Temperature stability of symmetric activated carbon supercapacitors assembled with in situ electrodeposited poly(vinyl alcohol) potassium borate hydrogel electrolyte

- Corresponding author: Jiang Mengjin, memoggy@126.com

Citation:

Lv Wanwan, Xue Runping, Chen Sheng, Jiang Mengjin. Temperature stability of symmetric activated carbon supercapacitors assembled with in situ electrodeposited poly(vinyl alcohol) potassium borate hydrogel electrolyte[J]. Chinese Chemical Letters,

;2018, 29(4): 637-640.

doi:

10.1016/j.cclet.2017.11.035

Attribute to high power density, and long cycle life, electric double-layer capacitors (EDLCs) or supercapacitors (SCs) are becoming very promising in the fields that need high power output, such as electric vehicles, and military equipment [1-4]. Nowadays, most electrolytes for commercial SCs use organic solvents such as acetonitrile (AN) for the wider electrochemical stability voltage window which offers a higher energy density and better cycle stability [5, 6]. However, the ionic conductivity of the organic electrolyte is not satisfied, which leads to the relatively high equivalent series resistance (ESR) and low power density of the SCs. Also, most organic electrolytes are poisonous, flammable, expensive, and ecologically unfriendly. Moreover, organic electrolytes need specific, severe manufacturing conditions (strict waterfree and oxygen-free conditions). As a contrast, aqueous electrolytes are nonflammable, nontoxic, environmentally friendly, and low-costed. Their high ionic conductivity and small ion size endow aqueous SCs with excellent electrochemical performances (high specific capacitance, low ESR, and high power density), which fulfill the needs of future development of SCs [7, 8].

Nevertheless, aqueous electrolytes have a narrow electrochemical window (most of them ≤ 1.23 V) [9], which limits the energy density and the practical applications of aqueous SCs. Therefore, many research focused on improving the electrochemical stability of aqueous electrolytes. The neutral salt solutions such as Li2SO4 [10, 11], Na2SO4 [12, 13], and KCl [14] were proved to be able to run at higher voltages than aqueous acidic or alkali electrolytes. However, subject to the strong hydration of the ions, the rate performances of SCs using these neutral salts solutions are not satisfying [15]. Most recently, a kind of in situ electrodeposited poly (vinyl alcohol) potassium borate (PVAPB) hydrogel electrolyte (HGE) with excellent electrochemical stability was developed [16, 17]. It showed not only high operation voltage (2 V) but also excellent rate performance in the symmetric activated carbon (AC) SCs. The HGE structure also avoided the weaknesses of liquid aqueous electrolytes (internal corrosion, leaking, and complicate packaging), and made it possible to build flexible SCs.

Besides the electrochemical performance, the temperature stability was another important property of electrolytes, which directly affected the operating temperature range of SCs. The liquid electrolytes would be inactive when their solvents began to freeze or boil. Therefore, the operating temperature range of liquid electrolytes was mainly determined by the solvents they used [18].The freezing point of water is higher than those of most organic solvents, so the low-temperature stability of most aqueous electrolytes are inferior to those of organic electrolytes [8]. As to the HGEs, the states of water in them are not the same as those of water in liquid aqueous electrolytes, and some polymer gel skeletons are not stable in certain temperature ranges, so their temperature failure mechanisms might be different from those of normal liquid aqueous electrolytes [19].

As a new high voltage HGEs for SCs, the PVAPB HGE presents an exceptional ionic transport mechanism, and the water molecules in PVAPB HGE was speculated to ionize and restore during charging and discharging processes of SCs [17]. Thus, the temperature stability of PVAPB HGE might be quite different from those of liquid aqueous electrolytes. In this study, the AC/PVAPB HGE/AC SCs were fabricated and tested at various temperatures (from -5 ℃ to 80 ℃). The results were compared with the SCs using liquid aqueous electrolytes to examine the temperature stability of PVAPB HGEs.

