Multi-bond Network Hydrogels with Robust Mechanical and Self-healable Properties

English

Multi-bond Network Hydrogels with Robust Mechanical and Self-healable Properties

-

The continuous combustion of unsustainable carbon-based fossil fuels has dramatically accelerated the increase in carbon dioxide (CO2) concentration in the atmosphere (from approximately 278.3 ppm in 1750 to 417.9 ppm in 2023), which would exacerbate environmental problems such as greenhouse effect [1]. The effective electrosynthesis of high value-added multi-carbon (C2+) chemicals (e.g., ethanol, ethylene) from CO2 reduction reaction (CO2RR) is a promising strategy to mitigate these environmental issues mentioned above but remains highly challenging due to the competition of hydrogen evolution reaction (HER) and low selectivity of target products. Cu-based catalysts have been widely studied because of the optimal adsorption of *CO intermediates and thus promoting C—C coupling. However, the low selectivity, deficient Faraday efficiency (FE) and unsatisfactory partial current densities of target products still cannot meet industrial requirements.

In order to enhance the selectivity and activity of Cu-based catalysts to C2+ chemicals, heterogeneous elements have been introduced to construct bimetallic alloys with redistributed electronic structures and optimized binding energies of intermediates. Compared to common disordered alloys, Cu-based structurally ordered intermetallic alloys have been reported to exhibit superior selectivity and activity as well as stability in CO2RR towards C2+ products (e.g., acetate) owing to the unique electronic structures originating from ordered atomic arrangement and more negative formation energy [2]. Therefore, constructing intermetallic alloy via phase engineering may be a promising strategy to achieve efficient and stable CO2RR towards C2+ products. Currently, most of researches focus on developing electrocatalysts based on conventional body-centered cubic (e.g., PdCu, NiCu with B2 phase) and cubic close-packed ordered structures (e.g., Cu3Pt, Cu3Au with L12 phase), there is still a lot of room for performance improvement [3]. Since catalytic activity/stability is closely related to atomic distribution, bond strength, coordination environments, electronic structures, etc., which are determined by phase structures, it is significant to investigate and rationally design innovative catalysts with unconventional crystal phases. Among various unconventional phases, topological close-packed Frank-Kasper phases (A15, C15, C14, σ, etc.) with higher coordination numbers (e.g., 8 for body-centered cubic structures, 12 for cubic close-packed structures and 12, 14, 15, 16 for topological close-packed structures), lager packing densities (> 0.74), unique electronic structures, larger corrosion energy barriers (e.g., 0.84, 1.07, and 2.77 eV for L12-Pt3Ni, L10-PtNi, and C14-Fe2Ni, respectively) and more negative formation energy (e.g., −0.566, −1.022, and −1.084 eV for L10-PtZn, D024-Pt3Zr, and C15-Pt2Y, respectively) may exhibit promoted activity and stability towards CO2RR to C2+ chemicals [4].

