nanoscale 8 (2016) 16662-16669.

doi: 10.1039/C6NR05055G

T. Feng, X.Z. Ai, G.H. An, P.P. Yang, Y.L. Zhao, ACS Nano 10 (2016) 4410-44120.

doi: 10.1021/acsnano.6b00043

Y.B. Liu, L. Zhou, Y.N. Li, R.P. Deng, H.J. Zhang, Nanoscale 9 (2017) 491-496.

doi: 10.1039/C6NR07123F

M.H. Sun, C. Liang, Z. Tian, et al., J. Phys. Chem. Lett. 10 (2019) 3094-3100.

doi: 10.1021/acs.jpclett.9b00842

Y.F. Huang, X. Zhou, R. Zhou, et al., Chem. Eur. J. 20 (2014) 5640-5648.

doi: 10.1002/chem.201400011

Q. Xu, P. Pu, J.G. Zhao, et al., J. Mater. Chem. A: Mater. Energy Sustain. 3 (2015) 542-546.

doi: 10.1039/C4TA05483K

Z. Zhang, J.H. Hao, J. Zhang, B.L. Zhang, J.L. Tang, RSC Adv. 2 (2012) 8599-8601.

doi: 10.1039/c2ra21217j

J.C. Ge, Q.Y. Jia, W.M. Liu, et al., Adv. Mater. 27 (2015) 4169-4177.

doi: 10.1002/adma.201500323

X.W. Hua, Y.W. Bao, H.Y. Wang, Z. Chen, F.G. Wu, Nanoscale 9 (2017) 2150-2161.

doi: 10.1039/C6NR06558A

K. Jiang, S. Sun, L. Zhang, et al., Angew. Chem. Int. Ed. 54 (2015) 5360-5363.

doi: 10.1002/anie.201501193

Y.Z. Fan, Y. Zhang, N. Li, et al., Sens. Actuators B: Chem. 240 (2017) 949-955.

doi: 10.1016/j.snb.2016.09.063

Z.G. Wang, B.S. Fu, S.W. Zou, et al., Nano Res. 9 (2016) 214-223.

doi: 10.1007/s12274-016-0992-2

S.J. Zhu, Q.N. Meng, L. Wang, et al., Angew. Chem. Int. Ed. 52 (2013) 3953-3957.

doi: 10.1002/anie.201300519

P.L. Li, S. Liu, W.W. Cao, et al., Chem. Commun. (Camb. ) 56 (2020) 2316-2319.

doi: 10.1039/C9CC09223D

P.L. Gao, J.W. Wang, M. Zheng, Z.G. Xie, Chem. Eng. J. 381 (2020)122665.

doi: 10.1016/j.cej.2019.122665

Y.Z. Fu, S.L. Wu, H.K. Zhou, et al., Ind. Eng. Chem. Res. 59 (2020) 1723-1729.

doi: 10.1021/acs.iecr.9b06289

H.H. Ran, X.T. Cheng, Y.W. Bao, et al., J. Mater. Chem. B: Mater. Biol. Med. 7 (2019) 5104-5114.

doi: 10.1039/C9TB00681H

X.Y. Teng, C.G. Ma, C.J. Ge, et al., J. Mater. Chem. B: Mater. Biol. Med. 2 (2014) 4631-4639.

doi: 10.1039/c4tb00368c

P.L. Li, X. Yang, X.H. Zhang, et al., J. Mater. Sci. 55 (2020) 16744-16757.

doi: 10.1007/s10853-020-05262-6

G. Gao, Y.W. Jiang, J.J. Yang, F.G. Wu, Nanoscale 9 (2017) 18368-18378.

doi: 10.1039/C7NR06764J

X.W. Hua, Y.W. Bao, Z. Chen, F.G. Wu, Nanoscale 9 (2017) 10948-10960.

doi: 10.1039/C7NR03658B

J.J. Yang, G. Gao, X.D. Zhang, et al., Nanoscale 9 (2017) 15441-15452.

doi: 10.1039/C7NR05613C

X. Geng, Y.Q. Sun, Z.H. Li, et al., Small 15 (2019) e1901517.

doi: 10.1002/smll.201901517

K.J. Jiang, S.Z. Hu, Y.C. Wang, Z.J. Li, H.W. Lin, Small 16 (2020) e2001909.