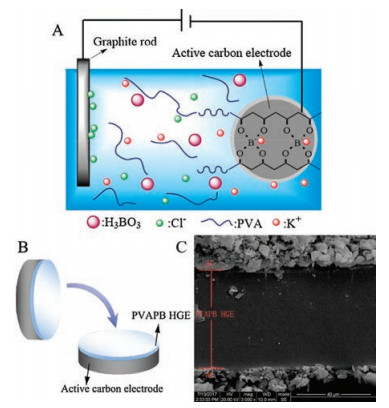

The AC/PVAPB HGE/AC SCs were fabricated according to the following steps. First, PVA (10 g), boric acid (1.75 g), KCl (33.55 g, 0.45 mol) were dissolved in about 450 mL deionized water at 95 ℃. Then the solution was cooling down to 40 ℃, and additional deionized water was added to form 500 mL electrodeposition solutions with 0.9 mol/L of K+ ions. Then the AC electrodes were immersed in this electrodeposition solution, and cathodic electrodeposited with graphite rode anode at 2.75 V for 3 min. As a result, PVAPB HGEs were prepared on the surface of AC electrodes, as shown in Fig. 1A. After electrodeposition, the surfaces of wet PVAPB HGEs were treated with dry filter paper to remove excessive electrodeposition solution. Finally, AC electrodes covered with PVAPB HGEs were assembled into CR 2032 coin-type cell to build symmetric SCs. During the cell assembling, the two working electrodes were placed with the sides covered with PVAPB HGEs facing each other. No additional separator or liquid electrolyte was added during cell assembling, as shown in Fig. 1B. For comparison, the SCs control samples were prepared by using 0.9 mol/L KCl aqueous solution (the same KCl concentration was used in preparing the PVAPB HGEs) and 1 mol/L Na2SO4 aqueous solution (the widely used electrolyte in aqueous high-voltage SCs) as the liquid electrolytes and glass microfiber membrane as the separator.

The cross-section morphology structure of PVAPB HGE between the two AC electrodes was observed with JSM-5900LV scanning electron microscopy (SEM) (JEOL Ltd., Japan). And its SEM image was shown in Fig. 1C. It was found that the PVAPB HGE layer was smooth and intact with the thickness of about 50 μm. The PVAPB HGE closely attached on the AC electrode, and the interface between them was tight and compact, which could provide the SCs with low interface resistance and good electrochemical performance.

The stability of aqueous SCs at low temperature mainly depends on the freezing point of the electrolyte. Therefore, The PVAPB HGE and the liquid electrolytes (0.9 mol/L KCl and 1 mol/L Na2SO4) were analyzed with differential scanning calorimetry (DSC) (NETZSCH DSC 204 F1, Germany) to observe their temperature stability. DSC samples (5–8 mg) were sealed in aluminum pans and then cooled to -40 ℃ at a rate of 10 ℃/min in a nitrogen atmosphere. After the freezing process, the samples were heated to 40 ℃ at a speed of 2 ℃/min. DSC diagrams of PVAPB HGE, 0.9 mol/L KCl, and 1 mol/L Na2SO4 electrolytes were shown in Fig. 2 to compare their thermal properties at low temperature. There was one endothermic peak at about 0.57 ℃ in DSC diagram of 1 mol/L Na2SO4 solution, which was attributed to the fact that saturated Na2SO4 solution would hardly change the freezing point of water [20]. By contrast, KCl salt had a higher solubility than Na2SO4 salt in water at low temperature, resulting in the phenomenon that the addition of KCl salt would obviously impact on the freezing point of water. There were two endothermic peaks at about -8.7 ℃ and -1.9 ℃ in the DSC diagram of 0.9 mol/L KCl solution. The peak at -8.7 ℃ was attributed to the freezing of water molecules that interacted with K+ and Cl- ions, and that at -1.9 ℃ indicated the free water molecules in 0.9 mol/L KCl solution. As for PVAPB HGE, There was only one endothermic peak at about -9.4 ℃ in its DSC diagram, which was different from that of 0.9 mol/L KCl solution. It indicates that the water molecules in PVAPB HGEs are mainly in bonding state. These bonding water molecules produced by the strong hydrogen bond interaction between water molecules and PVA in PVAPB HGEs may not even be frozen, which can reduce the freezing point of PVAPB HGE. The lowest freezing point of PVAPB HGE suggested that it should be more stable than other liquid aqueous electrolytes at low temperature.