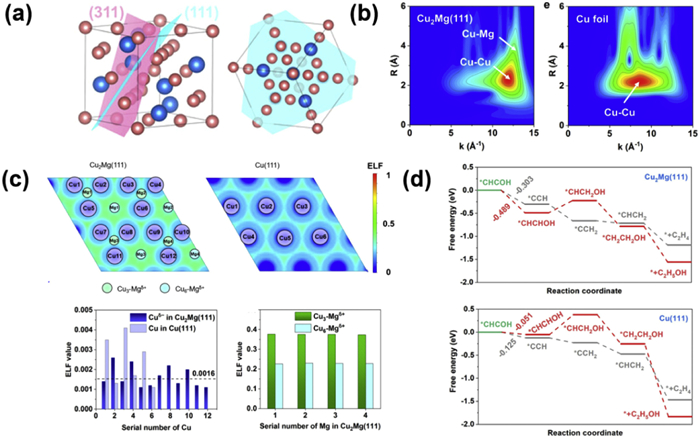

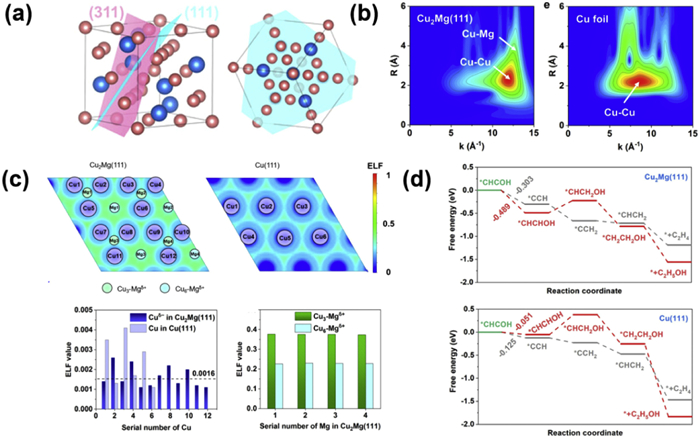

Recently, Prof. Gengfeng Zheng et al. proposed a phase engineering strategy to develop the topological close-packed C15 Cu2Mg intermetallic alloy with high-density ordered active Cu sites, which achieved high FEC2H5OH, current density and stability in CO2RR simultaneously [5]. The C15 Cu2Mg possesses a space group of Fd3m and lattice spacing of 0.405 nm corresponding to the (111) planes, differing from the disordered cubic close-packed solid solution Mg-doped Cu (Mg0.1Cu, Fm3m space group, 0.219 nm lattice spacing corresponding to the (111) planes) and pure Cu (Fm3m space group, 0.21 nm lattice spacing corresponding to the (111) planes) (Figs. 1a and b). Additionally, two types of Mg atoms are embraced by Cu6 and Cu3 rings in C15 Cu2Mg, which allows to expose abundant Cu edges and provide more active sites for CO2RR. Compared with pure Cu and disordered Mg0.1Cu, due to the difference in electronegativity and phase structure, more electrons can transfer from Mg to Cu in C15 Cu2Mg, thereby leading to a negative shift of d-band center of Cu and optimization of electronic distribution (Fig. 1c). The negative shift of d-band center of Cu can reduce the energy barriers of *CO-*CO coupling, thus enhancing the selectivity of C2+products. During the CO2RR tests, the C15 Cu2Mg catalyst exhibits much lower overpotential (only −0.84 V to achieve jtotal of −600 mA/cm2), much higher FEC2H5OH (76.2% ± 4.8%) and cathodic energy efficiency (42.1% ± 2.6%), far exceeding the disordered Mg0.1Cu (main product is CH4 with FECH4 no > 60%). Moreover, the C15 Cu2Mg displays durable FEC2H5OH (> 80%) in the jtotal range from −200 mA/cm2 to −600 mA/cm2 and maintains its high FEC2H5OH (61%) after 15 h of continuous reaction at −600 mA/cm2.

Figure 1

Figure 1. (a) Schematic of C15 Cu2Mg intermetallic compound. (b) Wavelet-transform of the k2-weighted of Cu K-edge extended X-ray absorption fine structure (EXAFS) data of C15 Cu2Mg and Cu foil samples. (c) Electronic localization function (ELF) and extracted ELF value of C15 Cu2Mg and Cu model. (d) Energy diagrams of hydrogenation of *CHCOH intermediate to form ethanol and ethylene on C15 Cu2Mg and Cu models. Reprinted with permission [5]. Copyright 2024, Wiley-VCH.

Figure 1. (a) Schematic of C15 Cu2Mg intermetallic compound. (b) Wavelet-transform of the k2-weighted of Cu K-edge extended X-ray absorption fine structure (EXAFS) data of C15 Cu2Mg and Cu foil samples. (c) Electronic localization function (ELF) and extracted ELF value of C15 Cu2Mg and Cu model. (d) Energy diagrams of hydrogenation of *CHCOH intermediate to form ethanol and ethylene on C15 Cu2Mg and Cu models. Reprinted with permission [5]. Copyright 2024, Wiley-VCH.To further investigate the reaction mechanism, density functional theory (DFT) calculations were performed. The variation of energy from *CHCOH to *CHCHOH or *CCH was used as a descriptor to explore the ethanol and ethylene pathways. The C15 Cu2Mg possesses a lower energy barrier from *CHCOH to *CHCHOH than to *CCH, thus exhibiting high selectivity for ethanol. In contrast, pure Cu and disordered Mg0.1Cu prefer the ethylene pathway (Fig. 1d). Furthermore, the CH4 pathway was also researched by comparing energy difference from CO2 to *COOH and from *CO to *CHO. The C15 Cu2Mg displayed a higher energy barrier than its counterparts (pure Cu and disordered Mg0.1Cu), thus showing lower FECH4. The above experimental results and theoretical calculations verify the superior activity, selectivity and stability of C15 Cu2Mg catalysts in CO2RR towards ethanol to commercial Cu and disordered Mg0.1Cu.

Prospectively, the performance of unconventional intermetallic alloys for CO2RR should be further evaluated in real devices, especially in proton-exchange membranes (PEM) based devices due to their prominent thermodynamic stability and corrosion resistance. Additionally, more unconventional phases with optimal atomic distribution, coordination environments and electronic structure should be explored and applied as electrocatalysts in CO2RR. Moreover, the correlations between crystal phases and electrocatalytic performance remain ambiguous. It is of significance to build bridges among the phase structure, electronic distribution and electrocatalytic performance via rationally designing and comparing catalysts with different crystal phases.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

CRediT authorship contribution statement

Qiyan Wu: Methodology, Investigation, Data curation, Conceptualization. Qing Li: Supervision, Resources, Methodology, Formal analysis, Conceptualization.