doi: 10.1002/smll.202001909

W.Y. Lv, M. Lin, R.S. Li, et al., Chin. Chem. Lett. 30 (2019) 1410-1414.

doi: 10.1016/j.cclet.2019.04.011

W.D. Li, Y. Liu, B.Y. Wang, et al., Chin. Chem. Lett. 30 (2019) 2323-2327.

doi: 10.1016/j.cclet.2019.06.040

B.Y. Wang, J. Li, Z.Y. Tang, B. Yang, S.Y. Lu, Sci. Bull. (Beijing) 64 (2019) 1285-1292.

doi: 10.1016/j.scib.2019.07.021

S.Y. Lu, L.Z. Sui, J.J. Liu, et al., Adv. Mater. 29 (2017) 1603443.

doi: 10.1002/adma.201603443

B. Li, S. Zhao, L. Huang, et al., Chem. Eng. J. 408 (2021) 127245.

doi: 10.1016/j.cej.2020.127245

X.C. Li, S.J. Zhao, B.L. Li, et al., Coord. Chem. Rev. 431 (2020) 213686.

H.Q. Song, X.J. Liu, B.Y. Wang, Z.Y. Tang, S.Y. Lu, Sci. Bull. (Beijing) 64 (2019) 1788-1794.

doi: 10.1016/j.scib.2019.10.006

H. Nie, M.J. Li, Q.S. Li, et al., Chem. Mater. 26 (2014) 3104-3112.

doi: 10.1021/cm5003669

L.L. Pan, S. Sun, A.D. Zhang, et al., Adv. Mater. 27 (2015) 7782-7787.

doi: 10.1002/adma.201503821

A. Sharma, T. Gadly, A. Gupta, et al., J. Phys. Chem. Lett. 7 (2016) 3695-3702.

doi: 10.1021/acs.jpclett.6b01791

B. van Dam, H. Nie, B. Ju, et al., Small 13 (2017) 1702098.

doi: 10.1002/smll.201702098

C. Settembre, A. Fraldi, D.L. Medina, A. Ballabio, Nat. Rev. Mol. Cell Biol. 14 (2013) 283-296.

doi: 10.1038/nrm3565

X.D. Zhang, X.K. Chen, Y.X. Guo, et al., Nanoscale Horiz. 5 (2020) 481-487.

doi: 10.1039/C9NH00643E

X.K. Chen, X.D. Zhang, L.Y. Xia, et al., Nano Lett. 18 (2018) 1159-1167.

doi: 10.1021/acs.nanolett.7b04700

X.K. Chen, X.D. Zhang, F.M. Lin, Y.X. Guo, F.G. Wu, Small 15 (2019) 1901647.

doi: 10.1002/smll.201901647

X.K. Chen, X.D. Zhang, C.C. Li, et al., Sens. Actuators B: Chem. 295 (2019) 49-55.

doi: 10.1016/j.snb.2019.05.031

X.D. Zhang, X.K. Chen, S.Q. Kai, et al., Anal. Chem. 87 (2015) 3360-3365.

doi: 10.1021/ac504520g

L.L. Wu, X.L. Li, Y.F. Ling, C.S. Huang, N.Q. Jia, ACS Appl. Mater. Interfaces 9 (2017) 28222-28232.

doi: 10.1021/acsami.7b08148

D.Y. Zhang, Y. Zheng, H. Zhang, et al., Nanoscale 9 (2017) 18966-18976.

doi: 10.1039/C7NR05349E

Y.Y. He, Z.X. Li, Q.Y. Jia, et al., Chin. Chem. Lett. 28 (2017) 1969-1974.

doi: 10.1016/j.cclet.2017.07.027

E. Shuang, Q.X. Mao, X.L. Yuan, et al., Nanoscale 10 (2018) 12788-12796.

doi: 10.1039/C8NR03453B

Q.Q. Zhang, T. Yang, R.S. Li, et al., Nanoscale 10 (2018) 14705-14711.

doi: 10.1039/C8NR03212B

H.F. Liu, Y.Q. Sun, Z.H. Li, et al., Nanoscale 11 (2019) 8458-8463.