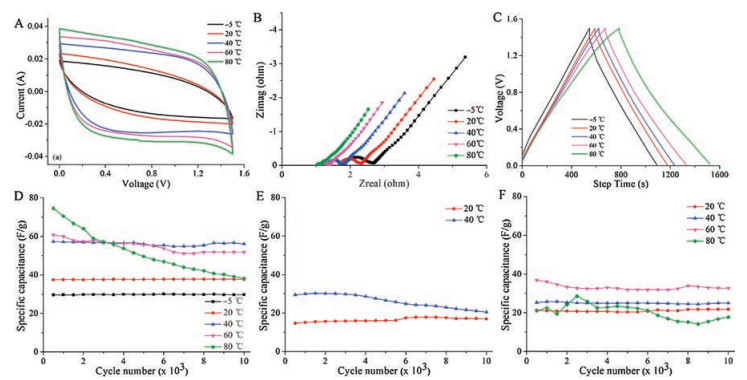

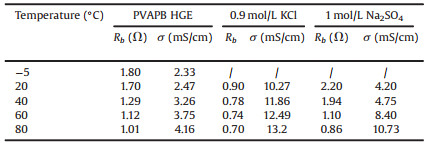

The electrochemical performances of the SCs using different aqueous electrolytes were all evaluated from -5 ℃ to 80 ℃. The test voltage ranges were set as 0–1.5 V for PVAPB HGE and 1 mol/L Na2SO4, and 0–1.1 V for 0.9 mol/L KCl (because of its relatively narrow electrochemical window). Cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) measurements were carried out by the CHI660E electrochemical workstation. The charge-discharge tests were performed on LANHE CT2001A supercapacitor test system. The SC samples were kept at the experimental temperatures for 2 h before tests to accomplish the temperature equilibrium. It could be seen from Fig. 3A that the CV curves of the PVAPB HGE SCs had a much better rectangular profile than those of SCs with liquid aqueous electrolytes (Fig. S1 in Supporting information), which indicated its better capacitive behavior. With the increase of the operating temperature, the specific capacitance of all the SCs increased, and the specific capacitance of the SC assembled with PVAPB HGE was greater than those of the SCs assembled with liquid aqueous electrolytes. All the SCs would lose function below -5 ℃ or beyond 80 ℃. The SCs using PVAPB HGEs could stably operate from -5 ℃ to 80 ℃, but the SCs with 0.9 mol/L KCl and 1 mol/L Na2SO4 stopped working at -5 ℃, which indicated that the low-temperature stability of PVAPB HGE was better than those liquid aqueous electrolytes because of the unique bonding state of water molecules in PVAPB HGE. Fig. 3B showed the Nyquist plots of the PVAPB HGE SCs measured from 106 Hz to 10-1 Hz at different temperatures, which displayed a typical capacitive behavior. It was found that the bulk resistances (Rb) of PVAPB HGE is higher than that of 0.9 mol/L KCl but smaller than that of 1 mol/L Na2SO4 (Fig. S2 in Supporting information). The Rb and the charge transfer resistances (Rct) of all the SCs decreased with the increase of temperature. It could be seen that the Rb and Rct of SCs using 1 mol/L Na2SO4 were most sensitively affected by the temperature, while those of SCs using 0.9 mol/L KCl seemed insensitive to the temperature, and the influence of the temperatures on the SCs using PVAPB HGE was medium. These phenomena can be explained by the hydration of ions in the electrolytes. The hydrated ions are very sensitive to the temperature, and high temperature will lower the hydration numbers of ions, which is a benefit for the mobility of the ions. Na2SO4 has stronger hydration than KCl, so its ionic conductivity is more temperature-sensitive than that of KCl. The ions in PVAPB HGE cannot be simply described as hydrated ions, but the result still indicated that higher temperature is more suitable for the ion mobility in the PVAPB HGE.

The ionic conductivity σ of electrolytes at different temperatures can be calculated as follows:

|

|

Where A is the surface area of electrodes; d is the distance between the positive and negative electrodes (the thickness of the PVAPB HGE, KCl electrolyte, and the Na2SO4 electrolyte is about 50 μm, 110 μm, and 110 μm, respectively.); Rb is the bulk resistances of the electrolytes. The Rb and σ calculated from Fig. 3B and Fig. S2 were shown in Table 1.

|

The temperature dependence of the conductivity of electrolyte follow the Arrhenius equation: σ = σ0exp(-Ea/RT), where σ0 is the pre-exponential factor; Ea is the activation energy; T is the absolute temperature, and R is the gas constant. The plot of lnσ versus 1/T for three kinds of electrolytes was shown in Fig. S3 (Supporting information). From the slope of the linear fit line of lnσ versus 1/T plot, the Ea of PVAPB HGE, 0.9 mol/L KCl, and 1 mol/L Na2SO4 were calculated to be 5.81 kJ/mol, 3.52 kJ/mol and 14.44 kJ/mol, respectively. The relatively low Ea of PVAPB HGE indicates its excellent temperature stability. The galvanostatic charge-discharge curves of PVAPB HGE SCs in Fig. 3C behave as a mirror-like shape during the charge-discharge process, which means that the SCs using PVAPB HGEs own a favorable electrochemical capacitance performance in wide temperature region. However, the charge-discharge curves of SCs using liquid aqueous electrolytes (Fig. S4 in Supporting information) show distorted shapes especially at low temperatures, which indicates their poor reversibility at low temperatures. It is noticeable that the SCs using 0.9 mol/L KCl failed in the galvanostatic charge-discharge test at 60 ℃ and 80 ℃, though it could run in the CV test at the same temperatures. The reason comes from that the activity of the water molecules in 0.9 mol/L KCl solution increased at high temperature, which lowers down its electrochemical stability and made 0.9 mol/L KCl SCs stop running at high temperature [21]. The water molecules in 1 mol/L Na2SO4 also has a similar tendency at high temperature, but the strong hydration of Na2SO4 salt could still keep its electrolyte stable at 60 ℃ and 80 ℃.

The long-term cycle performance tests were employed at the current density of 0.5 A/g from -5 ℃ to 80 ℃ to further examine the stability of the SCs at different temperatures. Results were shown in Figs. 3D–F. It was found that 0.9 mol/L KCl SCs had relatively low specific capacitance and poor cycle performance, compared with PVAPB HGE SCs and 1 mol/L Na2SO4 SCs. Although the cyclic stability of 1 mol/L Na2SO4 SCs was as good as that of PVAPB HGE SCs, its specific capacitance was far lower than that of PVAPB HGE SCs. The capacitance of both PVAPB HGE SCs and Na2SO4 SCs dropped a lot during cycle test at 80 ℃, which may be caused by the drastic water evaporation at 80 ℃ in the electrolyte. The capacitance attenuation of the PVAPB HGE SCs was hardly observed at -5 ℃, 20 ℃, and 40 ℃, which indicates its excellent reversibility in wide temperature range, and potential application in the relatively extreme environment.

In summary, the electrochemical performance of the AC/AC SCs assembled with in situ electrodeposited PVAPB HGEs, and liquid aqueous electrolytes (0.9 mol/L KCl and 1 mol/L Na2SO4) were systematically studied in a wide temperature range from -5 ℃ to 80 ℃. In general, as a new aqueous electrolyte, the PVAPB HGE presents better temperature stability than traditional liquid aqueous electrolytes in symmetric AC/AC supercapacitors. Compared with liquid aqueous electrolytes (0.9 mol/L KCl and 1 mol/L Na2SO4) SCs, PVAPB HGE SCs possessed higher specific capacitance in the operating temperature range from -5 ℃ to 80 ℃. The activation energy of ionic conductivity of PVAPB HGE was calculated to be 5.81 kJ/mol, indicating its temperature-insensitivity, and stable electrochemical performance in a wide temperature range. The PVAPB HGE SCs also show good cycle performance at a temperature range from -5 ℃ to 60 ℃, which is better than those of SCs using liquid aqueous electrolytes. The excellent temperature stability of PVAPB HGE made it possible be used in the harsh temperature environment with which traditional liquid aqueous electrolyte can not meet.

Supplementary data associated with this article can be found, in the online version, at https://doi.org/10.1016/j.cclet.2017.11.035.

N. Jha, P. Ramesh, E. Bekyarova, M.E. Itkis, R.C. Haddon, Adv. Energy Mater. 2(2012) 438-444.

doi: 10.1002/aenm.v2.4

A. Burke, Electrochim. Acta 53(2007) 1083-1091.

doi: 10.1016/j.electacta.2007.01.011

P. Simon, Y. Gogotsi, Nat. Mater. 7(2008) 845-854.

doi: 10.1038/nmat2297

K. Hung, C. Masarapu, T. Ko, B. Wei, J. Power Sources 193(2009) 944-949.

doi: 10.1016/j.jpowsour.2009.01.083

P. Liu, M. Verbrugge, S. Soukiazian, J. Power Sources 156(2006) 712-718.

doi: 10.1016/j.jpowsour.2005.05.055

F. Cheng, X. Yu, J. Wang, Z. Shi, C. Wu, Electrochim. Acta 200(2016) 106-114.

doi: 10.1016/j.electacta.2016.03.113

V. Ruiz, R. Santamaría, M. Granda, C. Blanco, Electrochim. Acta 54(2009) 4481-4486.

doi: 10.1016/j.electacta.2009.03.024

R. Vellacheri, A. Al-Haddad, H. Zhao, et al., Nano Energy 8(2014) 231-237.

doi: 10.1016/j.nanoen.2014.06.015

R. Kötz, M. Carlen, Electrochim. Acta 45(2000) 2483-2498.

doi: 10.1016/S0013-4686(00)00354-6

C.H. Mi, X.G. Zhang, H.L. Li, J. Electroanal. Chem. 602(2007) 245-254.

doi: 10.1016/j.jelechem.2007.01.007

W. Tang, L. Liu, S. Tian, et al., Chem. Commun. 47(2011) 10058-10060.

doi: 10.1039/c1cc13474d

L. Demarconnay, E. Raymundo-Piñero, F. Béguin, Electrochem. Commun. 12(2010) 1275-1278.

doi: 10.1016/j.elecom.2010.06.036

L. Athouël, F. Moser, R. Dugas, et al., J. Phys. Chem. C 112(2008) 7270-7277.

doi: 10.1021/jp0773029

M.S. Hong, S.H. Lee, S.W. Kim, Electrochem. Solid-State Lett. 5(2002) A227-A230.

doi: 10.1149/1.1506463

Q. Qu, P. Zhang, B. Wang, et al., J. Phys. Chem. C 113(2009) 14020-14027.

doi: 10.1021/jp8113094

M. Jiang, J. Zhu, C. Chen, et al., ACS Appl. Mater. Interfaces 8(2016) 3473-3481.

doi: 10.1021/acsami.5b11984

M. Jiang, J. Zhu, C. Chen, et al., J. Mater. Chem. A 4(2016) 16588-16596.

doi: 10.1039/C6TA07063A

E. Iwama, P.L. Taberna, P. Azais, L. Brégeon, P. Simon, J. Power Sources 219(2012) 235-239.

doi: 10.1016/j.jpowsour.2012.07.029

D.Z. Chen, J. Yu, W. Lu, et al., Electrochim. Acta 233(2017) 181-189.

doi: 10.1016/j.electacta.2017.03.009

M. Steiger, S. Asmussen, Geochim. Cosmochim. Acta 72(2008) 4291-4306.

doi: 10.1016/j.gca.2008.05.053

A.A. Łatoszyńska, P.L. Taberna, P. Simon, W. Wieczorek, Electrochim. Acta 242(2017) 31-37.

doi: 10.1016/j.electacta.2017.04.122

N. Jha, P. Ramesh, E. Bekyarova, M.E. Itkis, R.C. Haddon, Adv. Energy Mater. 2(2012) 438-444.

doi: 10.1002/aenm.v2.4

A. Burke, Electrochim. Acta 53(2007) 1083-1091.

doi: 10.1016/j.electacta.2007.01.011

P. Simon, Y. Gogotsi, Nat. Mater. 7(2008) 845-854.

doi: 10.1038/nmat2297

K. Hung, C. Masarapu, T. Ko, B. Wei, J. Power Sources 193(2009) 944-949.

doi: 10.1016/j.jpowsour.2009.01.083

P. Liu, M. Verbrugge, S. Soukiazian, J. Power Sources 156(2006) 712-718.

doi: 10.1016/j.jpowsour.2005.05.055

F. Cheng, X. Yu, J. Wang, Z. Shi, C. Wu, Electrochim. Acta 200(2016) 106-114.

doi: 10.1016/j.electacta.2016.03.113

V. Ruiz, R. Santamaría, M. Granda, C. Blanco, Electrochim. Acta 54(2009) 4481-4486.

doi: 10.1016/j.electacta.2009.03.024

R. Vellacheri, A. Al-Haddad, H. Zhao, et al., Nano Energy 8(2014) 231-237.

doi: 10.1016/j.nanoen.2014.06.015

R. Kötz, M. Carlen, Electrochim. Acta 45(2000) 2483-2498.

doi: 10.1016/S0013-4686(00)00354-6

C.H. Mi, X.G. Zhang, H.L. Li, J. Electroanal. Chem. 602(2007) 245-254.

doi: 10.1016/j.jelechem.2007.01.007

W. Tang, L. Liu, S. Tian, et al., Chem. Commun. 47(2011) 10058-10060.

doi: 10.1039/c1cc13474d

L. Demarconnay, E. Raymundo-Piñero, F. Béguin, Electrochem. Commun. 12(2010) 1275-1278.

doi: 10.1016/j.elecom.2010.06.036

L. Athouël, F. Moser, R. Dugas, et al., J. Phys. Chem. C 112(2008) 7270-7277.

doi: 10.1021/jp0773029

M.S. Hong, S.H. Lee, S.W. Kim, Electrochem. Solid-State Lett. 5(2002) A227-A230.

doi: 10.1149/1.1506463

Q. Qu, P. Zhang, B. Wang, et al., J. Phys. Chem. C 113(2009) 14020-14027.

doi: 10.1021/jp8113094

M. Jiang, J. Zhu, C. Chen, et al., ACS Appl. Mater. Interfaces 8(2016) 3473-3481.

doi: 10.1021/acsami.5b11984

M. Jiang, J. Zhu, C. Chen, et al., J. Mater. Chem. A 4(2016) 16588-16596.

doi: 10.1039/C6TA07063A

E. Iwama, P.L. Taberna, P. Azais, L. Brégeon, P. Simon, J. Power Sources 219(2012) 235-239.

doi: 10.1016/j.jpowsour.2012.07.029

D.Z. Chen, J. Yu, W. Lu, et al., Electrochim. Acta 233(2017) 181-189.

doi: 10.1016/j.electacta.2017.03.009

M. Steiger, S. Asmussen, Geochim. Cosmochim. Acta 72(2008) 4291-4306.

doi: 10.1016/j.gca.2008.05.053

A.A. Łatoszyńska, P.L. Taberna, P. Simon, W. Wieczorek, Electrochim. Acta 242(2017) 31-37.

doi: 10.1016/j.electacta.2017.04.122

Yuchen Wang , Yaoyu Liu , Xiongfei Huang , Guanjie He , Kai Yan . Fe nanoclusters anchored in biomass waste-derived porous carbon nanosheets for high-performance supercapacitor. Chinese Chemical Letters, 2024, 35(8): 109301-. doi: 10.1016/j.cclet.2023.109301

Wenhao Feng , Chunli Liu , Zheng Liu , Huan Pang . In-situ growth of N-doped graphene-like carbon/MOF nanocomposites for high-performance supercapacitor. Chinese Chemical Letters, 2024, 35(12): 109552-. doi: 10.1016/j.cclet.2024.109552

Junhan Luo , Qi Qing , Liqin Huang , Zhe Wang , Shuang Liu , Jing Chen , Yuexiang Lu . Non-contact gaseous microplasma electrode as anode for electrodeposition of metal and metal alloy in molten salt. Chinese Chemical Letters, 2024, 35(4): 108483-. doi: 10.1016/j.cclet.2023.108483

Zixuan Guo , Xiaoshuai Han , Chunmei Zhang , Shuijian He , Kunming Liu , Jiapeng Hu , Weisen Yang , Shaoju Jian , Shaohua Jiang , Gaigai Duan . Activation of biomass-derived porous carbon for supercapacitors: A review. Chinese Chemical Letters, 2024, 35(7): 109007-. doi: 10.1016/j.cclet.2023.109007

Yun Wei , Lei Zhou , Wenbin Hu , Liming Yang , Guang Yang , Chaoqiang Wang , Hui Shi , Fei Han , Yufa Feng , Xuan Ding , Penghui Shao , Xubiao Luo . Recovery of cathode copper and ternary precursors from CuS slag derived by waste lithium-ion batteries: Process analysis and evaluation. Chinese Chemical Letters, 2024, 35(7): 109172-. doi: 10.1016/j.cclet.2023.109172

Qiqi Li , Su Zhang , Yuting Jiang , Linna Zhu , Nannan Guo , Jing Zhang , Yutong Li , Tong Wei , Zhuangjun Fan . 前驱体机械压实制备高密度活性炭及其致密电容储能性能. Acta Physico-Chimica Sinica, 2025, 41(3): 2406009-. doi: 10.3866/PKU.WHXB202406009

Kuaibing Wang , Honglin Zhang , Wenjie Lu , Weihua Zhang . Experimental Design and Practice for Recycling and Nickel Content Detection from Waste Nickel-Metal Hydride Batteries. University Chemistry, 2024, 39(11): 335-341. doi: 10.12461/PKU.DXHX202403084

Huayan Liu , Yifei Chen , Mengzhao Yang , Jiajun Gu . Strategies for enhancing capacity and rate performance of two-dimensional material-based supercapacitors. Acta Physico-Chimica Sinica, 2025, 41(6): 100063-0. doi: 10.1016/j.actphy.2025.100063

Jingyu Shi , Xiaofeng Wu , Yutong Chen , Yi Zhang , Xiangyan Hou , Ruike Lv , Junwei Liu , Mengpei Jiang , Keke Huang , Shouhua Feng . Structure factors dictate the ionic conductivity and chemical stability for cubic garnet-based solid-state electrolyte. Chinese Chemical Letters, 2025, 36(5): 109938-. doi: 10.1016/j.cclet.2024.109938

Yuan Dong , Mutian Ma , Zhenyang Jiao , Sheng Han , Likun Xiong , Zhao Deng , Yang Peng . Effect of electrolyte cation-mediated mechanism on electrocatalytic carbon dioxide reduction. Chinese Chemical Letters, 2024, 35(7): 109049-. doi: 10.1016/j.cclet.2023.109049

Mengxiao Yang , Haicheng Huang , Shiyi Shen , Xinxin Liu , Mengyu Liu , Jiahua Guo , Fenghui Yang , Baoli Zha , Jiansheng Wu , Sheng Li , Fengwei Huo . Flexible aqueous zinc-ion battery with low-temperature resistant leather gel electrolyte. Chinese Chemical Letters, 2025, 36(6): 109988-. doi: 10.1016/j.cclet.2024.109988

Jianye Kang , Xinyu Yang , Xuhao Yang , Jiahui Sun , Yuhang Liu , Shutao Wang , Wenlong Song . Carbon dots-enhanced pH-responsive lubricating hydrogel based on reversible dynamic covalent bondings. Chinese Chemical Letters, 2024, 35(5): 109297-. doi: 10.1016/j.cclet.2023.109297

Xinyu Huai , Jingxuan Liu , Xiang Wu . Cobalt-Doped NiMoO4 Nanosheet for High-performance Flexible Supercapacitor. Chinese Journal of Structural Chemistry, 2023, 42(10): 100158-100158. doi: 10.1016/j.cjsc.2023.100158

Wen LUO , Lin JIN , Palanisamy Kannan , Jinle HOU , Peng HUO , Jinzhong YAO , Peng WANG . Preparation of high-performance supercapacitor based on bimetallic high nuclearity titanium-oxo-cluster based electrodes. Chinese Journal of Inorganic Chemistry, 2024, 40(4): 782-790. doi: 10.11862/CJIC.20230418

Hongren RONG , Gexiang GAO , Zhiwei LIU , Ke ZHOU , Lixin SU , Hao HUANG , Wenlong LIU , Qi LIU . High-performance supercapacitor based on 1D cobalt-based coordination polymer. Chinese Journal of Inorganic Chemistry, 2025, 41(6): 1183-1195. doi: 10.11862/CJIC.20250034

Sheng Zhao , Junjie Lu , Bifu Sheng , Siying Zhang , Hao Li , Jizhang Chen , Xiang Han . High-performance room temperature solid-state lithium battery enabled by PP-PVDF multilayer composite electrolyte. Chinese Chemical Letters, 2025, 36(6): 110008-. doi: 10.1016/j.cclet.2024.110008

Ningning Gao , Yue Zhang , Zhenhao Yang , Lijing Xu , Kongyin Zhao , Qingping Xin , Junkui Gao , Junjun Shi , Jin Zhong , Huiguo Wang . Ba2+/Ca2+ co-crosslinked alginate hydrogel filtration membrane with high strength, high flux and stability for dye/salt separation. Chinese Chemical Letters, 2024, 35(5): 108820-. doi: 10.1016/j.cclet.2023.108820

Ziling Jiang , Chen Liu , Jie Yang , Xia Li , Chaochao Wei , Qiyue Luo , Zhongkai Wu , Lin Li , Liping Li , Shijie Cheng , Chuang Yu . Designing F-doped Li3InCl6 electrolyte with enhanced stability for all-solid-state lithium batteries in a wide voltage window. Chinese Chemical Letters, 2025, 36(6): 109741-. doi: 10.1016/j.cclet.2024.109741

Xin Li , Ling Zhang , Yunyan Fan , Shaojing Lin , Yong Lin , Yongsheng Ying , Meijiao Hu , Haiying Gao , Xianri Xu , Zhongbiao Xia , Xinchuan Lin , Junjie Lu , Xiang Han . Carbon interconnected microsized Si film toward high energy room temperature solid-state lithium-ion batteries. Chinese Chemical Letters, 2025, 36(2): 109776-. doi: 10.1016/j.cclet.2024.109776

Xiaodan Wang , Yingnan Liu , Zhibin Liu , Zhongjian Li , Tao Zhang , Yi Cheng , Lecheng Lei , Bin Yang , Yang Hou . Highly efficient electrosynthesis of H2O2 in acidic electrolyte on metal-free heteroatoms co-doped carbon nanosheets and simultaneously promoting Fenton process. Chinese Chemical Letters, 2024, 35(7): 108926-. doi: 10.1016/j.cclet.2023.108926