-

-

[1]

Vermonden, T., Censi, R. and Hennink, W.E., Chem. Rev., 2012, 112(5):2853 doi: 10.1021/cr200157d

-

[2]

Collier, J.H., Soft Matter, 2008, 4(12):2310 doi: 10.1039/b805563g

-

[3]

Dankers, P.Y.W., Harmsen, M.C., Brouwer, L.A., van Luyn, M.J.A. and Meijer, E.W., Nat. Mater., 2005, 4(7):568 doi: 10.1038/nmat1418

-

[4]

Lee, K.Y. and Mooney, D.J., Chem. Rev., 2001, 101(7):1869 doi: 10.1021/cr000108x

-

[5]

Buenger, D., Topuz, F. and Groll, J., Prog. Polym. Sci., 2012, 37(12):1678 doi: 10.1016/j.progpolymsci.2012.09.001

-

[6]

Liang, D., Agarwal, A.K., Beebe, D.J. and Hongrui, J., Nature, 2006, 442(7102):551 doi: 10.1038/nature05024

-

[7]

Erdodi, G. and Kennedy, J.P., Prog. Polym. Sci., 2006, 31(1):1 doi: 10.1016/j.progpolymsci.2005.11.001

-

[8]

Sakai, T., Matsunaga, T., Yamamoto, Y., Ito, C., Yoshida, R., Suzuki, S., Sasaki, N., Shibayama, M. and Chung, U., Macromolecules, 2008, 41(14):5379 doi: 10.1021/ma800476x

-

[9]

Okumura, Y. and Ito, K., Adv. Mater., 2001, 13(7):485 doi: 10.1002/(ISSN)1521-4095

-

[10]

Naghash, H.J. and Okay, O., J. Appl. Polym. Sci., 1996, 60(7):971 doi: 10.1002/(ISSN)1097-4628

-

[11]

Gong, J.P., Soft Matter, 2010, 6(12):2583 doi: 10.1039/b924290b

-

[12]

Malkoch, M., Vestberg, R., Gupta, N., Mespouille, L., Dubois, P., Mason, A.F., Hedrick, J.L., Liao, Q., Frank, C.W., Kingsbury, K. and Hawker, C.J., Chem. Commun., 2006(26):2774 doi: 10.1039/b603438a

-

[13]

Ito, K., Polym. J., 2007, 39(6):489 doi: 10.1295/polymj.PJ2006239

-

[14]

Gong, J.P., Katsuyama, Y., Kurokawa, T. and Osada, Y., Adv. Mater., 2003, 15(14):1155 doi: 10.1002/adma.200304907

-

[15]

Haraguchi, K., Takehisa, T. and Fan, S., Macromolecules, 2002, 35(27):10162 doi: 10.1021/ma021301r

-

[16]

Yang, J., Wang, X.P. and Xie, X.M., Soft Matter, 2012, 8(4):1058 doi: 10.1039/C1SM06647A

-

[17]

Liu, J.Q., Chen, C.F., He, C.C., Zhao, J., Yang, X.J. and Wang, H.L., ACS Nano, 2012, 6(9):8194 doi: 10.1021/nn302874v

-

[18]

Shi, F.K., Wang, X.P., Guo, R.H., Zhong, M. and Xie, X.M., J. Mater. Chem. B, 2015, 3(7):1187 doi: 10.1039/C4TB01654H

-

[19]

Zhong, M., Liu, X.Y., Shi, F.K., Zhang, L.Q., Wang, X.P., Cheetham, A.G., Cui, H.G. and Xie, X.M., Soft Matter, 2015, 11(21):4235 doi: 10.1039/C5SM00493D

-

[20]

Tuncaboylu, D.C., Argun, A., Sahin, M., Sari, M. and Okay, O., Polymer, 2012, 53(24):5513 doi: 10.1016/j.polymer.2012.10.015

-

[21]

Huang, T., Xu, H.G., Jiao, K.X., Zhu, L.P., Brown, H.R. and Wang, H.L., Adv. Mater., 2007, 19(12):1622 doi: 10.1002/(ISSN)1521-4095

-

[22]

Sun, J., Zhao, X., Illeperuma, W.R.K., Chaudhuri, O., Oh, K.H., Mooney, D.J., Vlassak, J.J. and Suo, Z., Nature, 2012, 489(7414):133 doi: 10.1038/nature11409

-

[23]