doi: 10.1039/C9NR01678C

S. Chen, Y. Jia, G.Y. Zou, Y.L. Yu, J.H. Wang, Nanoscale 11 (2019) 6377-6383.

doi: 10.1039/C9NR00039A

S.J. Zhao, S.L. Wu, Q.Y. Jia, et al., Chem. Eng. J. 388 (2020) 124212.

doi: 10.1016/j.cej.2020.124212

H.Y. Qin, Y.Q. Sun, X. Geng, et al., Anal. Chim. Acta 1106 (2020) 207-215.

doi: 10.1016/j.aca.2020.02.002

H. Singh, S. Sreedharan, K. Tiwari, et al., Chem. Commun. 55 (2019) 521-524.

doi: 10.1039/C8CC08610A

S. Guo, Y.Q. Sun, X. Geng, et al., J. Mater. Chem. B: Mater. Biol. Med. 8 (2020) 736-742.

doi: 10.1039/C9TB02043H

L.L. Tong, X.X. Wang, Z.Z. Chen, et al., Anal. Chem. 92 (2020) 6430-6436.

doi: 10.1021/acs.analchem.9b05553

S. Hirayama, K. Shobatake, K. Tabayashi, Chem. Phys. Lett. 121 (1985) 228-232.

doi: 10.1016/0009-2614(85)85516-0

A. Gorman, J. Killoran, C. O'Shea, et al., J. Am. Chem. Soc. 126 (2004)10619-10631.

doi: 10.1021/ja047649e

Boran Cheng , Lei Cao , Chen Li , Fang-Yi Huo , Qian-Fang Meng , Ganglin Tong , Xuan Wu , Lin-Lin Bu , Lang Rao , Shubin Wang . Fluorine-doped carbon quantum dots with deep-red emission for hypochlorite determination and cancer cell imaging. Chinese Chemical Letters, 2024, 35(6): 108969-. doi: 10.1016/j.cclet.2023.108969

Xu Qu , Pengzhao Wu , Kaixuan Duan , Guangwei Wang , Liang-Liang Gao , Yuan Guo , Jianjian Zhang , Donglei Shi . Self-calibrating probes constructed on a unique dual-emissive fluorescence platform for the precise tracking of cellular senescence. Chinese Chemical Letters, 2024, 35(12): 109681-. doi: 10.1016/j.cclet.2024.109681

Qian Ren , Xue Dai , Ran Cen , Yang Luo , Mingyang Li , Ziyun Zhang , Qinghong Bai , Zhu Tao , Xin Xiao . A cucurbit[8]uril-based supramolecular phosphorescent assembly: Cell imaging and sensing of amino acids in aqueous solution. Chinese Chemical Letters, 2024, 35(12): 110022-. doi: 10.1016/j.cclet.2024.110022

Shuangying Li , Qingxiang Zhou , Zhi Li , Menghua Liu , Yanhui Li . Sensitive measurement of silver ions in environmental water samples integrating magnetic ion-imprinted solid phase extraction and carbon dot fluorescent sensor. Chinese Chemical Letters, 2024, 35(5): 108693-. doi: 10.1016/j.cclet.2023.108693

Yupeng Liu , Hui Wang , Songnan Qu . Review on near-infrared absorbing/emissive carbon dots: From preparation to multi-functional application. Chinese Chemical Letters, 2025, 36(5): 110618-. doi: 10.1016/j.cclet.2024.110618

Chenghao Liu , Xiaofeng Lin , Jing Liao , Min Yang , Min Jiang , Yue Huang , Zhizhi Du , Lina Chen , Sanjun Fan , Qitong Huang . Carbon dots-based dopamine sensors: Recent advances and challenges. Chinese Chemical Letters, 2024, 35(12): 109598-. doi: 10.1016/j.cclet.2024.109598

Quan Zhang , Shunjie Xing , Jingqian Han , Li Feng , Jianchun Li , Zhaosheng Qian , Jin Zhou . Organic pollutant sensing for human health based on carbon dots. Chinese Chemical Letters, 2025, 36(1): 110117-. doi: 10.1016/j.cclet.2024.110117

Qiang Fu , Shouhong Sun , Kangzhi Lu , Ning Li , Zhanhua Dong . Boron-doped carbon dots: Doping strategies, performance effects, and applications. Chinese Chemical Letters, 2024, 35(7): 109136-. doi: 10.1016/j.cclet.2023.109136

Yuan Liu , Boyang Wang , Yaxin Li , Weidong Li , Siyu Lu . Understanding excitonic behavior and electroluminescence light emitting diode application of carbon dots. Chinese Chemical Letters, 2025, 36(2): 110426-. doi: 10.1016/j.cclet.2024.110426

Jianye Kang , Xinyu Yang , Xuhao Yang , Jiahui Sun , Yuhang Liu , Shutao Wang , Wenlong Song . Carbon dots-enhanced pH-responsive lubricating hydrogel based on reversible dynamic covalent bondings. Chinese Chemical Letters, 2024, 35(5): 109297-. doi: 10.1016/j.cclet.2023.109297

Meiling Xu , Xinyang Li , Pengyuan Liu , Junjun Liu , Xiao Han , Guodong Chai , Shuangling Zhong , Bai Yang , Liying Cui . A novel and visible ratiometric fluorescence determination of carbaryl based on red emissive carbon dots by a solvent-free method. Chinese Chemical Letters, 2025, 36(2): 109860-. doi: 10.1016/j.cclet.2024.109860

Rui Cheng , Tingting Zhang , Xin Huang , Jian Yu . Facile synthesis of high-brightness green-emitting carbon dots with narrow bandwidth towards backlight display. Chinese Chemical Letters, 2024, 35(5): 108763-. doi: 10.1016/j.cclet.2023.108763

Wu-Jian Long , Yang Yu , Chuang He . A novel and promising engineering application of carbon dots: Enhancing the chloride binding performance of cement. Chinese Chemical Letters, 2024, 35(6): 108943-. doi: 10.1016/j.cclet.2023.108943

Qiang Li , Jiangbo Fan , Hongkai Mu , Lin Chen , Yongzhen Yang , Shiping Yu . Nucleus-targeting orange-emissive carbon dots delivery adriamycin for enhanced anti-liver cancer therapy. Chinese Chemical Letters, 2024, 35(6): 108947-. doi: 10.1016/j.cclet.2023.108947

Xiaoning Li , Quanyu Shi , Meng Li , Ningxin Song , Yumeng Xiao , Huining Xiao , Tony D. James , Lei Feng . Functionalization of cellulose carbon dots with different elements (N, B and S) for mercury ion detection and anti-counterfeit applications. Chinese Chemical Letters, 2024, 35(7): 109021-. doi: 10.1016/j.cclet.2023.109021

Hao Cai , Xiaoyan Wu , Lei Jiang , Feng Yu , Yuxiang Yang , Yan Li , Xian Zhang , Jian Liu , Zijian Li , Hong Bi . Lysosome-targeted carbon dots with a light-controlled nitric oxide releasing property for enhanced photodynamic therapy. Chinese Chemical Letters, 2024, 35(4): 108946-. doi: 10.1016/j.cclet.2023.108946

Liwen Wang , Boyang Wang , Siyu Lu , Shubo Lv , Xiaoli Qu . High quantum yield yellow emission carbon dots for the construction of blue light blocking films. Chinese Chemical Letters, 2025, 36(2): 110497-. doi: 10.1016/j.cclet.2024.110497

Rui Cheng , Xin Huang , Tingting Zhang , Jiazhuang Guo , Jian Yu , Su Chen . Solid superacid catalysts promote high-performance carbon dots with narrow-band fluorescence emission for luminescence solar concentrators. Chinese Chemical Letters, 2024, 35(8): 109278-. doi: 10.1016/j.cclet.2023.109278

Xiuzheng Deng , Changhai Liu , Xiaotong Yan , Jingshan Fan , Qian Liang , Zhongyu Li . Carbon dots anchored NiAl-LDH@In2O3 hierarchical nanotubes for promoting selective CO2 photoreduction into CH4. Chinese Chemical Letters, 2024, 35(6): 108942-. doi: 10.1016/j.cclet.2023.108942

Binyang Qin , Mengqi Wang , Shimei Wu , Yining Li , Chilin Liu , Yufei Zhang , Haosen Fan . Carbon dots confined nanosheets assembled NiCo2S4@CDs cross-stacked architecture for enhanced sodium ion storage. Chinese Chemical Letters, 2024, 35(7): 108921-. doi: 10.1016/j.cclet.2023.108921