Zhong, M., Shi, F.K., Liu, Y.T., Liu, X.Y. and Xie, X.M., Chinese Chem. Lett., 2016, 27(3):312 doi: 10.1016/j.cclet.2015.12.020

-

[24]

Shi, F.K., Zhong, M., Zhang, L.Q., Liu, X.Y. and Xie, X.M., J. Mater. Chem. B, 2016, 4(37):6221 doi: 10.1039/C6TB01606E

-

[25]

Zhang, L.Q., Chen, L.W., Zhong, M., Shi, F.K., Liu, X.Y. and Xie, X.M., Chinese J. Polym. Sci., 2016, 34(10):1261 doi: 10.1007/s10118-016-1848-7

-

[26]

Shi, F.K., Zhong, M., Zhang, L.Q., Liu, X.Y. and Xie, X.M., Acta Polymerica Sinica (in Chinese), 2017, (3):491

-

[27]

Zhong, M., Liu, Y.T. and Xie, X.M., J. Mater. Chem. B, 2015, 3(19):4001 doi: 10.1039/C5TB00075K

-

[28]

Zhong, M., Liu, Y.T., Liu, X.Y., Shi, F.K., Zhang, L.Q., Zhu, M. and Xie, X.M., Soft Matter, 2016, 12(24):5420 doi: 10.1039/C6SM00242K

-

[29]

Taylor, D.L. and Panhuis, M.I.H., Adv. Mater., 2016, 28(41):9060 doi: 10.1002/adma.201601613

-

[30]

Phadke, A., Zhang, C., Arman, B., Hsu, C., Mashelkar, R.A., Lele, A.K., Tauber, M.J., Arya, G. and Varghese, S., Proc. Natl. Acad. Sci., 2012, 109 (12):4383 doi: 10.1073/pnas.1201122109

-

[31]

Dai, X.Y., Zhang, Y.Y., Gao, L.N., Bai, T., Wang, W., Cui, Y.L. and Liu, W.G., Adv. Mater., 2015, 27(23):3566 doi: 10.1002/adma.v27.23

-

[32]

Tuncaboylu, D.C., Sahin, M., Argun, A., Oppermann, W. and Okay, O., Macromolecules, 2012, 45(4):1991 doi: 10.1021/ma202672y

-

[33]

Haraguchi, K., Uyama, K. and Tanimoto, H., Macromol. Rapid Commun., 2011, 32(16):1253 doi: 10.1002/marc.v32.16

-

[34]

Gao, G.R., Du, G.L., Sun, Y.N. and Fu, J., ACS Appl. Mater. Interfaces, 2015, 7(8):5029 doi: 10.1021/acsami.5b00704

-

[35]

Liu, J.Q., Song, G.S., He, C.C. and Wang, H.L., Macromol. Rapid Commun., 2013, 34(12):1002 doi: 10.1002/marc.v34.12

-

[36]

Zhang, H.J., Xia, H.S. and Zhao, Y., ACS Macro Lett., 2012, 1(11):1233 doi: 10.1021/mz300451r

- [37]

-

[38]

Yoshizawa, S., Takehara, Z., Ogumi, Z. and Nagai, C., J. Appl. Electrochem., 1976, 6(2):147 doi: 10.1007/BF00615380

-

[39]

Wei, Z., He, J., Liang, T., Oh, H., Athas, J., Tong, Z., Wang, C. and Nie, Z., Polym. Chem., 2013, 4(17):4601 doi: 10.1039/c3py00692a

-

[40]

Hernandez, S., Papp, J.K. and Bhattacharyya, D., Ind. Eng. Chem. Res., 2014, 53(3):1130 doi: 10.1021/ie403353g

-

[41]

Zheng, S.Y., Ding, H., Qian, J., Yin, J., Wu, Z.L., Song, Y. and Zheng, Q., Macromolecules, 2016, 49(24):9637 doi: 10.1021/acs.macromol.6b02150

-

[42]

Zhao, X.H., Soft Matter, 2014, 10(5):672 doi: 10.1039/C3SM52272E

-

[43]

Sun, T.L., Kurokawa, T., Kuroda, S., Ihsan, A.B., Akasaki, T., Sato, K., Haque, M.A., Nakajima, T. and Gong, J.P., Nat. Mater., 2013, 12(10):932 doi: 10.1038/nmat3713

-

[44]

Deplace, F., Rabjohns, M.A., Yamaguchi, T., Foster, A.B., Carelli, C., Lei, C., Ouzineb, K., Keddie, J.L., Lovell, P.A. and Creton, C., Soft Matter, 2009, 5(7):1440 doi: 10.1039/b815292f

-

[1]

-

计量

- PDF下载量: 0

- 文章访问数: 1040

- HTML全文浏览量: 37

DownLoad:

DownLoad:

下载:

下载: